5.4 Meshing Schemes

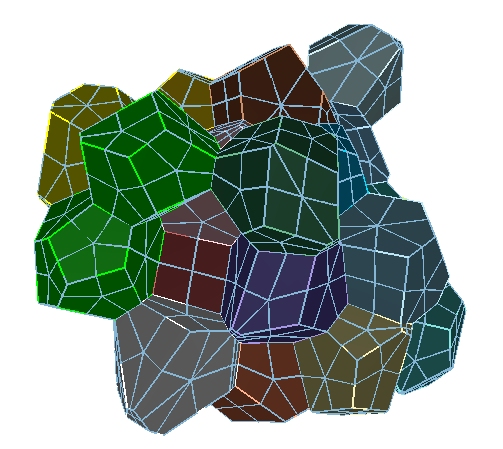

Meshing schemes in Cubit can be divided into four broad categories as detailed in the following sections.

If no scheme is selected, Cubit will attempt to assign a scheme using the automatic scheme selection methods.

5.4.1 Traditional Meshing Schemes

Traditional meshing schemes are used to apply a mesh to an existing geometry using the methods described in Meshing the Geometry (i.e. setting a scheme, applying interval sizes, and meshing). Traditional meshing schemes are available for all geometry types.

|

5.4.2 Free Meshing Schemes

Free meshing schemes will create a free-standing mesh without any prior existing geometry. The final mesh will have mesh-based geometry.

5.4.3 Conversional Meshing Schemes

Conversional meshing schemes are used to convert an existing mesh into a mesh of different element type or size. For example, the THex scheme will convert a tetrahedral mesh into a hexahedral mesh.

5.4.4 Duplication Meshing Schemes

Duplication meshing schemes are used to copy an existing mesh from one geometry onto another similar geometry.

5.4.5 Parallel Meshing Scheme

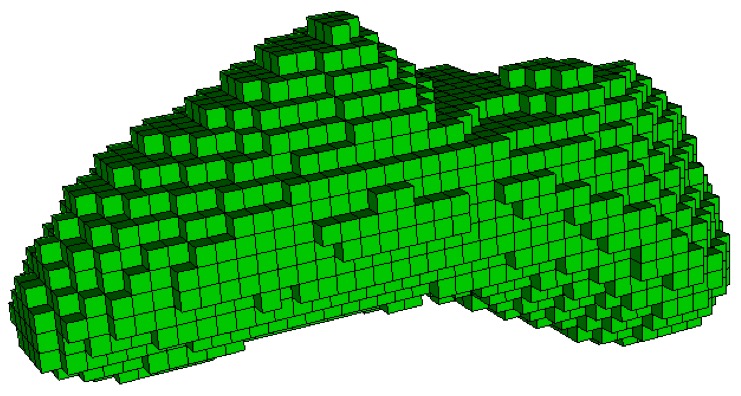

The Sculpt algorithm is an all-hex, automatic, parallel meshing scheme available in the Cubit Pro version.

5.4.6 General Meshing Information

Information on specific mesh schemes available in Cubit is given in this section. The following sections have important meshing-related information as well, and should be read before applying any of the mesh schemes described below.

In most cases, meshing a geometric entity in Cubit consists of three steps:

Set the interval number or size for the entity (See Interval Assignment.)

Set the scheme for the object, along with any scheme-specific information, using the scheme setting commands described below.

Mesh the object, using the command:

Mesh {geom_list}

After meshing is completed, the mesh quality is automatically checked (see Mesh Quality Assessment), then the mesh is drawn in the graphics window.

The following table classifies the meshing schemes with respect to their applicable geometry.

|

|

|

5.4.7 Automatic Scheme Selection

{geom_list} Scheme Auto

5.4.7.1 Default Scheme Selection

If the user does not set a scheme for a particular entity and chooses to mesh the entity, Cubit will automatically run the auto scheme selection algorithm and attempt to set a scheme. In cases where the auto scheme selection fails to choose a scheme, the meshing operation will fail. In this case explicit specification of the meshing scheme and/or further geometry decomposition may be necessary.

Set Default Element [Tet|Tri|HEX|QUAD|None]

Previous functionality of Cubit used a default scheme of map and interval of 1 for all surface and volume entities. For backwards compatibility and if this behavior is still desired, the none option may be used on the set default element command.

5.4.7.2 Auto Scheme Selection General Notes

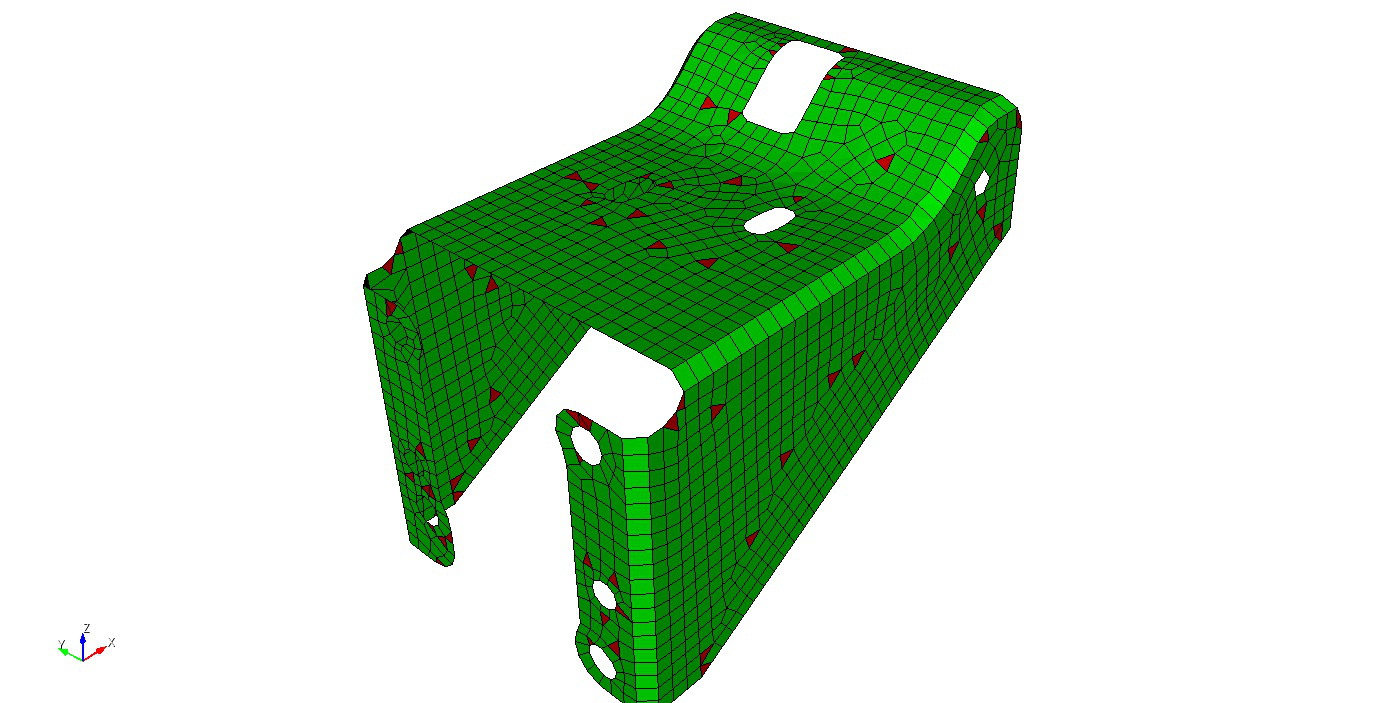

In general, automatic scheme selection reduces the amount of user input. If the user knows the model consists of 2.5D meshable volumes, three commands to generate a mesh after importing or creating the model are needed.

To automatically calculate the meshing scheme

On the Command Panel, click on Mesh and then Volume.

Click on the Mesh action button.

Enter the appropriate value for Select Volumes. This can also be done using the Pick Widget function.

Select Automatically Calculate from the drop-down menu.

Click Apply Scheme then click Mesh.

volume all size <value>

volume all scheme auto

mesh volume all

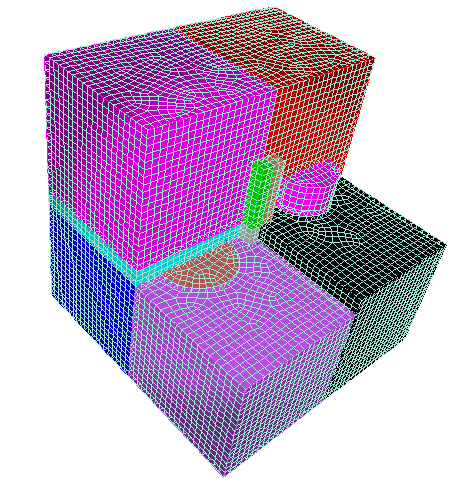

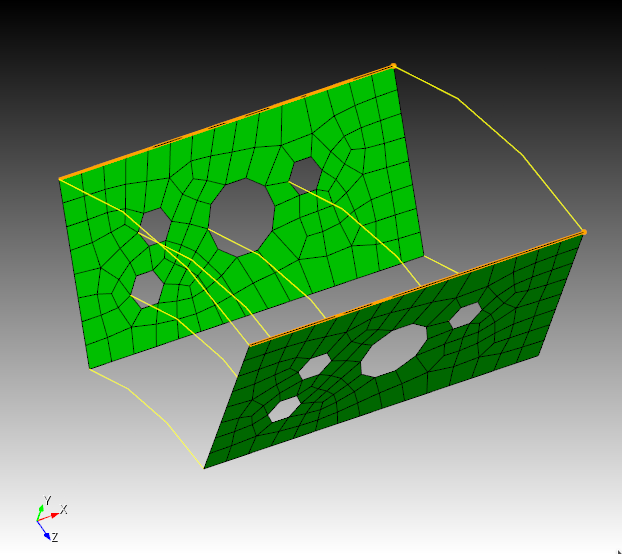

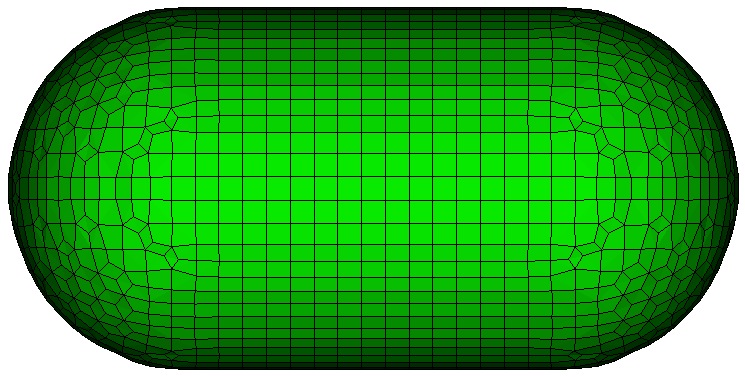

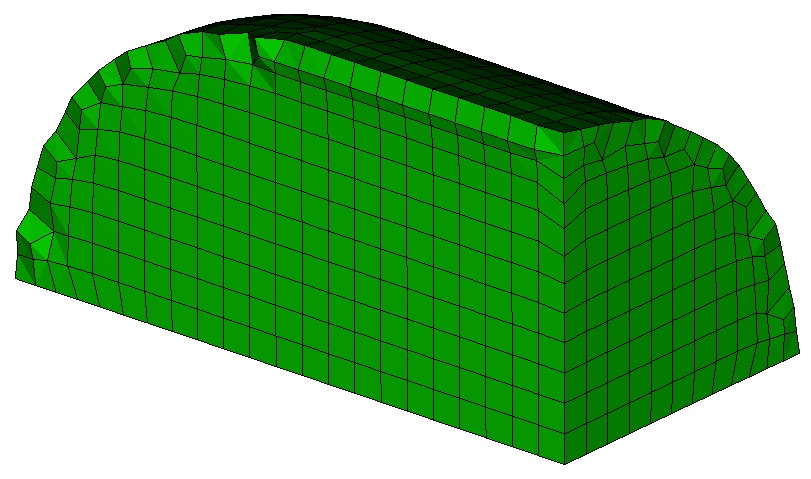

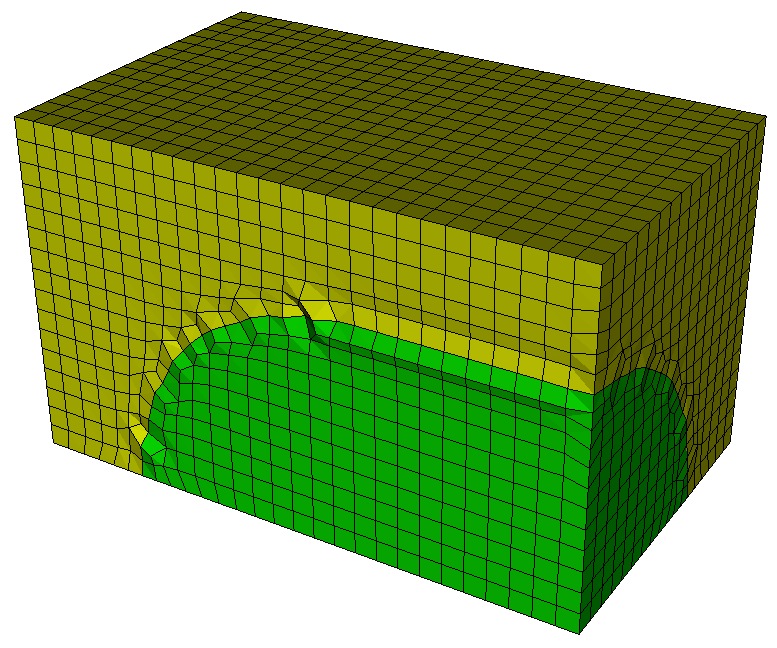

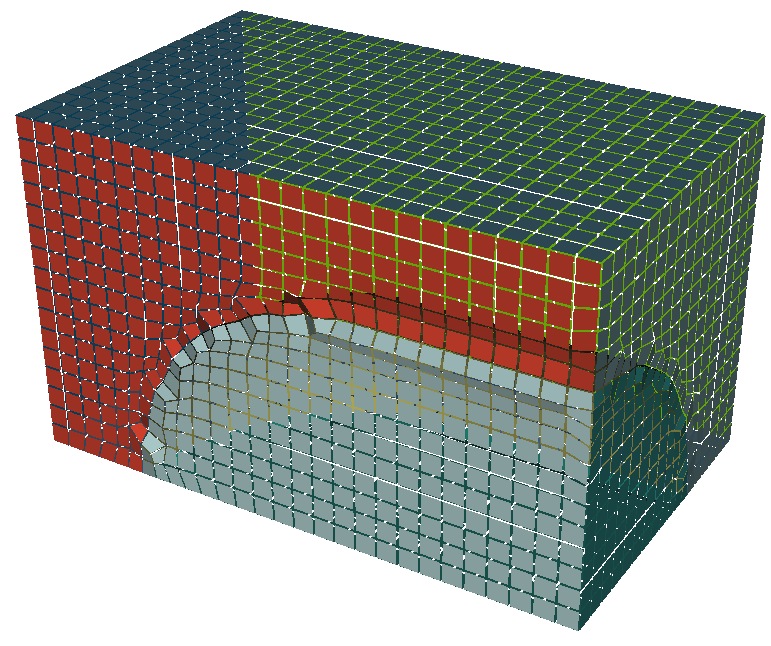

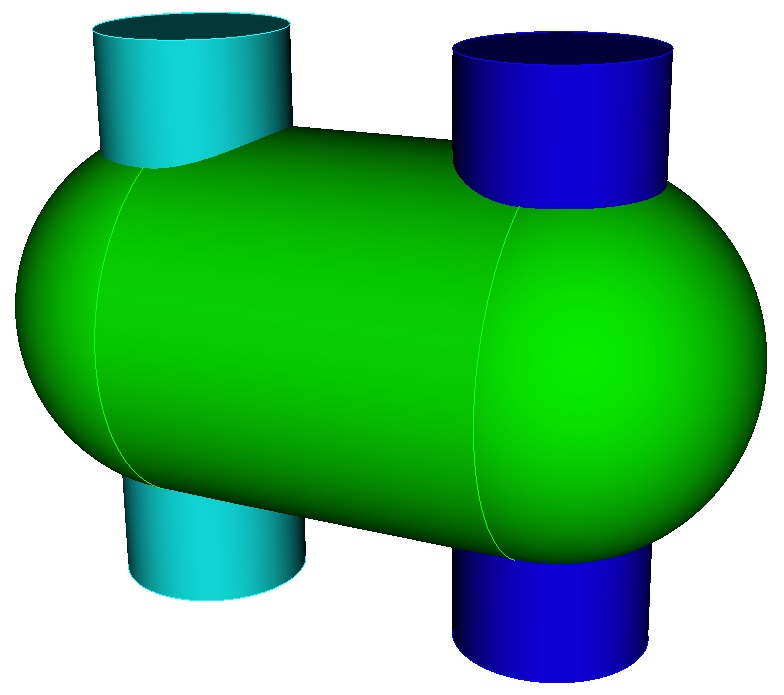

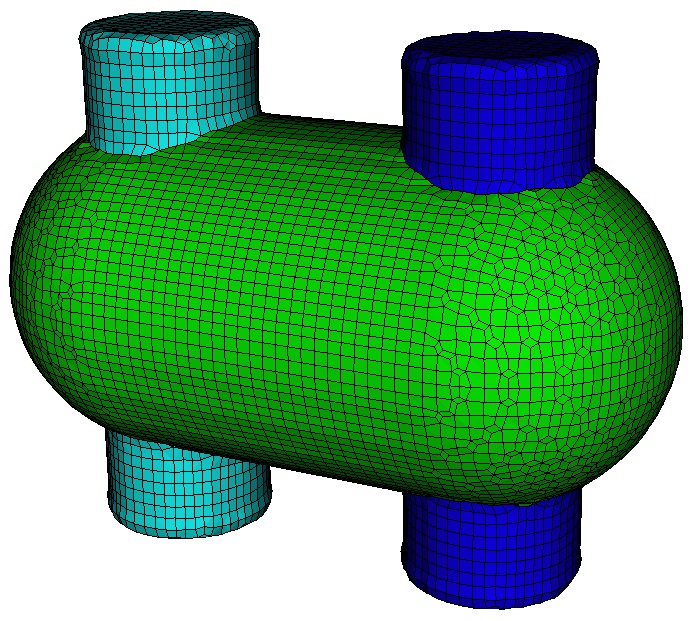

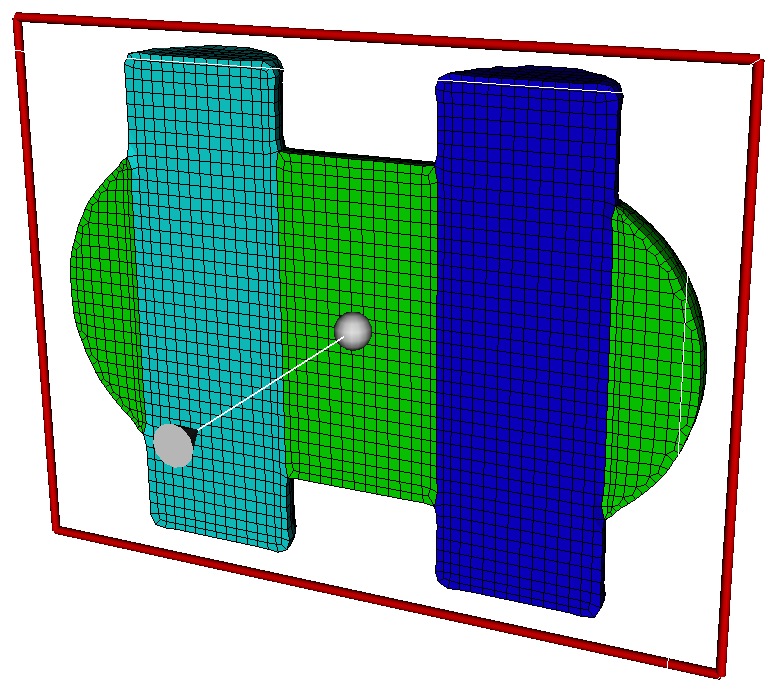

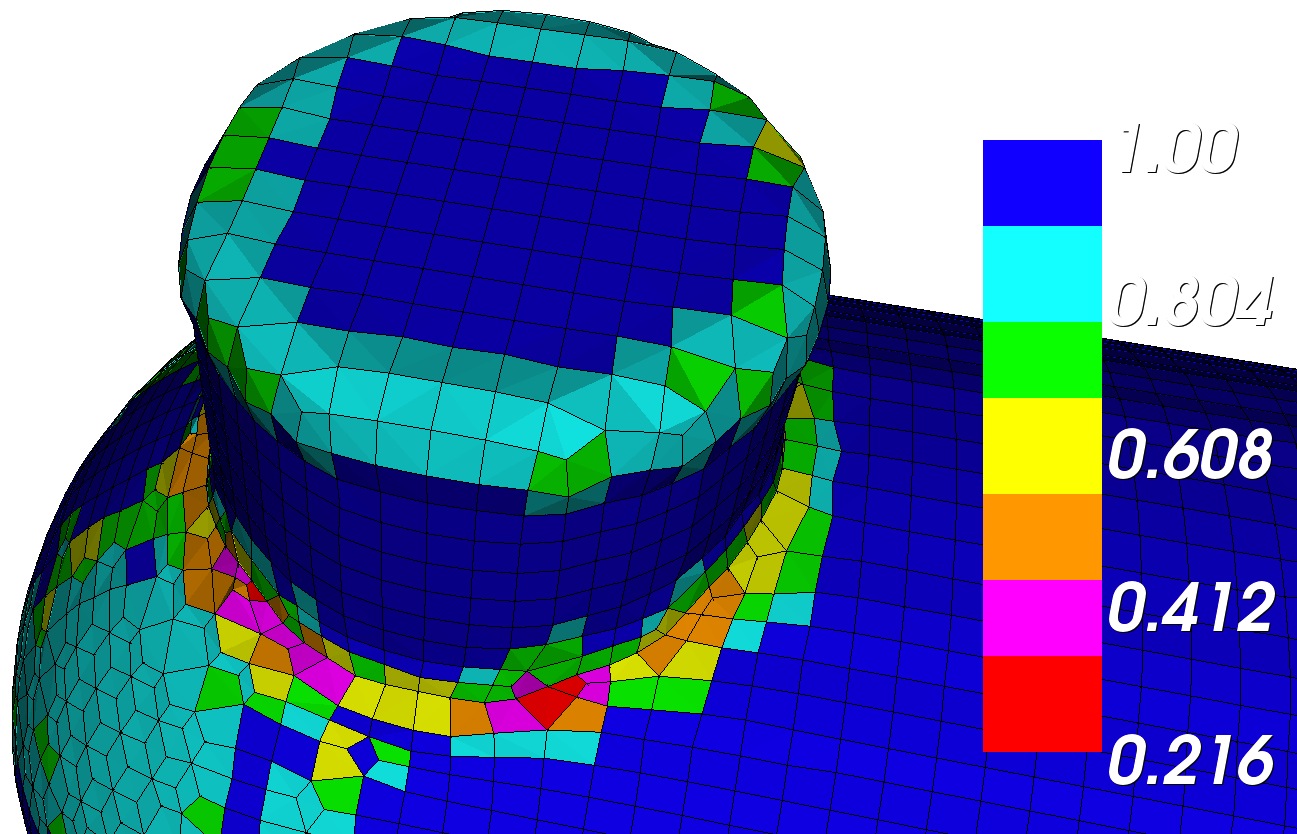

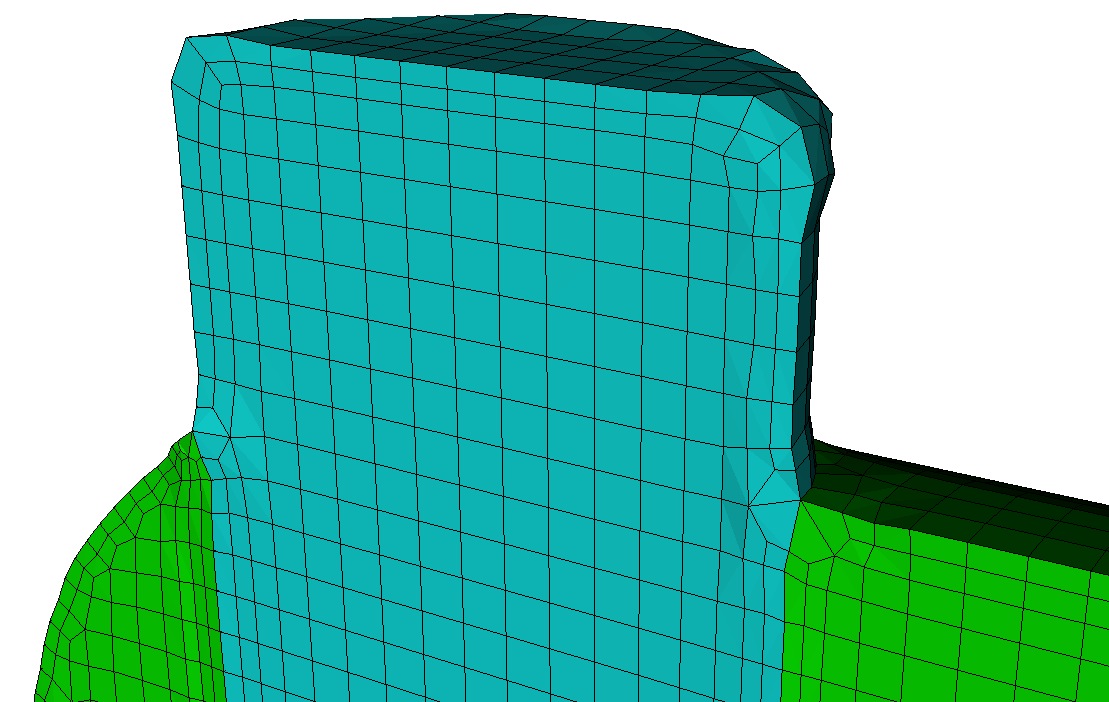

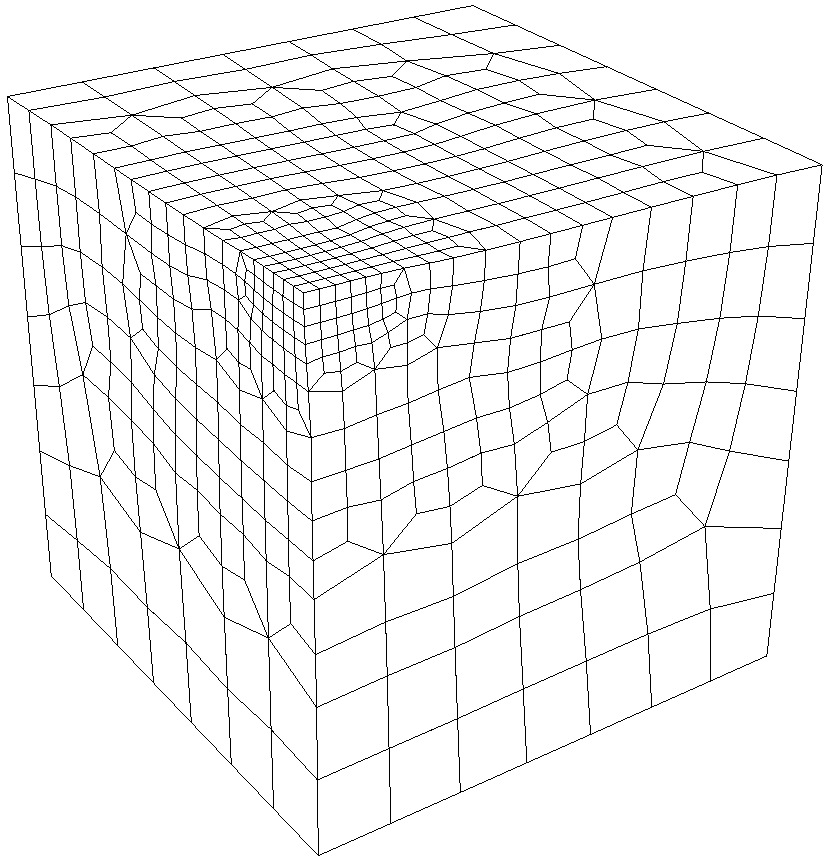

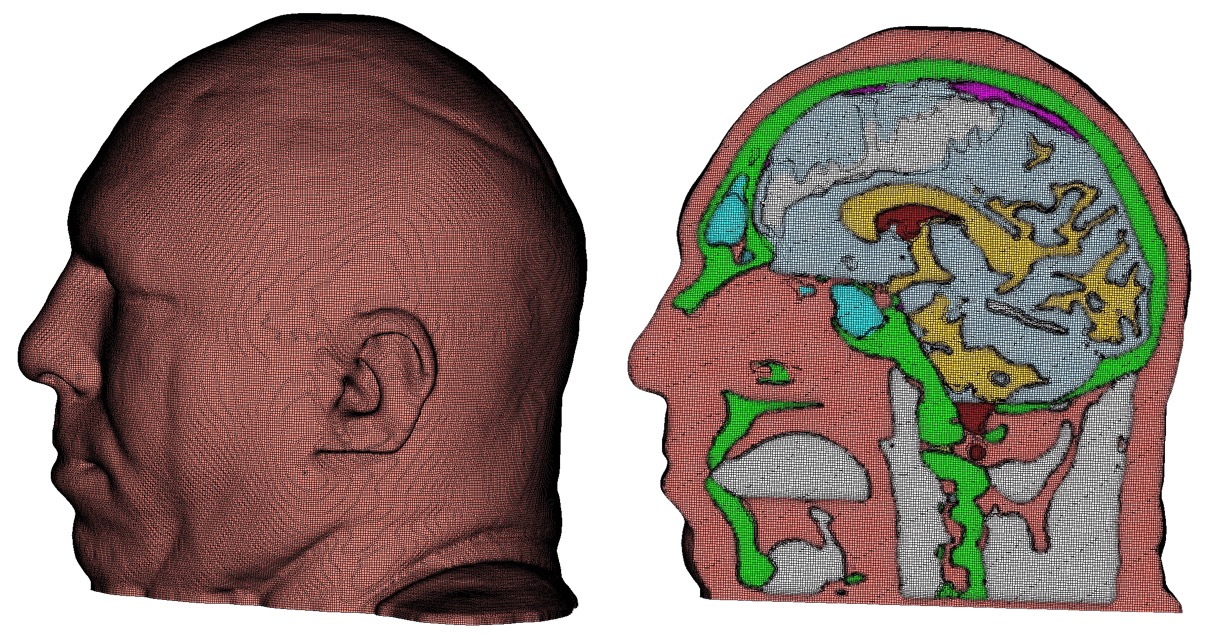

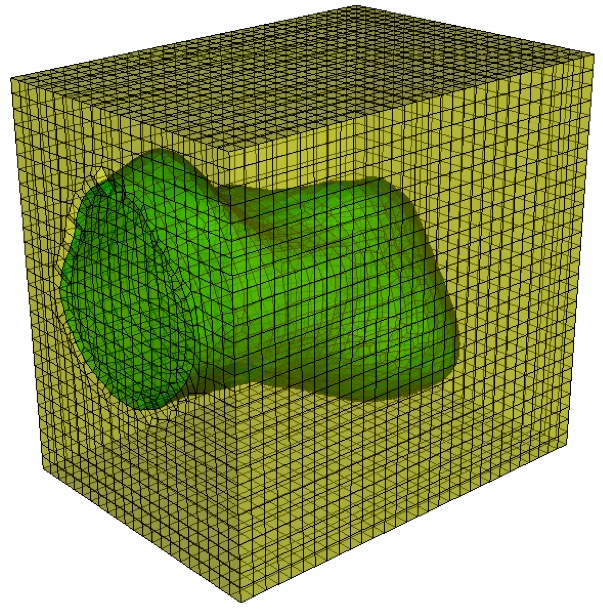

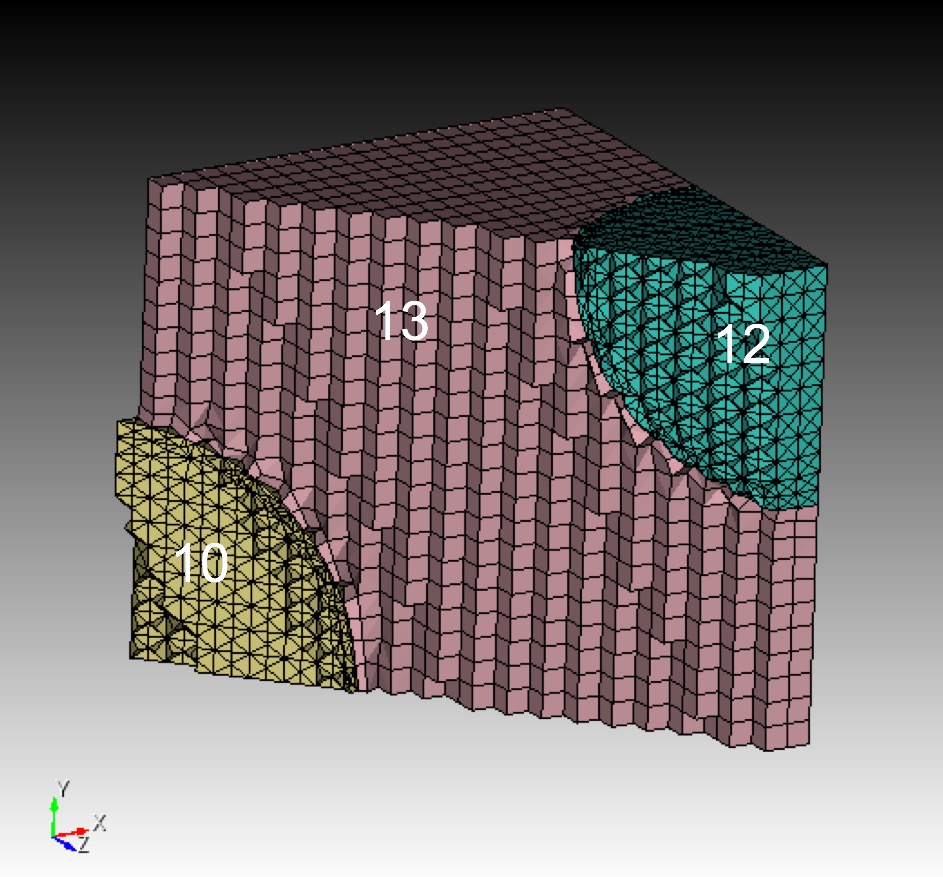

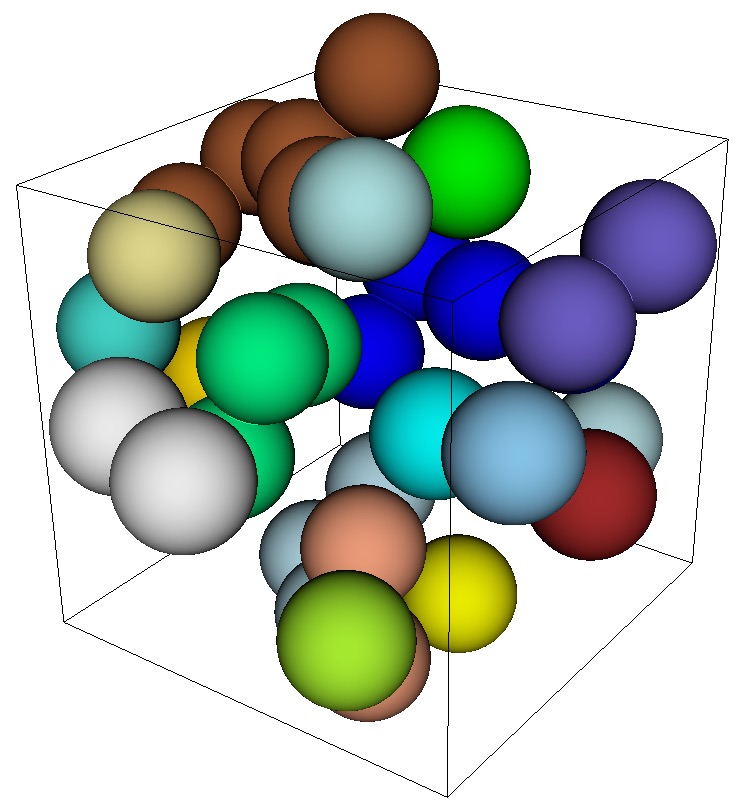

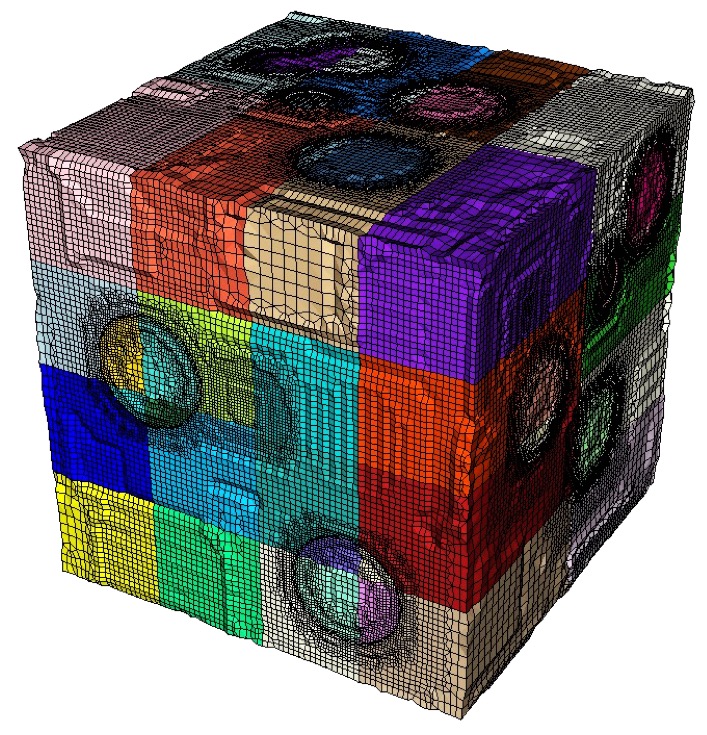

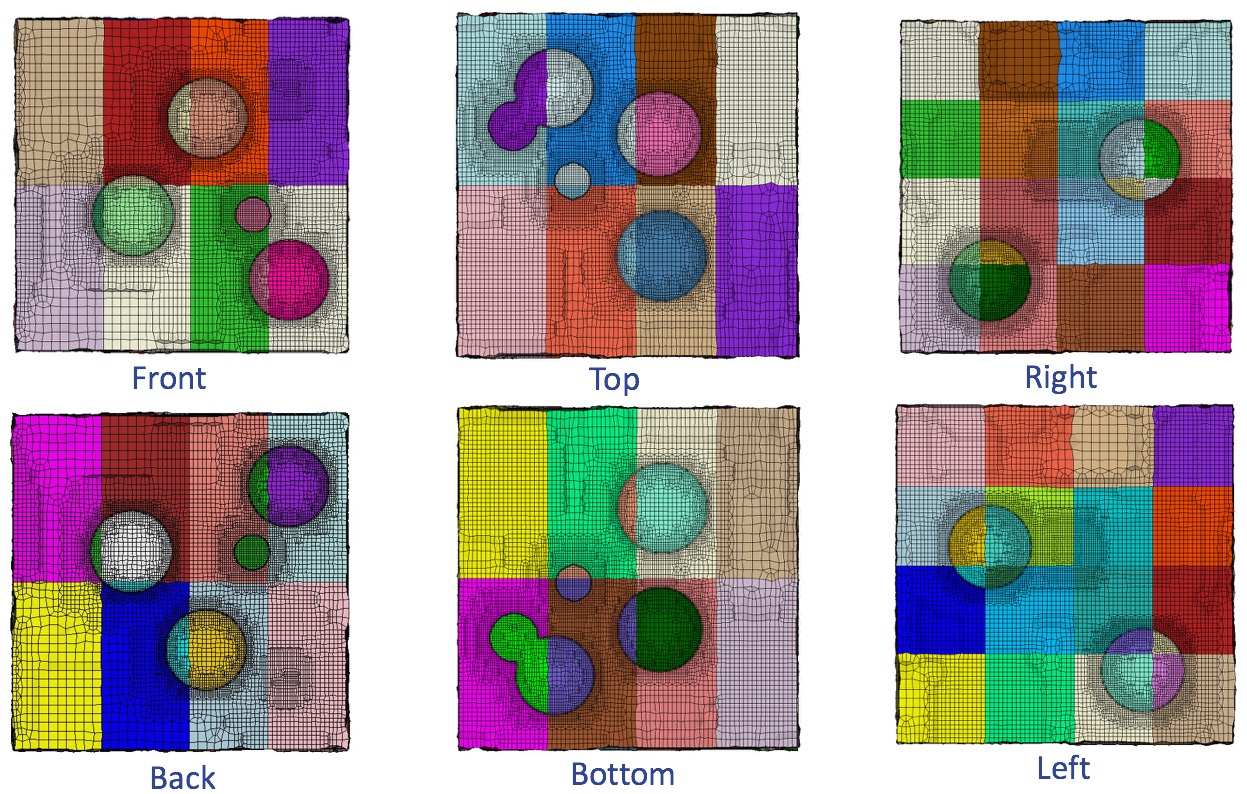

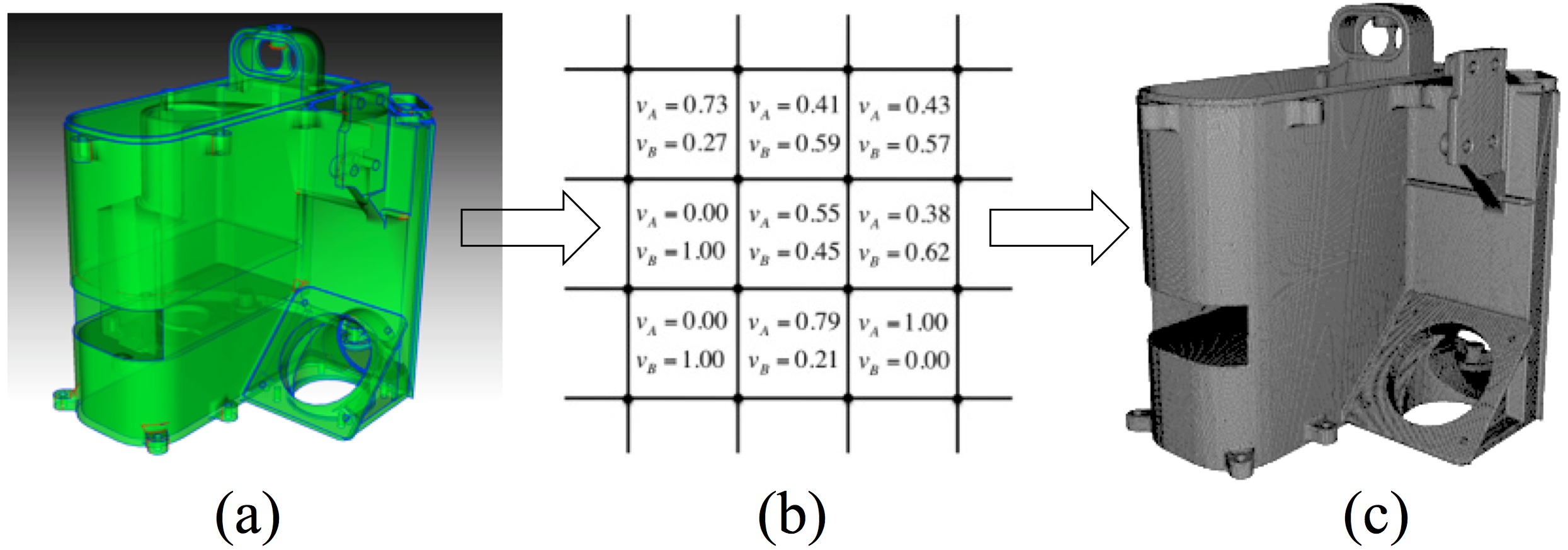

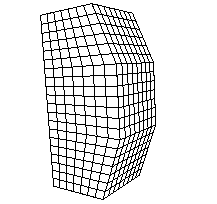

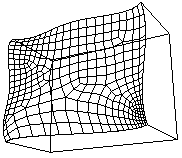

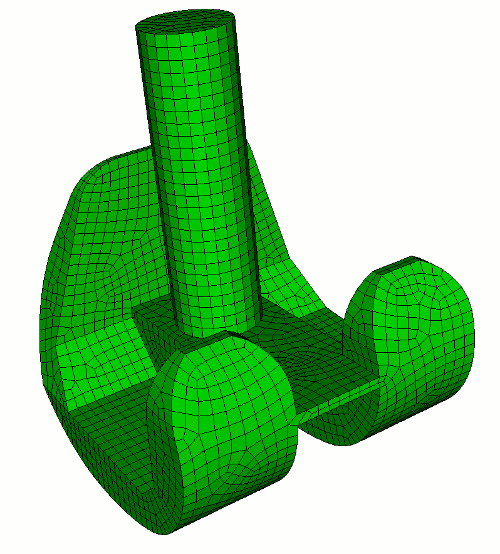

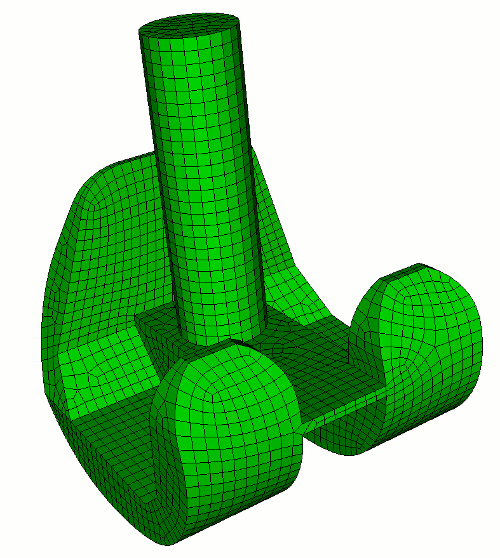

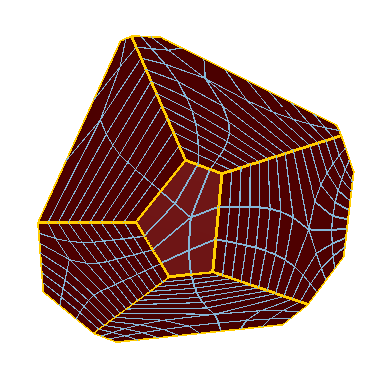

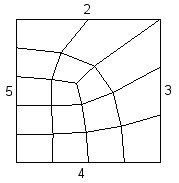

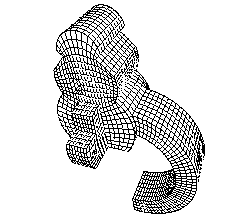

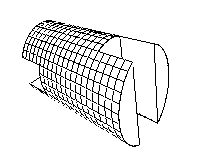

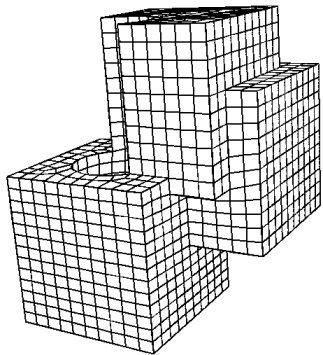

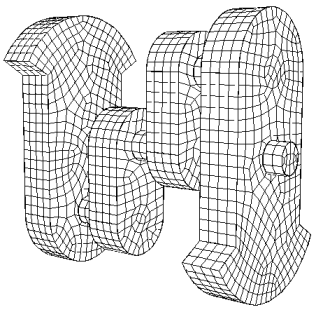

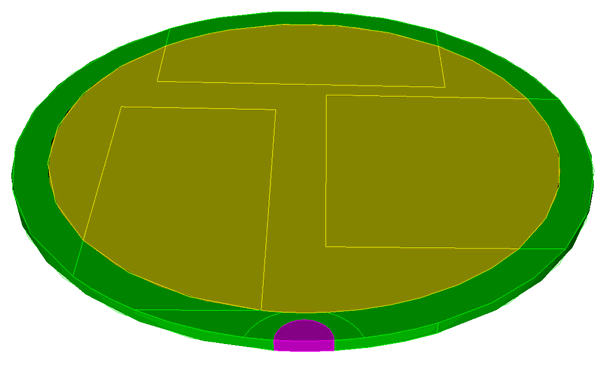

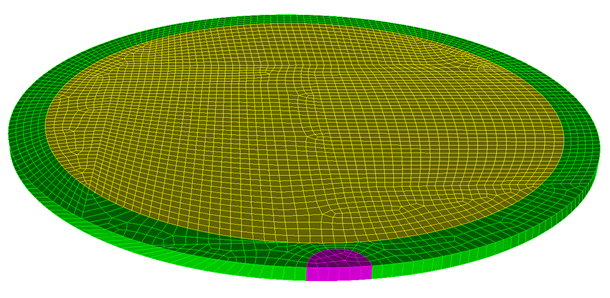

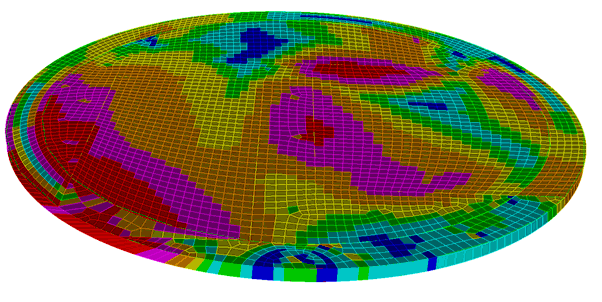

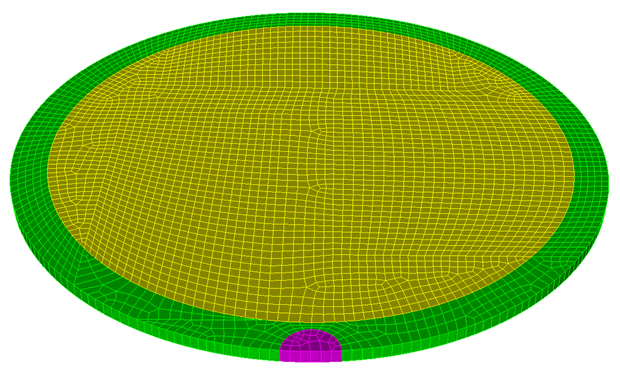

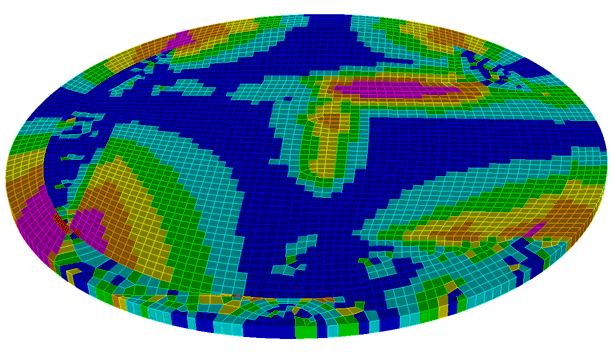

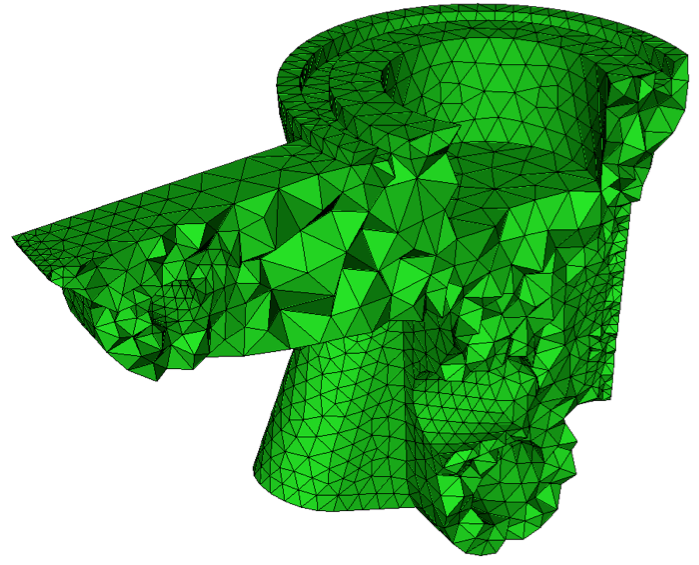

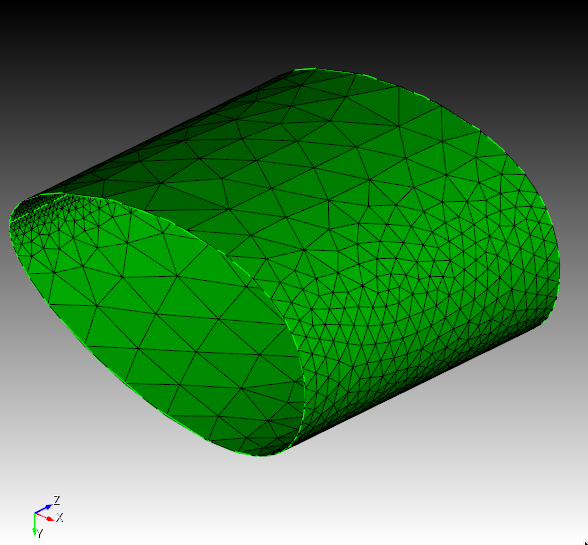

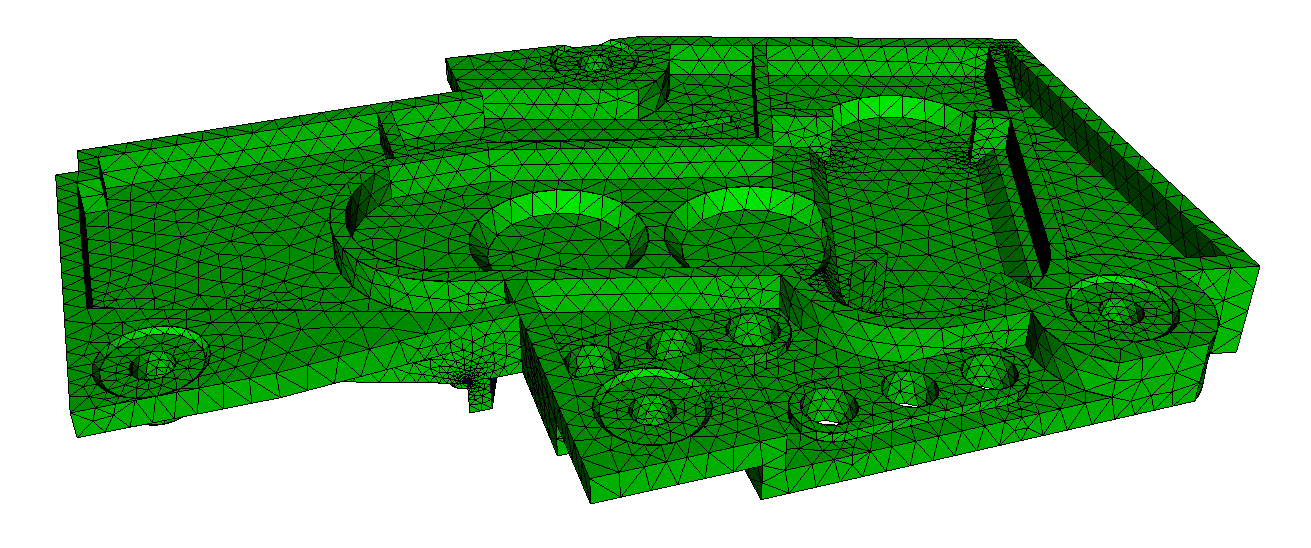

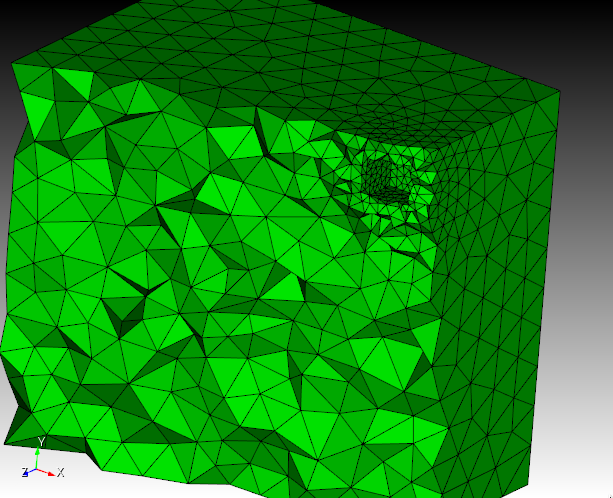

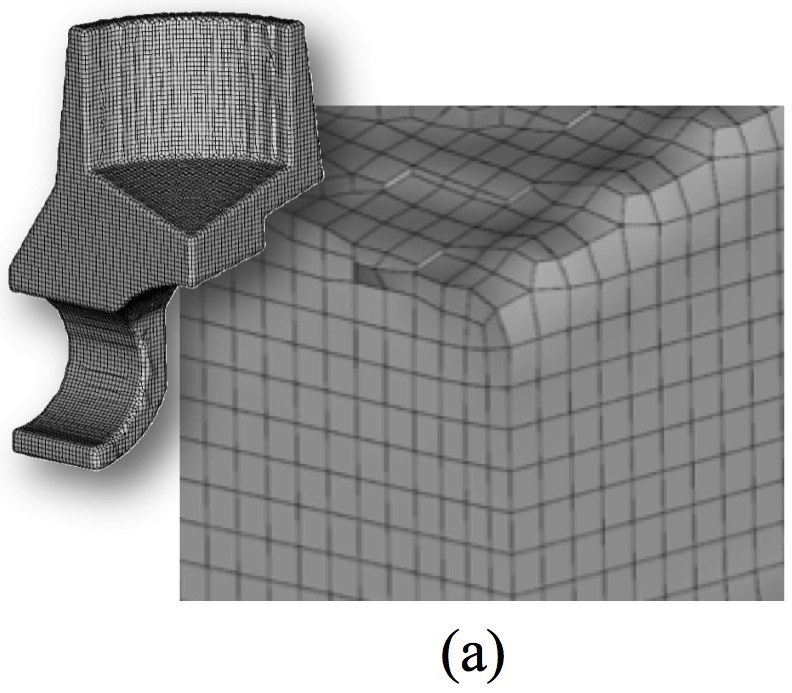

The model shown in the following figure was meshed using these three commands (part of the model is not shown to reveal the internal structure of the model).

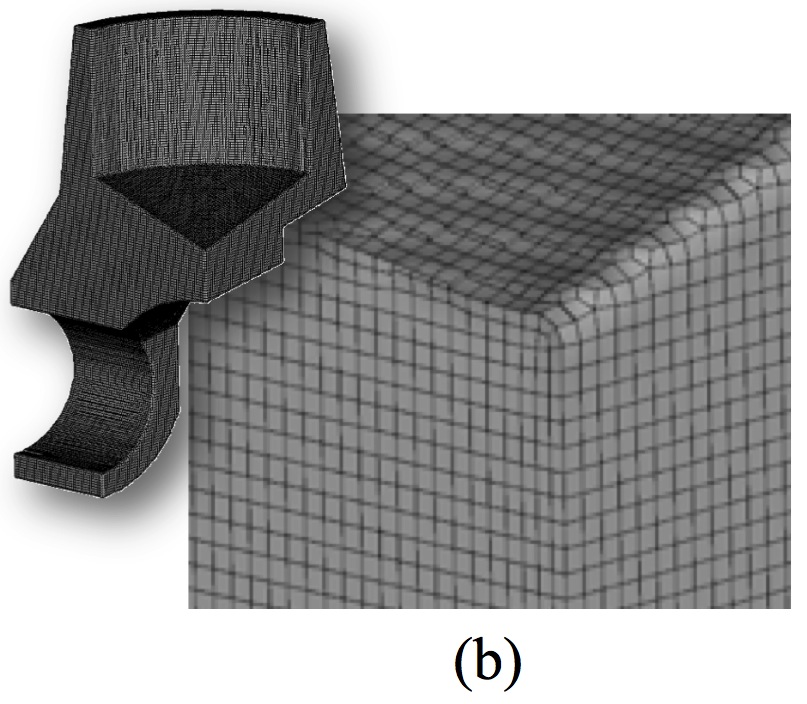

Figure 227: Non-trivial model meshed using automatic scheme selection

5.4.7.3 Scheme Firmness

Meshing schemes may be selected through three different approaches. They are: default settings, automatic scheme selection, and user specification. These methods also affect the scheme firmness settings for surfaces and volumes. Scheme firmness is completely analogous to interval firmness.

{geom_list} Scheme {Default | Soft | Hard}

Scheme firmness settings can only be applied to surfaces and volumes.

This may be useful if the user is working on several different areas in the model. Once she/he is satisfied with an area’s scheme selection and doesn’t want it to change, the firmness command can be given to hard set the schemes in that area. Or, if some surfaces were hard set by the user, and the user now wants to set them through automatic scheme selection then she/he may change the surface’s scheme firmness to soft or default.

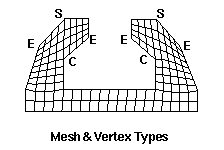

5.4.7.4 Surface Auto Scheme Selection

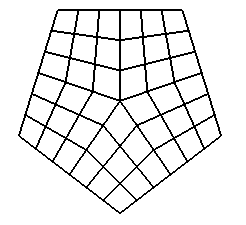

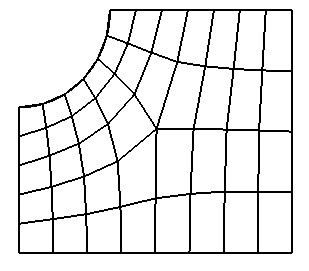

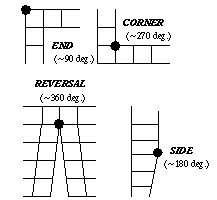

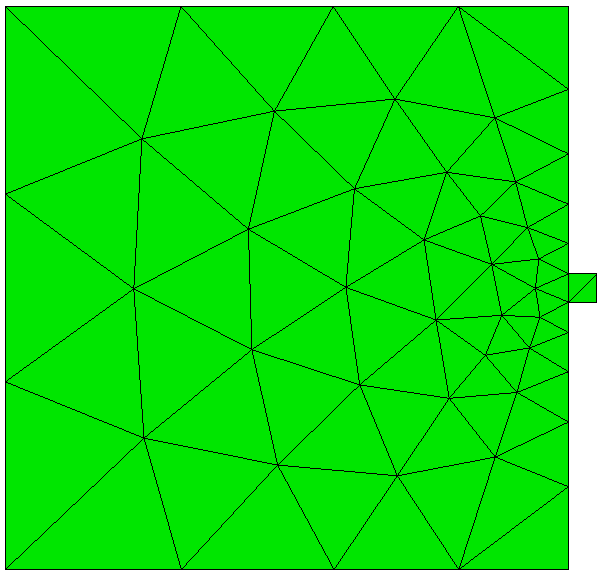

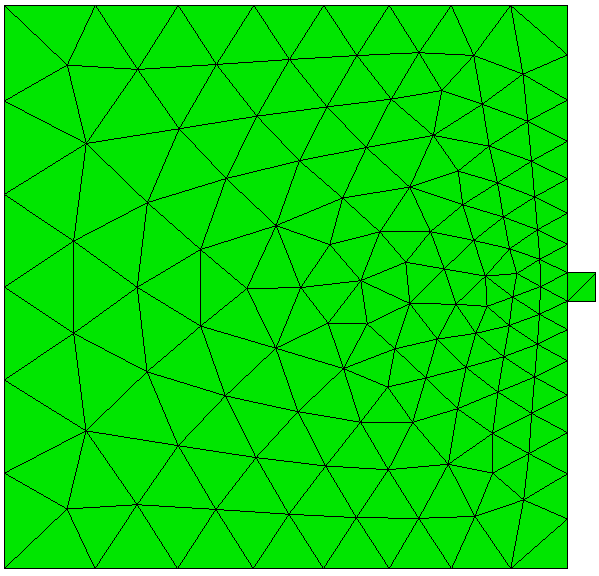

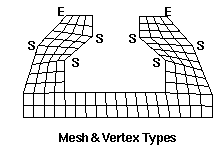

Surface auto scheme selection (White, 99) will choose between Pave, Submap, Triprimitive, and Map meshing schemes, and will always result in selecting a meshing scheme due to the existence of the paving algorithm, a general surface meshing tool (assuming the surface passes the even interval constraint).

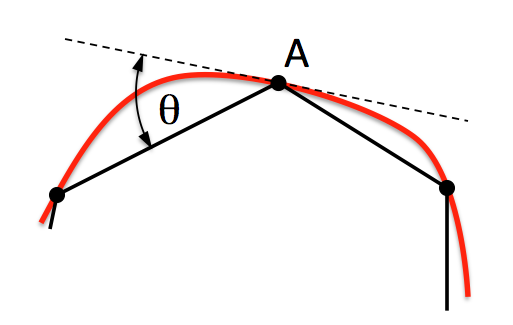

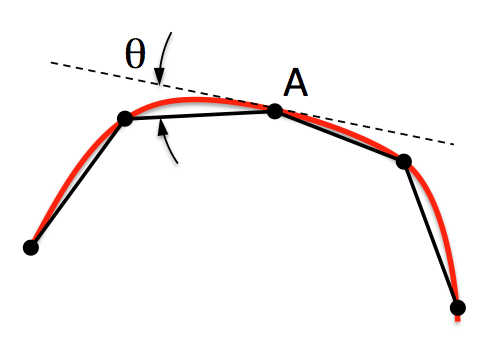

[Set] Scheme Auto Fuzzy [Tolerance] {value} (value in degrees)

5.4.7.5 Volume Auto Scheme Selection

When automatic scheme selection is called for a volume, surface scheme selection is invoked on the surfaces of the given volume. Mesh density selections should also be specified before automatic volume scheme selection is invoked due to the relationship of surface and volume scheme assignment.

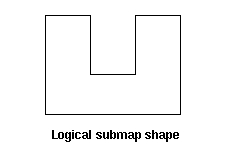

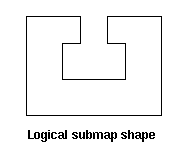

Volume scheme selection chooses between Map, Submap and Sweep meshing schemes. Other schemes can be assigned manually, either before or after the automatic scheme selection.

Volume scheme selection is limited to selecting schemes for 2.5D geometries, with additional tool limitations (e.g. Sweep can currently only sweep from several sources to a single target, not multiple targets); this is due to the lack of a completely automatic 3D hexahedral meshing algorithm. If volume scheme selection is unable to select a meshing scheme, the mesh scheme will remain as the default and a warning will be reported to the user.

Volume scheme selection can fail to select a meshing scheme for several reasons. First, the volume may not be mappable and not 2.5D; in this case, further decomposition of the model may be necessary. Second, volume scheme selection may fail due to improper surface scheme selection. Volume schemes such as Map, Submap, and Sweep require certain surface meshing schemes, as mentioned previously.

5.4.8 Conversion

5.4.8.1 HTet

Applies to: Volumes

Summary: Converts an existing hex mesh into a conforming tetrahedral mesh.

HTet Volume <range> {UNSTRUCTURED | structured}

Unlike other meshing schemes in this section, The HTet command requires an existing hexahedral mesh on which to operate. Rather than setting a meshing scheme for use with the mesh command, the HTet command works after an initial hex mesh has been generated.

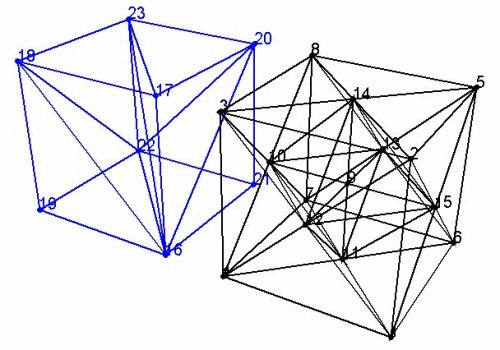

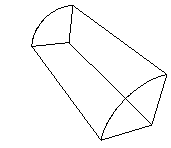

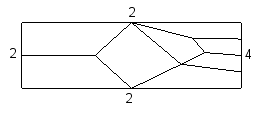

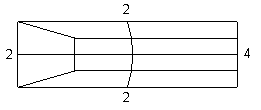

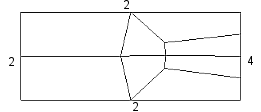

Two methods for decomposing a hex mesh into tetrahedra are available. Set the method to be used with the optional arguments unstructured and structured. The unstructured method is the default. Figure 228 shows the difference between the two methods:

Figure 228: Left: Unstructured method creates 6 tets per hex. Right: Structured method creates 28 tets per hex

5.4.8.1.1 Unstructured

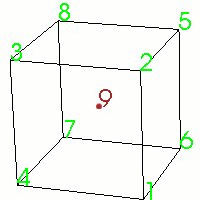

This method creates 6 tetrahedra for every hexahedra. No new nodes will be generated. The orientation of the 6 hexahedra will be based upon the element node numbering, as a result orientations may change if node numbering changes. This method is referred to as unstructured because the number of tetrahedra adjacent each node will be relatively arbitrary in the final mesh. Tetrahedral element quality is generally sufficient for most applications, however the user may want to verify quality before performing analysis.

5.4.8.1.2 Structured

With this approach, 28 tetrahedra are generated for every hexahedra in the mesh. This method adds a node to each face of the hex and one to the interior. Although this method generates significantly more elements, the orientation and quality of the resulting tetrahedra are more consistent. Each previously existing interior node in the mesh will have the same number of adjacent tetrahedra.

5.4.8.2 QTri

Applies to : Surfaces

Summary: Meshes surfaces using a quadrilateral scheme, then converts the quadrilateral elements into triangles.

Surface <range> Scheme Qtri [Base Scheme quad_scheme>]

QTri {Surface <range> | Face <range> }

Set QTri Split [2|4]

Set QTri Test {Angle|Diagonal}

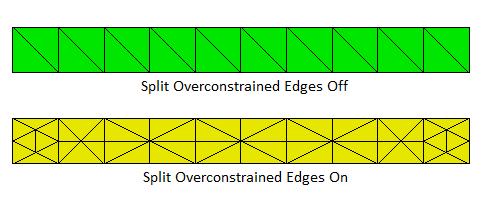

Discussion: QTri is used to mesh surfaces with triangular elements. The surface is, first, meshed with the quadrilateral scheme, and, then, the generated quads are split along a diagonal to produce triangles. The first command listed above sets the meshing scheme on a surface to QTri. The second form sets the scheme and generates the mesh in a single step.

In the first command, the user has the option of specifying the underlying quadrilateral meshing scheme using the base scheme <quad_scheme> option. If no base scheme is specified, Cubit will automatically select a scheme. For non-periodic surfaces, the base scheme will be set to scheme pave. For periodic surfaces, the base scheme will be set to scheme map.

Generally, the second command, Qtri Surface <range>, is used on surfaces that have already been meshed with quadrilaterals. If, however, this command is used on a surface that has not been meshed, a base scheme will automatically be selected using CUBIT’s auto-scheme capabilities. The user can over-ride this selection by specifying a quadrilateral meshing scheme prior to using the qtri command (using the Surface <range> Scheme <quad_scheme> command). QTri may also be performed on quadrilateral elements on a surface or a subset of quadrilateral elements on a surface. to split existing quadrilaterals the QTri command can be given a list of faces.

In addition to the default 2 tris per quad, the set qtri split command may alter the QTri scheme so that it will split the quad into 4 triangles per quad. Where the 4 option is used, an additional mesh node is placed at the centroid of each quad.

There are two methods that may be used to calculate the best diagonal to use for splitting the quadrilateral elements: angle or diagonal. The angle measurement uses the largest angle, while the diagonal option uses the shortest diagonal. The largest angle measurement will be more accurate but takes more time.

Also, the QTri scheme is used in the TriMesh command as a backup to the TriAdvance triangle meshing scheme.

5.4.8.3 THex

Applies to: Volumes

Summary: Converts a tetrahedral mesh into a hexahedral mesh.

THex Volume <range>

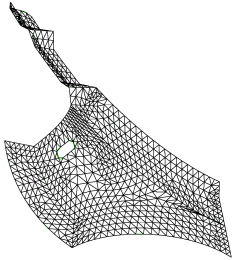

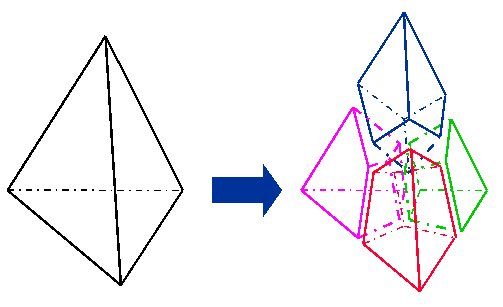

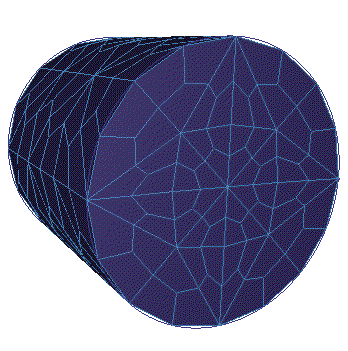

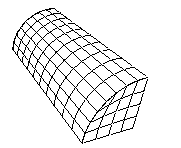

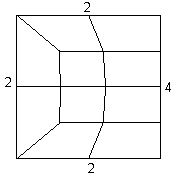

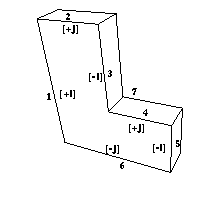

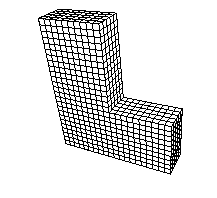

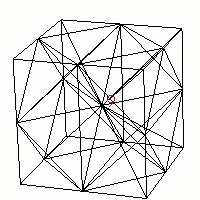

Discussion: The THex command splits each tetrahedral element in a volume into four hexahedral elements, as shown in Figure 230. This is done by splitting each edge and face at its midpoint, and then forming connections to the center of the tet.

When THexing merged volumes, all of the volumes must be THexed at the same time, in a single command. Otherwise, meshes on shared surfaces will be invalid. An example of the THex algorithm is shown in Figure 231.

Figure 230: Conversion of a tetrahedron to four hexahedra, as performed by the THex algorithm.

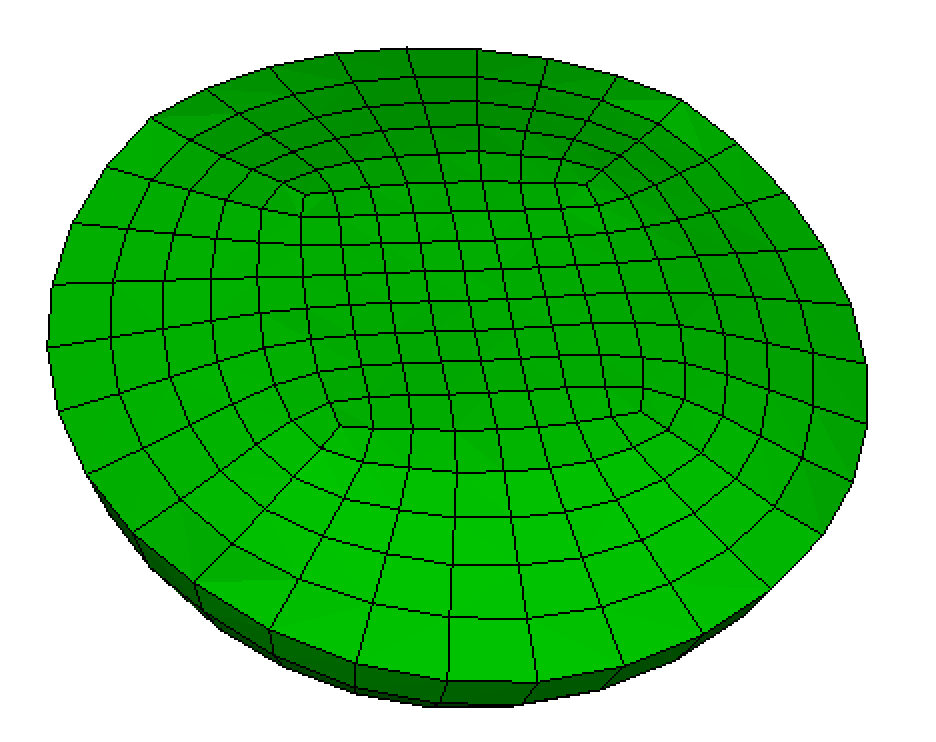

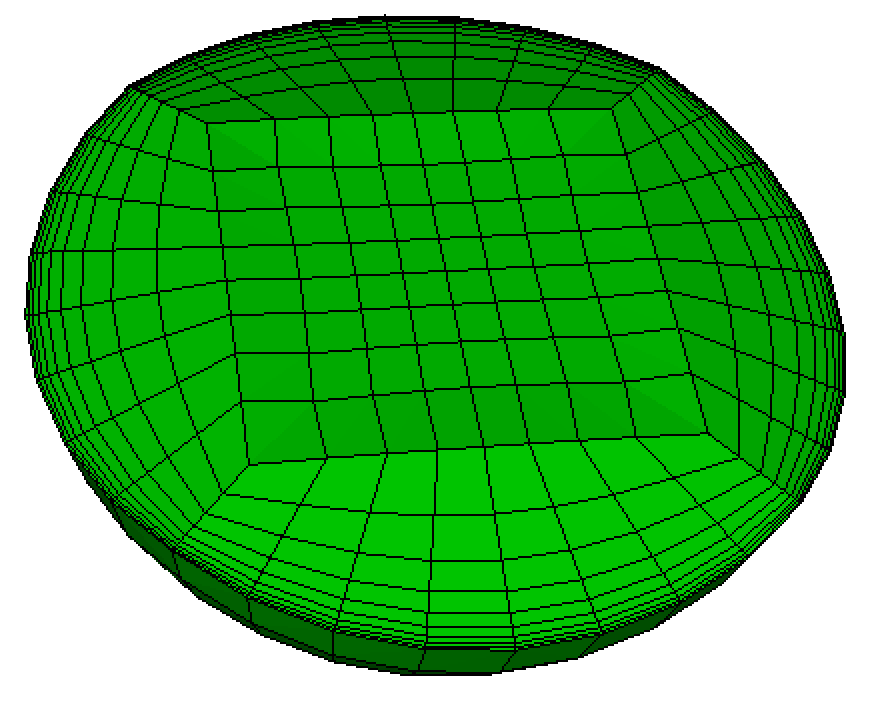

Figure 231: A cylinder before and after the THex algorithm is applied.

5.4.8.4 TQuad

Applies to: Surfaces

Summary: Converts a triangular surface mesh into a quadrilateral mesh.

TQuad Surface <range>

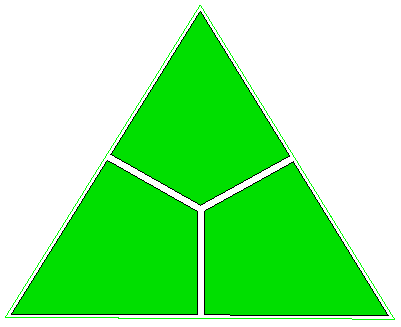

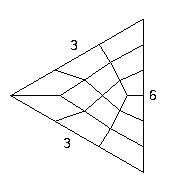

Discussion: The TQuad command splits each triangular surface element in four quadrilateral elements, as shown in Figure 232. This is done by splitting each edge at its midpoint, and then forming connections to the center of the triangle. The result is the same as using the THex algorithm, but only applies to surfaces. In general it is better to use a mapped or paved mesh to generate quadrilateral surface meshes. However, the TQuad scheme may be useful for converting facet-based triangular meshes to quadrilateral meshes when remeshing is not possible.

Figure 232: A triangle split into 3 quads using the TQuad scheme

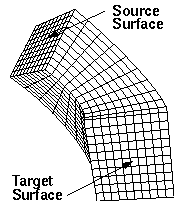

5.4.9 Copying a Mesh

Applies to: Curves, Surfaces, Volumes

Summary: Copies the mesh from one entity to another

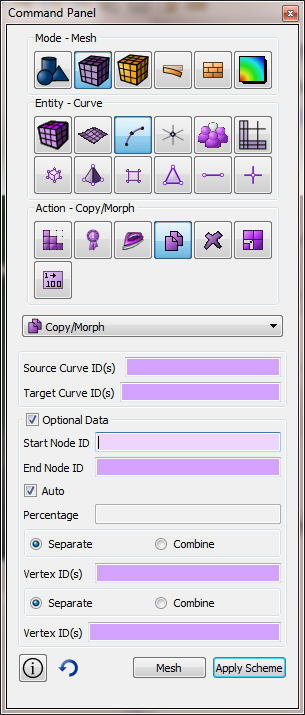

To copy a mesh on a curve

On the Command Panel, click on Mesh and then Curve.

Click on the Copy/Morph action button.

Enter the values for Source Curve ID(s) and Target Curve ID(s). This can also be done using the Pick Widget function.

Optionally, click on Optional Data to further specify the settings.

Click on Appy Scheme and then Mesh.

The Command Panel GUI is shown below:

Curve <range> Scheme Copy source Curve <range> [Source Percent [<percentage> | auto]] [Source [combine|SEPARATE]] [Target [combine|SEPARATE]] [Source Vertex <id_range>] [Target Vertex <id_range>]]

Copy Mesh Curve <curve_id> Onto Curve <curve_id_range> [Source Node <starting node id> <ending node id>] [Source Percent [<percentage>|auto]] [Source Vertex <id_range>] [Target Vertex <id_range>]

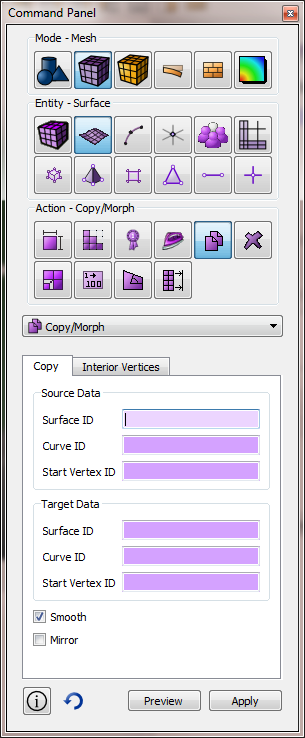

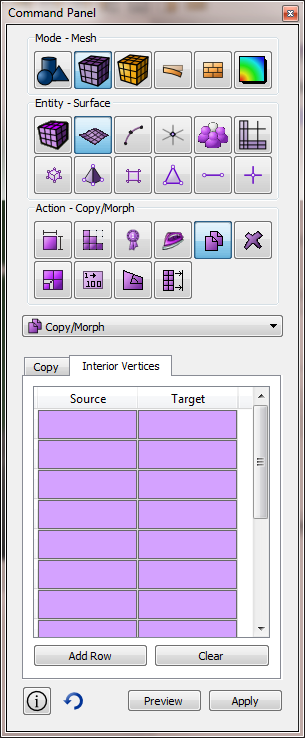

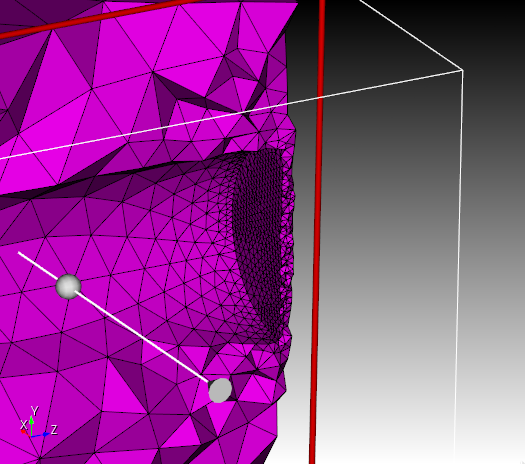

To copy a mesh on a surface

On the Command Panel, click on Mesh and then Surface.

Click on the Copy/Morph action button.

Using the pickwidgets in the command panel select source and target data.

To force copying of interior vertex loops select the "Interior Vertices" tab and enter in pairs of vertices to be matched when copying.

The Command Panel GUI is shown below:

Copy Mesh Surface <surface_id> Onto Surface <surface_id> Source Curve<id> Target Curve <id> Source Vertex <id>Target Vertex <id> [Interior (pair vertex <id><id>)...] [smooth] [mirror] [preview]

Surface <id> Scheme copy source surface <id> source curve <id> target curve <id> source vertex <id> target vertex <id> [nosmoothing][mirror]

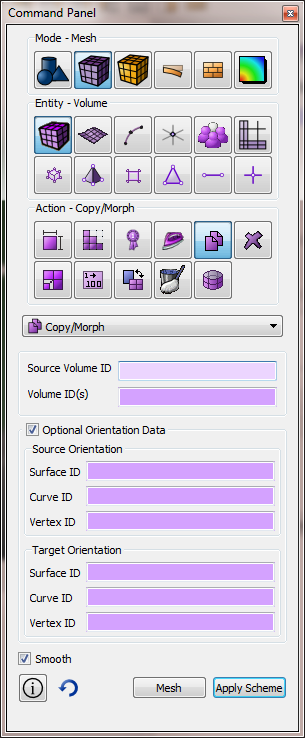

To copy a mesh on a volume

On the Command Panel, click on Mesh and then Volume.

Click on the Copy/Morph action button.

Enter the values for Source Volume ID(s) and Target Volume ID(s). This can also be done using the Pick Widget function.

Optionally, click on Optional Data to further specify the settings.

Click on Appy Scheme and then Mesh.

The Command Panel GUI is shown below:

Volume <range> Scheme Copy [Source Volume] <id> [[Source Surface <id> Target Surface <id>] [Source Curve <id> Target Curve <id>] [Source Vertex <id> Target Vertex <id>]][Nosmoothing]

Copy Mesh Volume <volume_id> Onto Volume <volume_id> [Source Vertex <vertex_id> Target Vertex <vertex_id>] [Source Curve <curve_id> Target Curve <curve_id>] [Nosmoothing]

Set Morph Smooth {on | off}

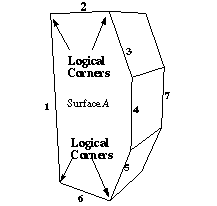

Discussion: If the user desires to copy the mesh from a surface, volume, curve, or set of curves that has already been meshed, the copy mesh scheme can be used. Note that this scheme can be set before the source entity has been meshed; the source entity will be meshed automatically, if necessary, before the mesh is copied to the target entity. The user has the option of providing orientation data to specify how to orient the source mesh on the target entity. For example, when copying a curve mesh, the user can specify which vertex on the source (the source vertex) gets copied to which vertex on the target (the target vertex). If you need to reference mesh entities for the copy, use the copy mesh commands. If no orientation data is specified, or if the data is insufficient to completely determine the orientation on the target entity, the copy algorithm will attempt to determine the remaining orientation data automatically. If conflicting, or inappropriate, orientation data is given, the algorithm attempts to discard enough information to arrive at a proper mesh orientation.

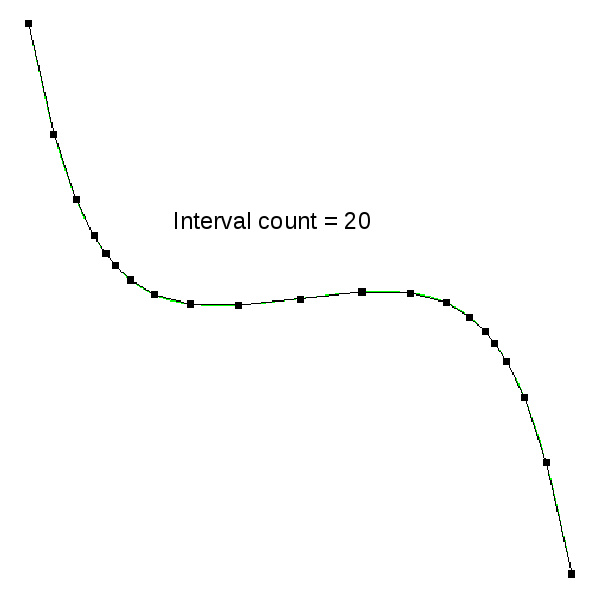

Curve mesh copying has certain options that allow the copying of just a section of the source curves’ mesh. These options are accessed through the extra keyword options. The percent option allows the user to specify that a certain percentage of the source mesh be copied–in this context the auto keyword means that the percentage will be calculated based on the ratio of lengths of the source and target curves. The combine and separate keywords relate to how the command line options are interpreted. If the user wishes to specify a group of target curves that will each receive an identical copy of a source mesh, then the target separate option should be used (this is the default). If, however, the user wishes the source mesh to be spread out along the range of target curves, then the target combine option should be used. The source curves are treated in a similar fashion.

Surface mesh copying with multiple holes in the surface may require matching up interior pair vertices. This will be required if the algorithm cannot match them up spatially. Interior pair vertices can be specified with the option interior pair vertex ...

Volume mesh copying depends on the surface copying scheme. Because of this, the target volume must not have any of its surfaces meshed already.

copy mesh surf 23 onto surf 14 source curve 1 source vertex 1 target curve 24 target vertex 20

5.4.10 Radialmesh

Creates a free cylindrical mesh with precise node locations based on input radii, angles, and offsets, then creates mesh-based geometry to fit the mesh.

Create Radialmesh \

NumZ <val> [Span <val>] \

Zblock 1 [<offset val>] \

{Interval|Bias|Fraction|First Size} <val> \

[{Interval|Bias|Fraction|Last Size} <val>] \

Zblock 2 [<offset val>] \

{Interval|Bias|Fraction|First Size} <val> \

[{Interval|Bias|Fraction|Last Size} <val>] \

... NumZ \

NumR <val> {Trisection|Initial Radius<val>} \

Rblock 1 <offset radius val> \

{Interval|Bias|Fraction|First Size} <val> \

[{Interval|Bias|Fraction|Last Size} <val>] \

Rblock 2 <offset radius val> \

{Interval|Bias|Fraction|First Size} <val> \

[{Interval|Bias|Fraction|Last Size} <val>] \

... NumR \

NumA <val> [Full360] [Span <val>] \

Ablock 1 [<offset angle val>] \

{Interval|Bias|Fraction|First Angle} <val> \

[{Interval|Bias|Fraction|Last Angle} <val>] \

Ablock 2 [<offset angle val>] \

{Interval|Bias|Fraction|First Angle} <val> \

[{Interval|Bias|Fraction|Last Angle} <val>] \

... NumA

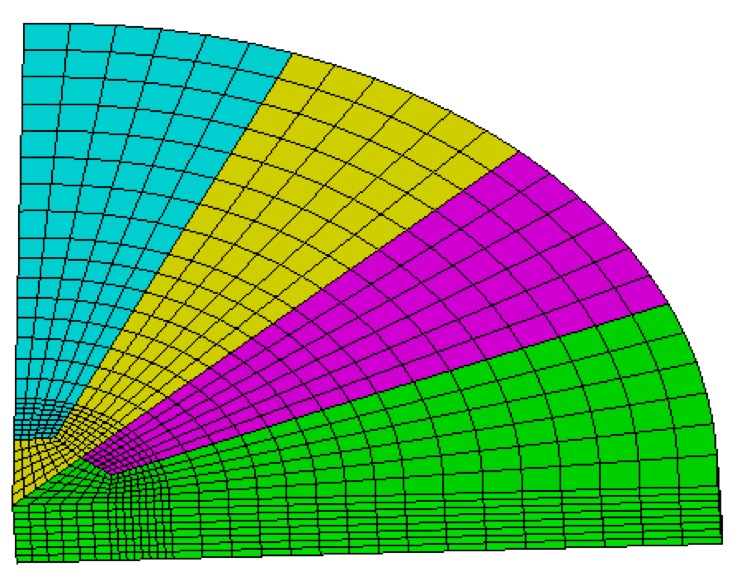

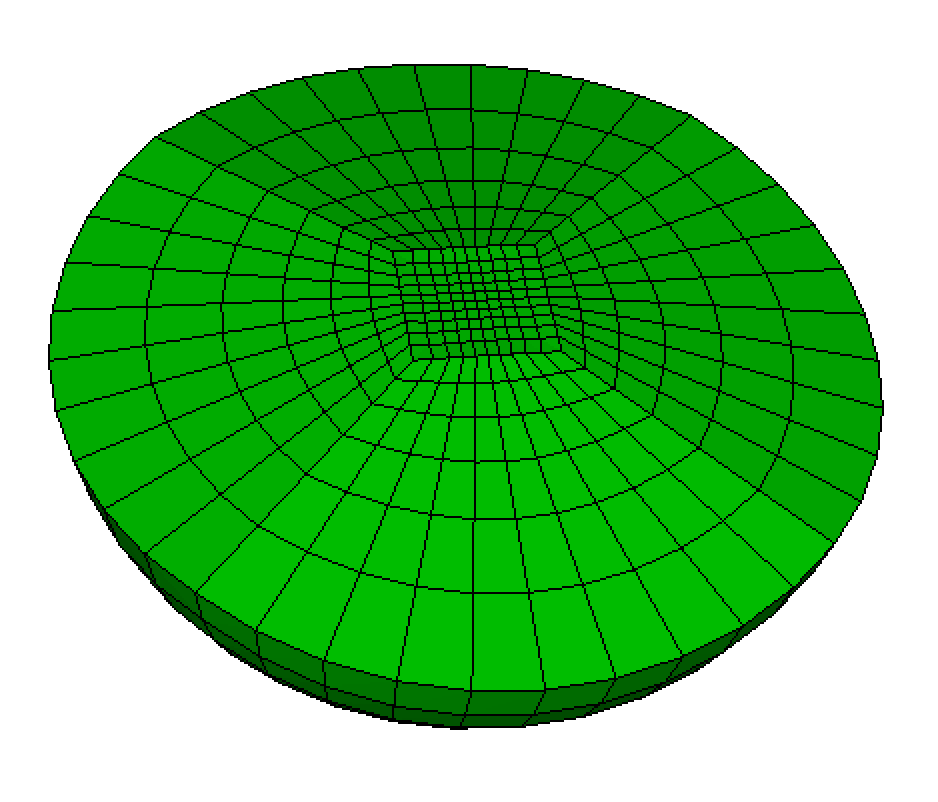

The purpose of the radialmesh command is to create a cylindrical mesh with precise node locations. Unlike all other meshing commands which place nodes using smoothing algorithms to optimize element quality, node locations for the radialmesh command are calculated based on the input radii, angles, and offsets. In addition, the radialmesh command does not mesh existing geometry. Rather, it creates a mesh based on the input parameters, after which a mesh-based geometry is created to fit the free mesh.

The radialmesh command requires input for the 3 coordinate directions (Z, radial, angular). The number of blocks in each direction is specified with the numZ, numR, and numA values in the command. Each block forms a new volume in the final mesh. All bodies in the mesh are merged to form a conformal mesh between blocks.

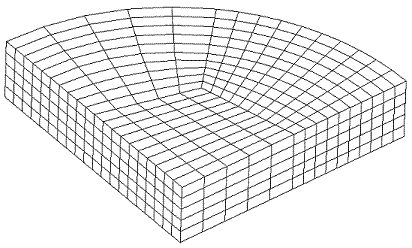

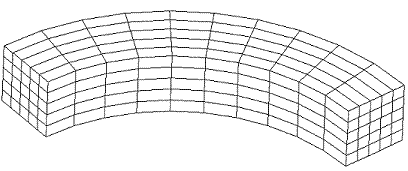

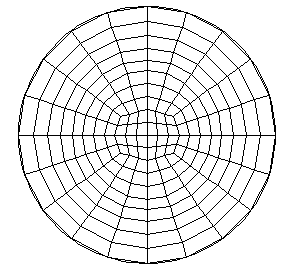

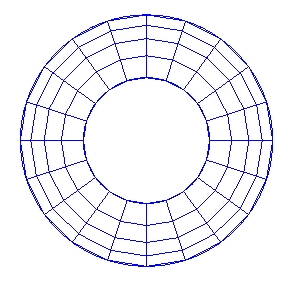

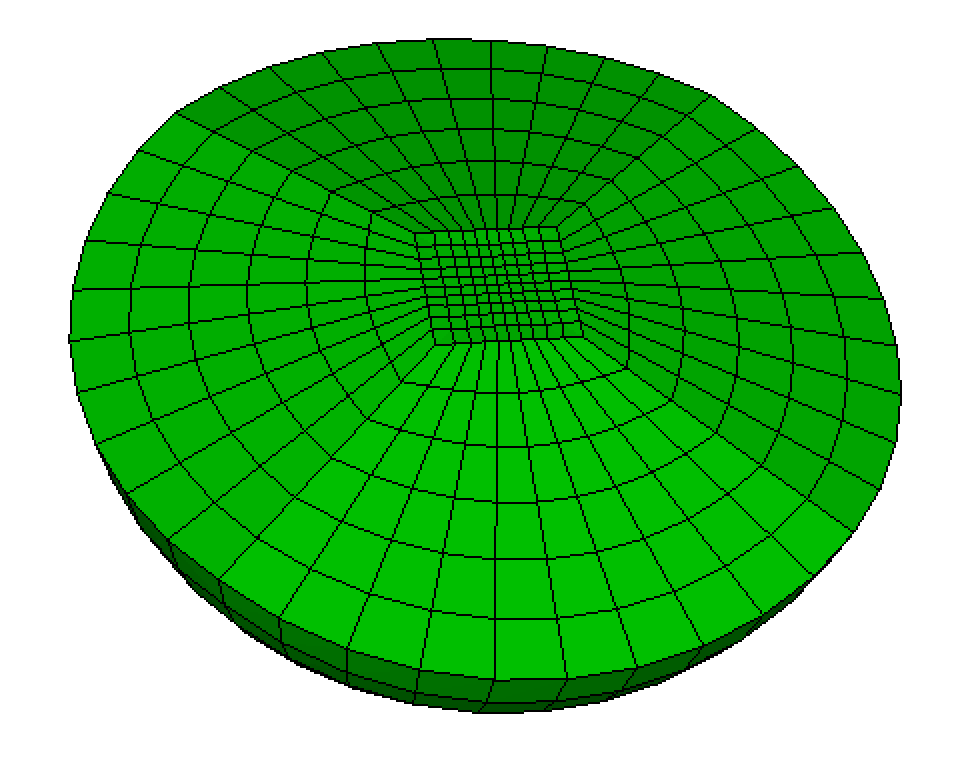

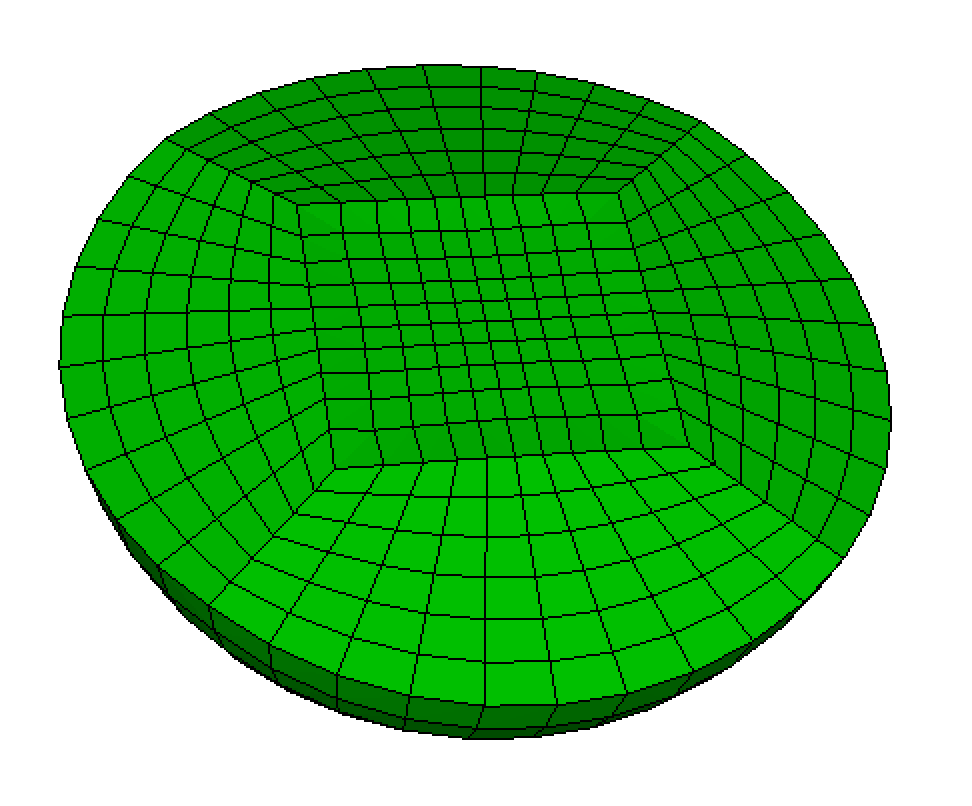

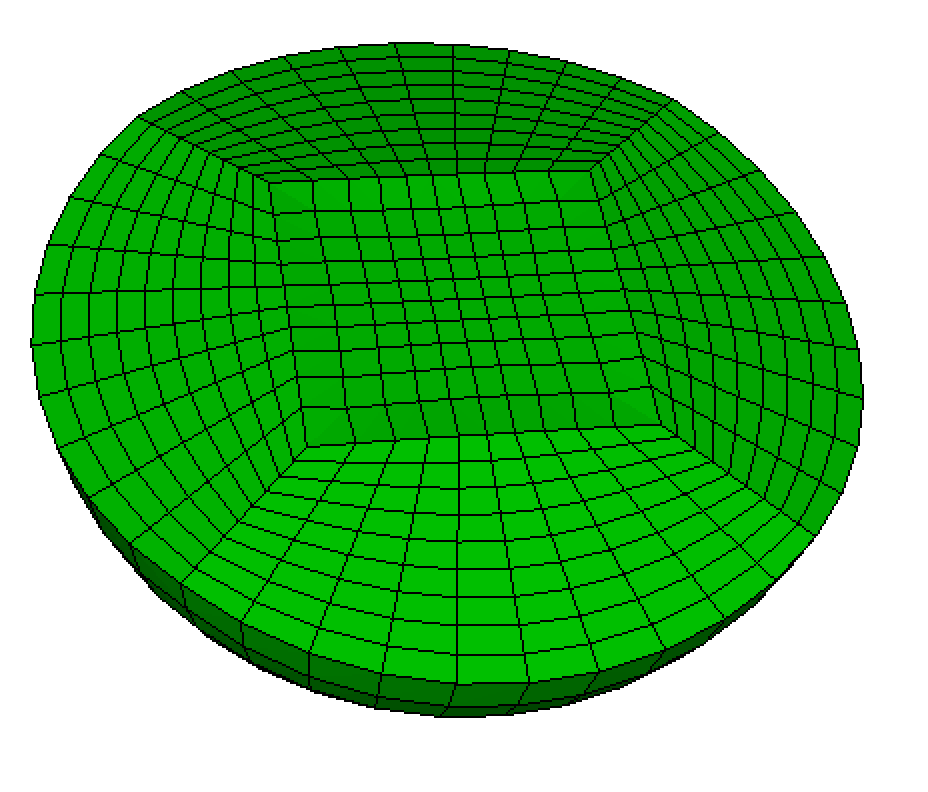

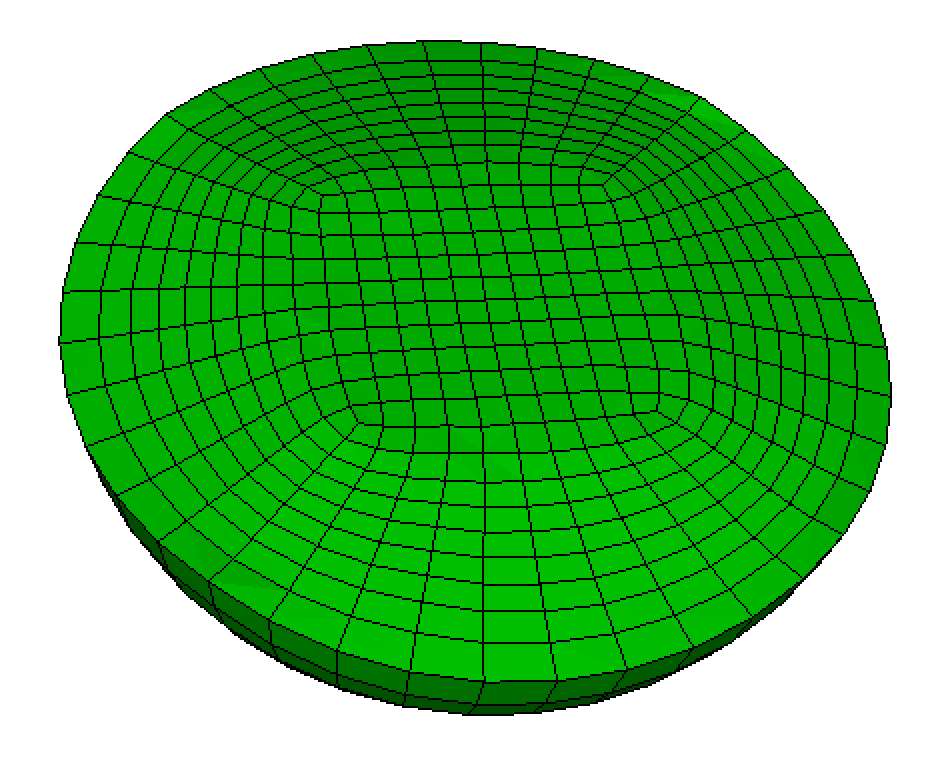

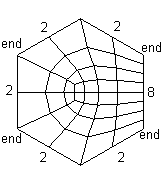

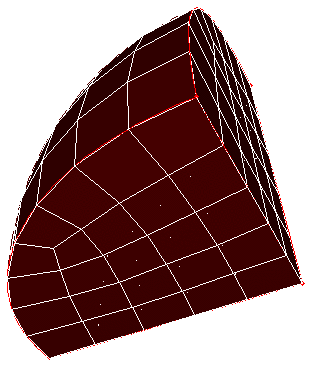

The Radialmesh command can create meshes which span any angle greater than 0.0 up to 360 degrees. In addition, meshes can model either a tri-section (see Figure 237), or a non-trisection mesh (see Figure 238).

create radialmesh \

numZ 1 zblock 1 1 interval 5 \

numR 3 trisection rblock 1 2 interval 5 \

rblock 2 3 interval 5 \

rblock 3 4 interval 5 \

numA 1 span 90 ablock 1 interval 10

The command to generate the mesh in Figure 238 is:

create radialmesh \

numZ 1 zblock 1 1 interval 5 \

numR 1 initial radius 3 rblock 1 4 interval 5 \

numA 1 span 90 ablock 1 interval 10

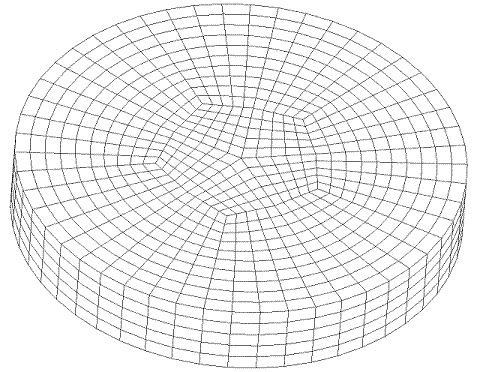

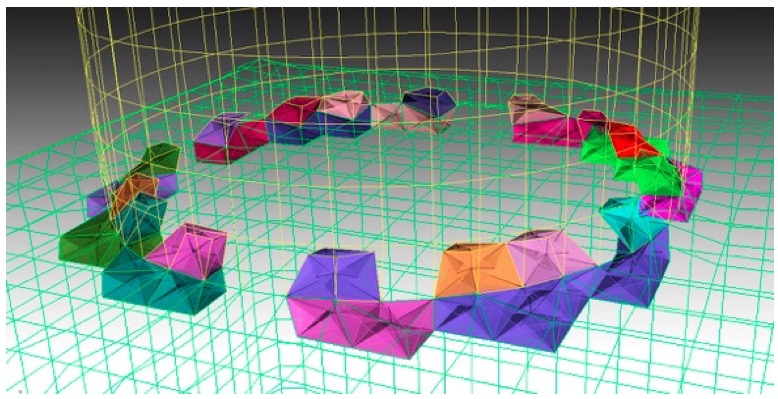

A mesh can span an entire 360 degrees by using the "full360" keyword. For example, the mesh in Figure 3 was generated with the following command:

create radialmesh numZ 1 zblock 1 1 interval 5 \

numR 3 trisection rblock 1 1 interval 5 \

rblock 2 2 interval 5 \

rblock 3 3 interval 5 \

numA 5 full360 span ablock 1 interval 5 \

ablock 2 interval 5 \

ablock 3 interval 5 \

ablock 4 interval 5

The user can control the number of intervals and the spacing of these intervals using the optional parameters in each rblock, zblock and ablock. There are 11 combinations that these can be combined as listed below:

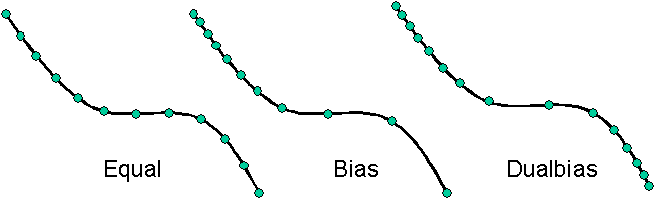

Interval Only- Example: "interval 5." The block will be meshed with 5 equally spaced intervals.

First Size Only- Example: "first size 2.5." The block will be meshed with intervals of approximately 2.5 in length. The total number of intervals is internally calculated and depends on the overall block length.

Fraction Only- Example: "fraction 0.3333." The block will be meshed with intervals approximately 0.3333*overall block length.

Interval and Bias- Example: "interval 5 bias 1.5." There will be 5 intervals on the block, which each interval being 1.5 times the previous one. The length of each interval is calculated internally.

Interval and Fraction- Example: "interval 5 fraction 0.25." There will be 5 intervals on the block, the first being .25 of the length of the block with the remaining decreasing in size.

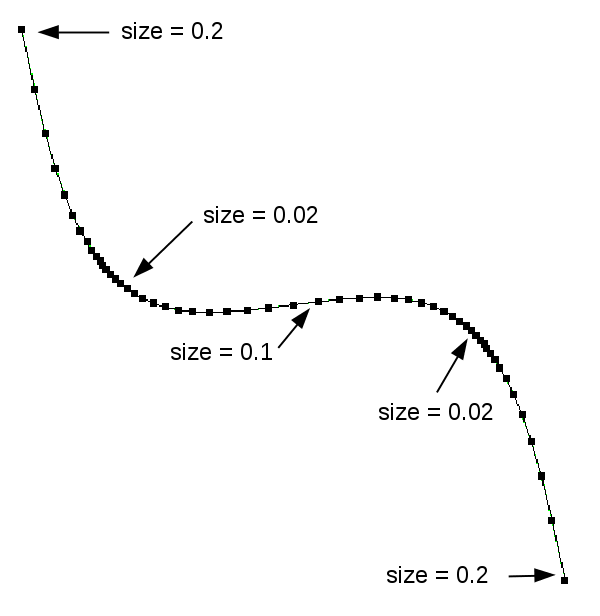

Interval and First Size- Example: "interval 5 first size 0.2." There will be 5 intervals on the block, the first being 0.2 in length. The remaining intervals will increase or decrease to fill the blocks length.

First Size and Last Size- Example: "first size 0.2 last size 0.4." The first interval will be 0.2 in length. The last interval will be 0.4 in length. The total number of intervals is internally calculated to allow for transition between the 2 specified sizes.

First Size and Bias- Example "first size 0.2 bias 0.85." The first interval will be 0.2 in length and the remaining intervals will scale by a factor of 0.85 from one to the next until the block is filled. The total number of intervals is internally calculated and depends on the overall block length.

Fraction and Bias- Example "fraction 0.25 bias 1.25." The first interval will be 0.25 of the overall block length and the remaining intervals will scale by a factor of 1.25 from one to the next until the block is filled. The total number of intervals is internally calculated and depends on the overall block length.

Interval and Last Size- Example: "last size 1.5 interval 5." The last interval will be 1.5 in length. The remaining intervals will scale up or down to fit 5 intervals in the block.

Last Size and Bias- Example: "last size 2.0 bias 1.1." The last interval will be 2.0 in length. The remaining intervals will scale by 1.1 until the block is filled. The total number of intervals is internally calculated and depends on the overall block length.

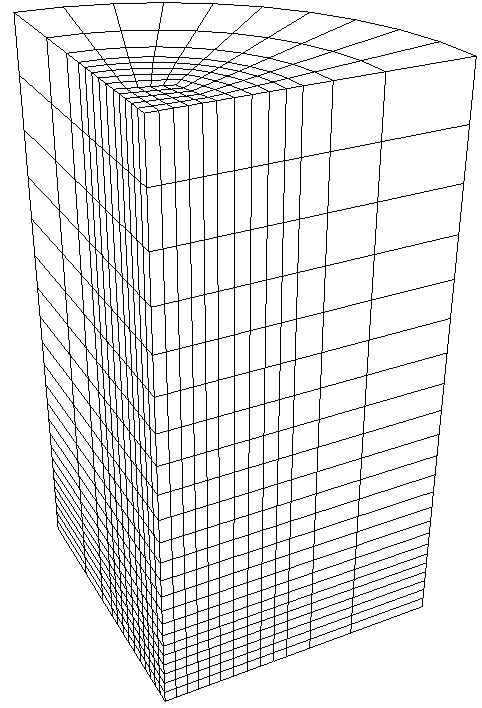

Figure 240 shows an example of a bias spaced mesh with the following command:

create radialmesh numZ 2 zblock 1 1 first size 0.2 \

zblock 2 10 first size 0.2 last size 1.0 \

numR 3 trisection rblock 1 1 interval 5 \

rblock 2 2 first size .25 \

rblock 3 5 first size .25 bias 2.0 \

numA 1 span 90 ablock 1 interval 5

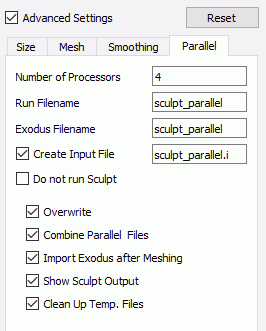

5.4.11 Parallel Meshing

Cubit has been designed as a serial application, using a single CPU to generate its meshes. In some cases, where memory or time constraints are critical, parallel meshing may be necessary. Cubit currently provides a separate application designed to run in parallel either on a desktop or on massively parallel cluster machines. In these cases, Cubit can be used as a pre-processor to manipulate geometry and set up for meshing, however the actual meshing procedure is performed as a separate process or on another machine.

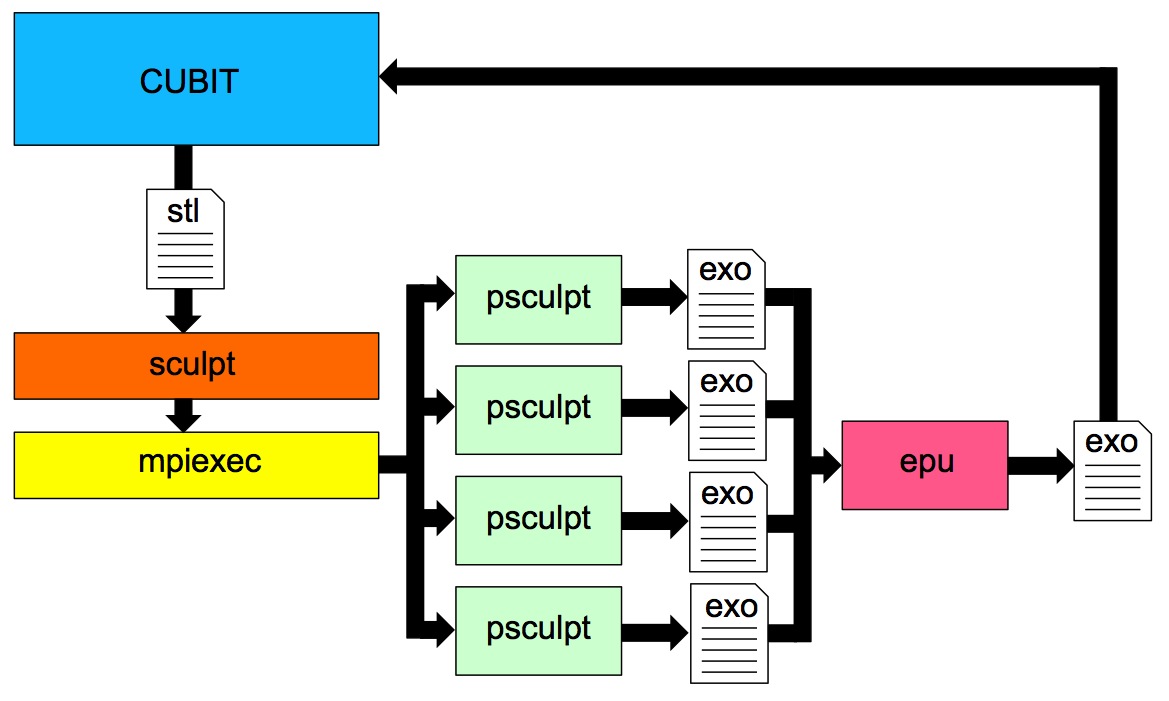

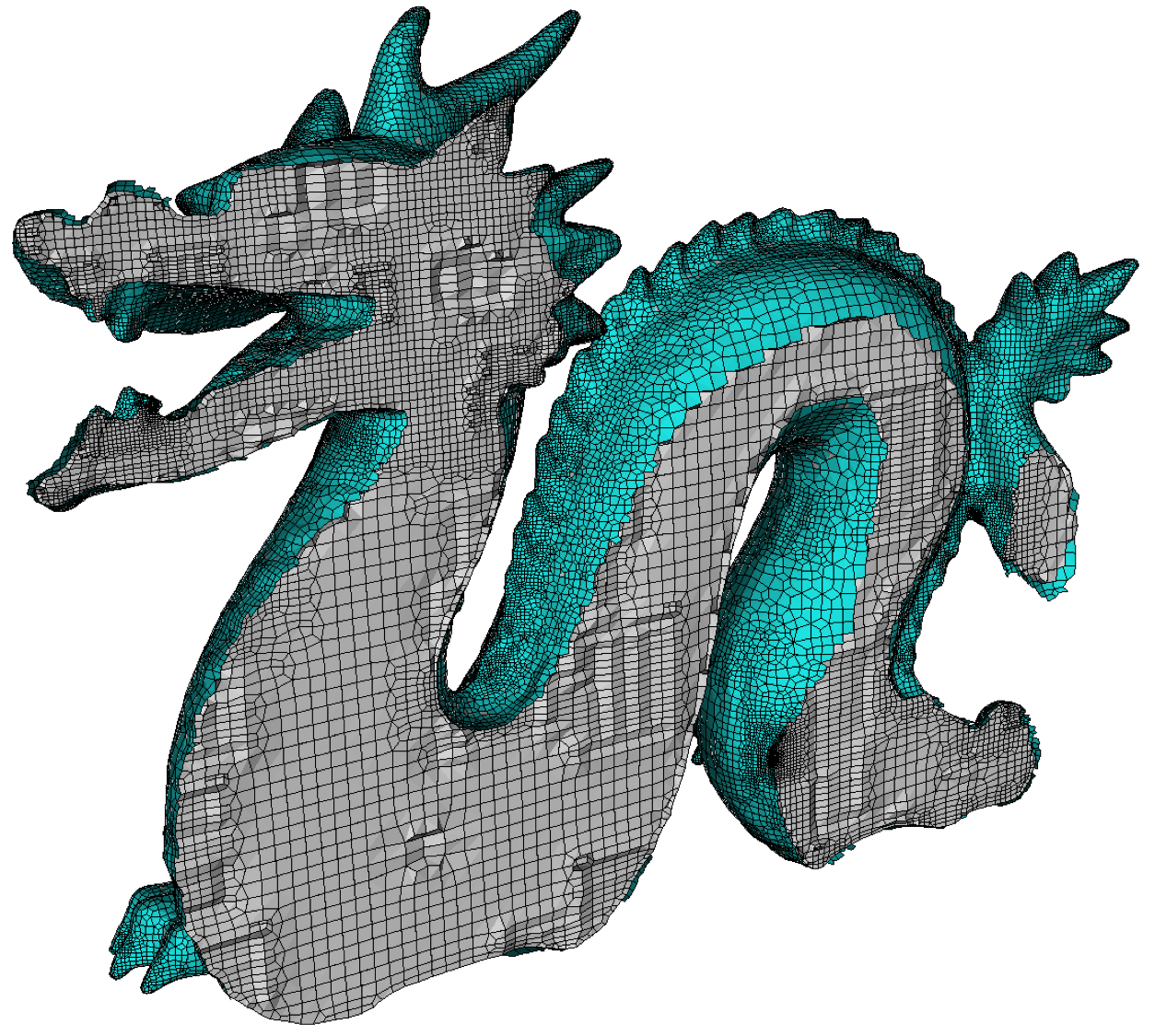

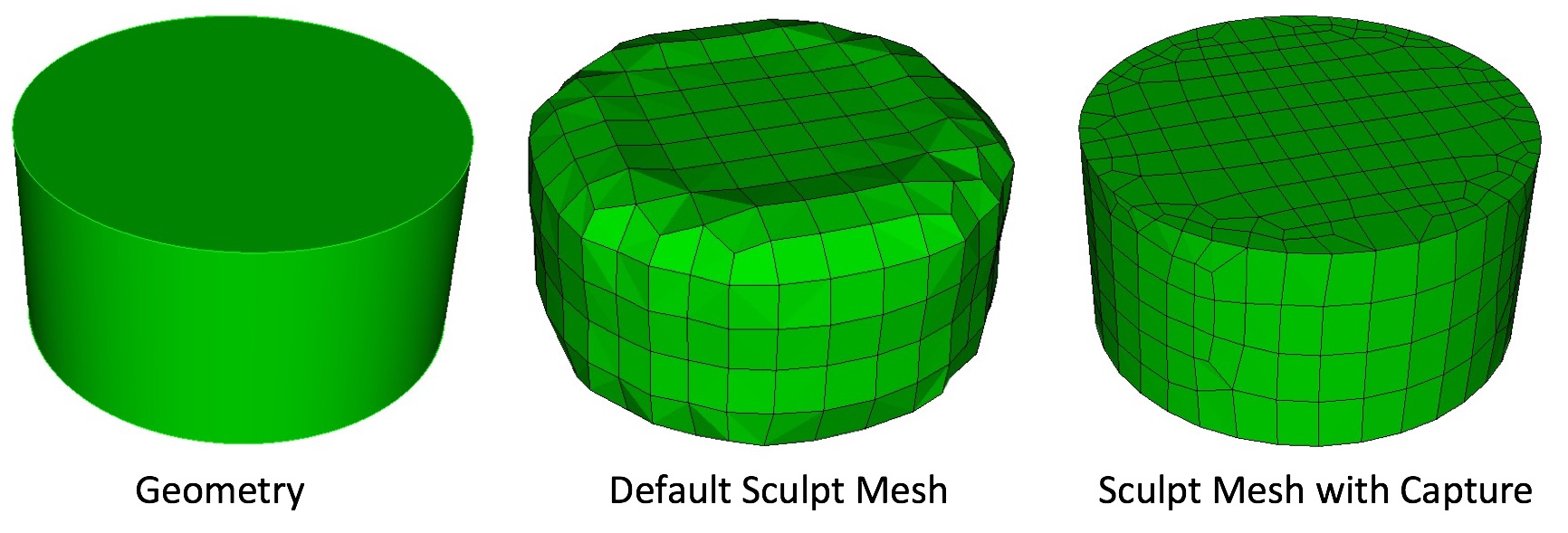

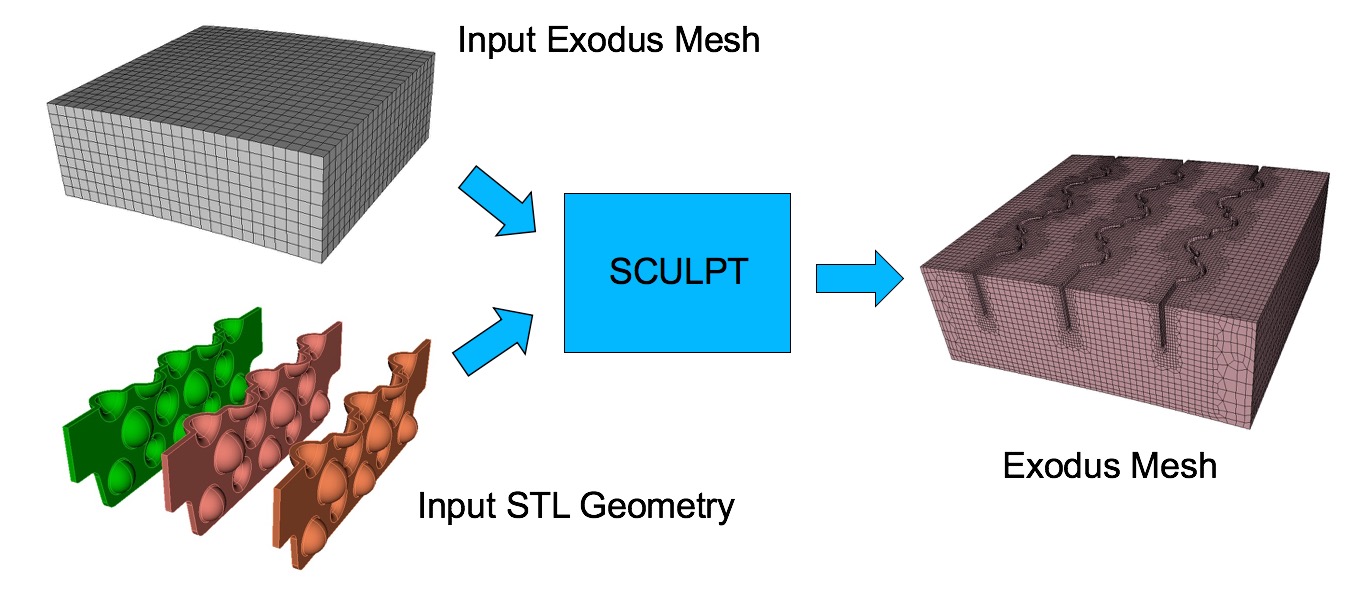

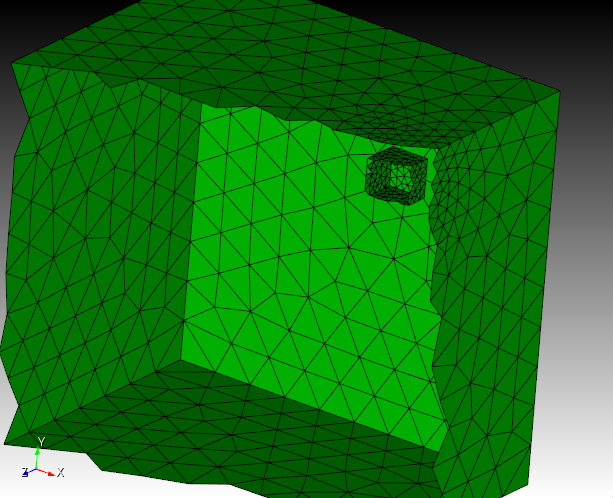

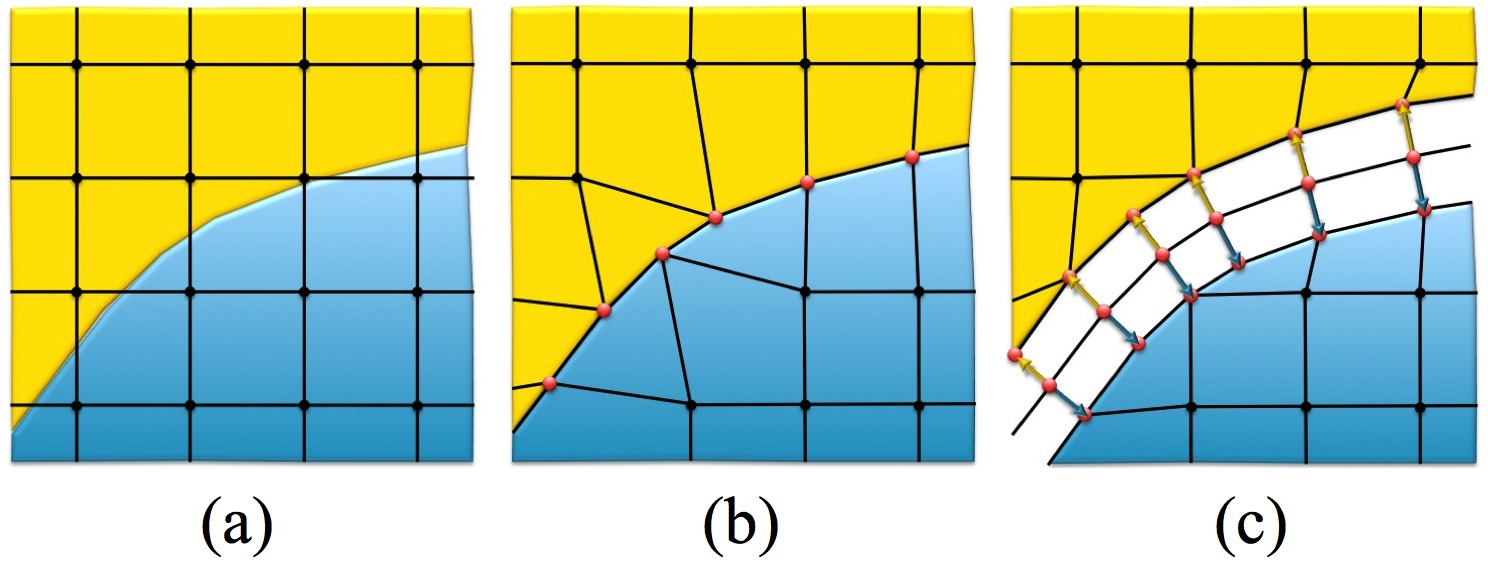

5.4.11.1 Sculpt

Sculpt is a separate parallel application designed to generate all-hex meshes on complex geometries with little or no user interaction. Sculpt was developed as a separate application so that it can be run independently from Cubit on high performance computing platforms. It was also designed as a separable software library so it can be easily integrated as an in-situ meshing solution within other codes. Cubit provides a front end command line and GUI for the Sculpt application. The command will build the appropriate input files based on the current geometry and can also automatically invoke Sculpt to generate the mesh and bring the mesh back to Cubit.

5.4.11.1.1 Preparing to Use Sculpt

5.4.11.1.1.1 Platforms

Sculpt is available for Windows, Mac and Linux operating systems.

5.4.11.1.1.2 Sculpt Installation

Sculpt is a stand-alone executable, separate from Cubit. In order for Cubit to start up Sculpt, it must be on your system and accessible to Cubit. The default installation of Cubit should install files in the correct locations for this to occur. Check with Cubit support if it did not come with your installation or you are not able to locate it or any of its supporting applications.

To run Sculpt from Cubit, four executable files are needed:

sculpt: Application that controls start-up of mpiexec and psculpt. Main entry point from Cubit, that checks for the existence and compatibility of either the system mpiexec application or will use a local cubit instalation of mpiexec.

psculpt: The main mpi-based Sculpt application. Requires mpiexec to run.

mpiexec: Standard application available on most linux-based operating systems for starting up mpi-based applications on multiple processors. This should be available with your Cubit installation, but is also available from http://open-mpi.org

epu: Used for combining multiple exodus files, generated with Sculpt, into a single exodus file. This executable is optional, but is useful for importing the resulting mesh into Cubit for viewing. It is part of the SEACAS tool suite developed by Sandia National Laboratories and is also included with your Cubit installation. It can also be obtained in open source form from https://github.com/gsjaardema/seacas.

Sculpt Parallel Path List |

See the Sculpt Parallel Path Command for more info on setting and customizing these paths.

The following image illustrates the process flow when the sculpt parallel command is used in Cubit.

5.4.11.1.1.3 Sculpt Process Flow

For the Sculpt meshing process, a set of files, including a facet-based stl file are written to disk. The sculpt application is then started up which in turn invokes mpiexec to start up multiple instances of psculpt in parallel. psculpt then performs the meshing and writes one exodus file per processor. These files can then be combined using epu and then imported back into Cubit for viewing.

5.4.11.1.1.4 Setting your Working Directory

When using the Sculpt Parallel command in Cubit, several temporary files will be written to the current working directory. Because of this, it is important to set your working directory before using Sculpt to a desired location where you want these files placed.

5.4.11.1.2 Sculpt Parallel Command

The command syntax for preparing a model for Sculpt is:

Sculpt Parallel |

|

|

[size <value>|autosize <value>] |

The following table is a summary of options that can be invoked from the Cubit sculpt parallel command. It includes an abbreviated description of the option as well as the option’s default. If the option is not explicitly used in the command, the default value listed will be used. The Sculpt option is the corresponding command that can be used in a sculpt input file when sculpt is invoked directly from a terminal window. See Sculpt Application for more information.

Cubit Option |

| Description |

| Default |

| Sculpt Option |

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

|

5.4.11.1.3 Controlling the Execution of Sculpt

The following command options can be used to control the execution of Sculpt from within Cubit and can be used with the sculpt parallel command. Follow the links above for others not lsted here.

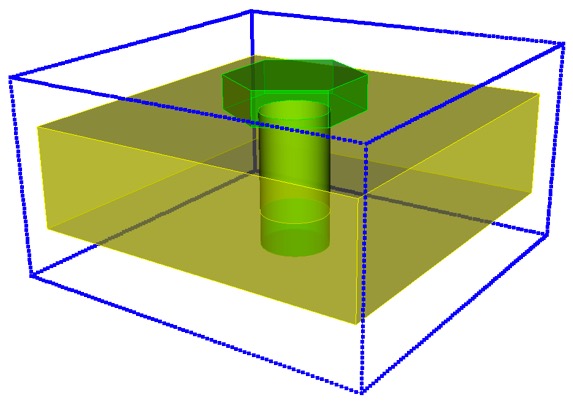

volume <ids> | block <ids> List of volumes or blocks to include in the mesh. One file containing a faceted representation (STL) per volume will be generated and saved in the current working directory to be used as input to Sculpt. Each volume will be treated as a separate material within sculpt and a conforming mesh will be generated where volumes touch. If the Block command is used, one file per block will be used. Each block represents a separate material in Sculpt.

fileroot ’<root filename>’ Root of file names for output. When the sculpt parallel command is executed, Cubit will generate multiple files in the working directory used for input to the Sculpt application. The ’<root filename>’ will be used as the basis for naming these files.

OVERWRITE | no_overwrite By default, Cubit will overwrite an existing set of files with the same ’<root filename>’. To over-ride, use the no_overwrite option.

absolute_path By default, Cubit will write the relative path names of files used in the .run and .diatom files. To force absolute path names to be written, use the absolute_path option.

EXECUTE | no_execute By default, Cubit will attempt to run sculpt in parallel on the machine Cubit is currently running on. To generate just the required input to run Sculpt at a later time or on another machine, use this option. A file of the form <root filename>.run will be generated in the current working directory. (for example "model.run"). Executing the .run file from the linux command line should run sculpt in parallel. It can also be used to run sculpt on a cluster where a Cubit executable may not be available.

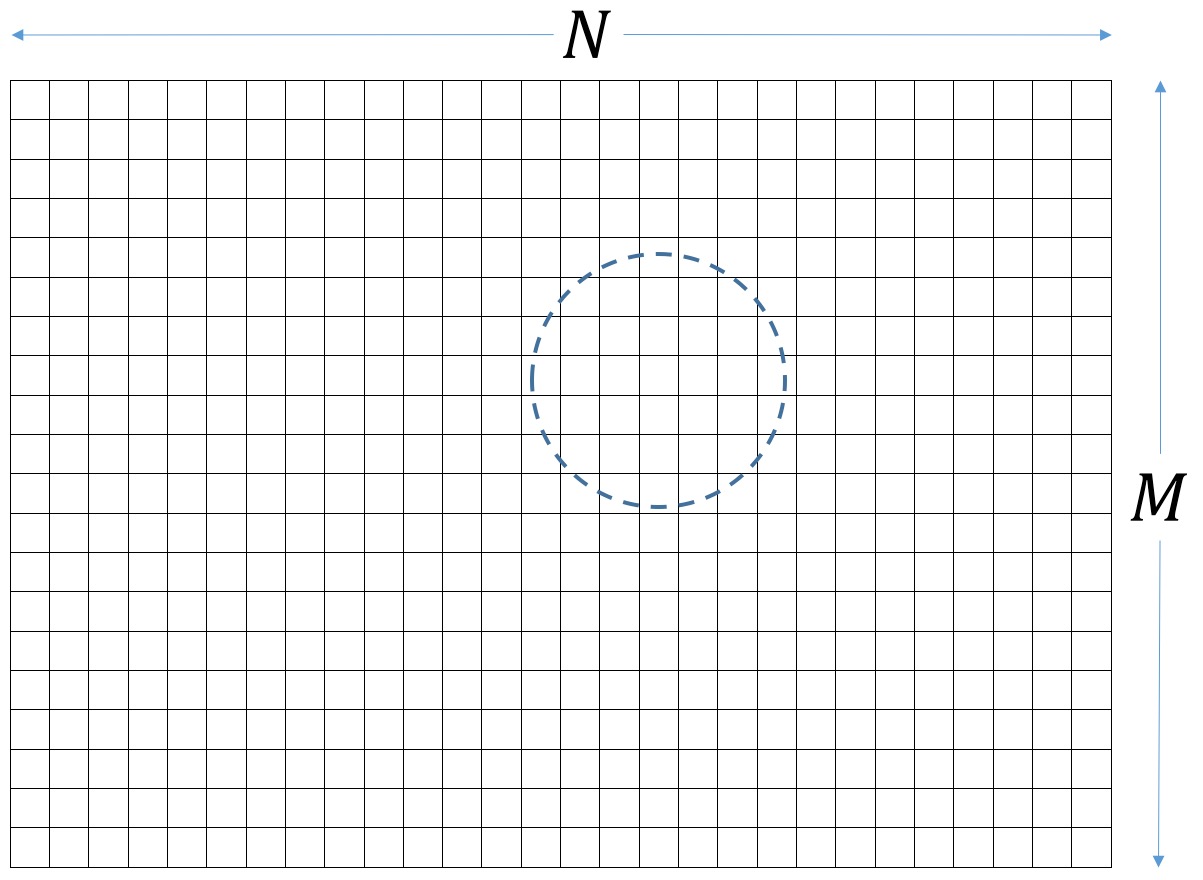

size <value> | autosize <value> The size option is the absolute cell size for the Cartesian grid and is the same as the cell_size option in sculpt. The autosize option is a value between 0 and 10. It represents a model independent size where 1 is the small size and 10 is large. This is the same scaling factor used in Cubit’s auto sizing but is divided by ten. A size value will be computed from the selected autosize and used as the absolute cell size for the base Cartesian grid.

box location <options> location options define the bounds of the Cartesian grid. The first Location <option> defines the minimum Cartesian coordinate of the grid and the second, the maximum. The <options> can be any valid method for defining a coordinate location in cubit. In most cases the position option can be used. The default is computed as an enclosing bounding box with 2.5 additional cells on each side.

COMBINE | no_combine If the no_combine option is used, following execution of Sculpt, the resulting exodus meshes will not be combined using the epu seacas tool. Otherwise the default will automatically combine the meshes generated by each processor into a single mesh. Note that epu should be installed on your system and the path to epu defined using the sculpt parallel path command. Epu is a code developed by Sandia National Laboratories and is part of the SEACAS tool suite. It combines multiple Exodus databases produced by a parallel application into a single Exodus database. The epu program should be included with distributions of Cubit beginning with Version 15.0.

IMPORT | no_import If the no_import option is used, following execution of Sculpt, the result will be not be imported into Cubit as a free mesh. The default IMPORT option will automatically import the mesh that was generated in Sculpt. If the no_combine option has been used, then multiple free meshes will be imported with duplicate nodes and faces at processor domain boundaries. Otherwise a single free mesh, the result of the epu code, will be imported. Note that the resulting mesh will not be associated with the original geometry, however Block (material) definitions will be maintained. In addition, a separate group will be generated for each imported mesh (One per processor). The default will automatically import the mesh following mesh generation in Sculpt.

SHOW | no_show If the no_show option is used, while the external Sculpt process is running, no ouput from the Sculpt application will be displayed to the command window. Otherwise, the default SHOW is used and output from the Sculpt application will be echoed to the Cubit command window. This option is only effective if the no_execute is not used.

CLEAN | no_clean If the clean option is used, temporary files generated during the sculpt parallel command will be deleted. This includes any exodus mesh files, .stl, .diatom, .log and .run files. The default for this option is CLEAN, therefore, use the no_clean option to keep any temporary files generated as part of the current Sculpt run.

gen_input_file <file name> | no_gen_input_file An input file with the given file name will be generated when the command is executed. This is a text file containing all sculpt options used in the command. The input file is intended to be used for batch execution of sculpt. To run sculpt from the operating system command line you would use the -i option. For example: sculpt -i myinputfile.i -j 4 where myinputfile.i is the name of the input file specified with the gen_input_file option and -j 4 is the number of processors to use.

debug <value> The debug option is used only as a developer debugging tool. It will set the debug processor and sleep upon execution to allow a debugger to be attached to the process.

5.4.11.1.4 Sculpt Parallel Path Command

Sculpt Parallel Path [List|Psculpt|Epu|Mpiexec] |

list |

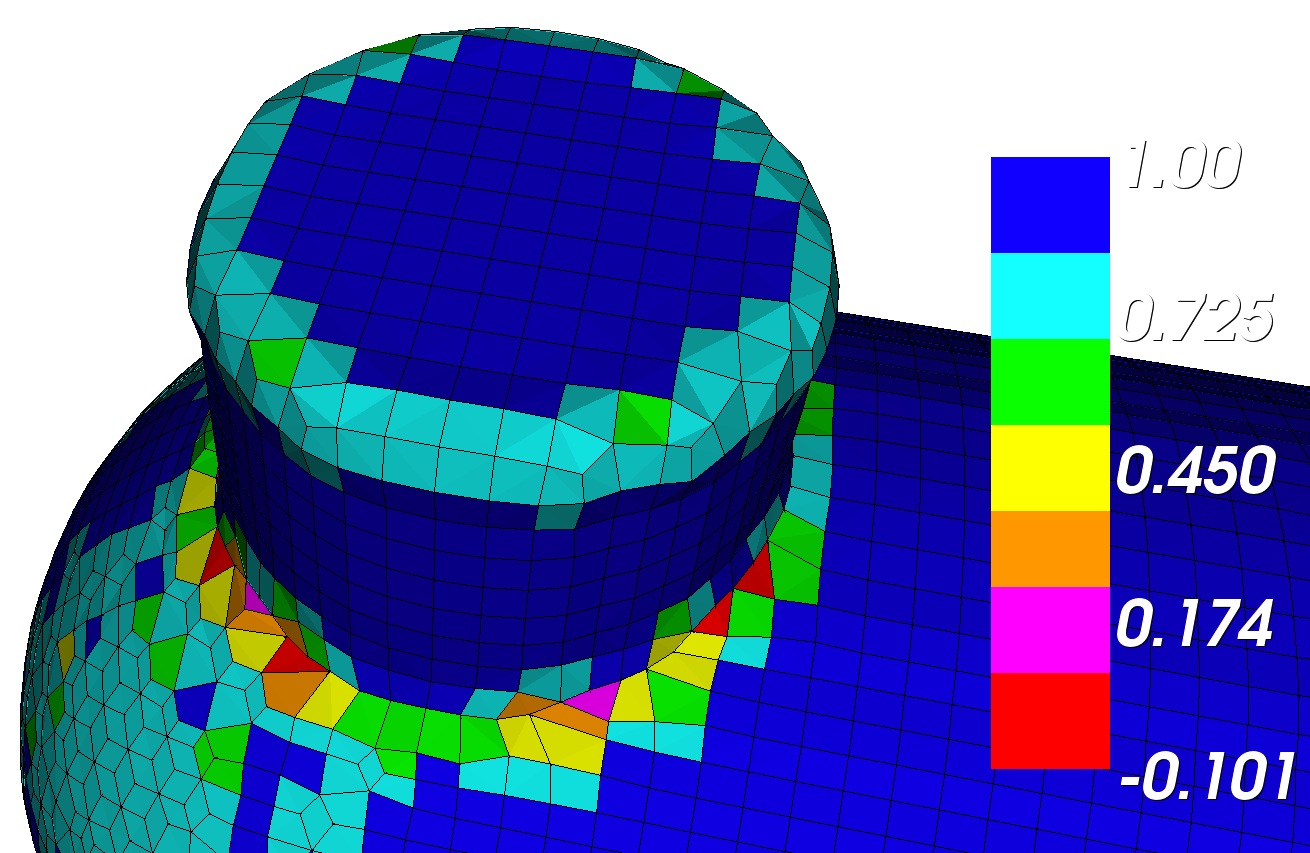

5.4.11.1.5 Sculpt Mesh Quality Control

In most cases, the Sculpt tool can be used without adjusting default values. Depending on the characteristics of the geometry to be meshed, the default values may not yield adequate mesh quality. Upon completion, Sculpt reports to the command line, a summary of the mesh that was generated. This includes a summary of the mesh quality. Care should be taken to review this summary to ensure the minimum mesh quality is in a range suitable for analysis.

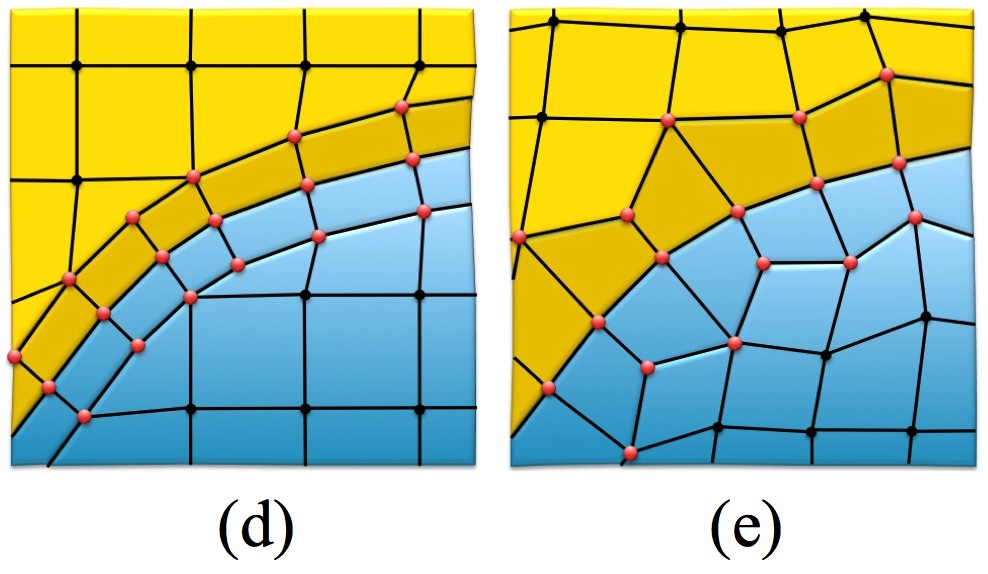

The element metric used for computing mesh quality in Sculpt is the Scaled Jacobian. This is a value between -1 and 1 that is a relative measure of the angles at the element’s nodes. A value of 1 indicates a perfect 90 degree angle between each of its edges. In most cases a value less than zero, or negtive Jacobian element, indicates an unusable mesh. Sculpt’s default settings try to achieve a minimum Scaled Jacobian of 0.2, which is normally usable in most analysis. The following discussion provides several options for adjusting the model or Sculpt parameters to help improve mesh quality.

- Locating poor mesh quality: When the Sculpt mesh has been imported back into CUBIT it is a good idea to display the element quality. You can do this with variations of the following commands:

quality hex all scaled jacobian

quality hex all draw mesh Identify regions where hexes are poor quality and zoom in to these regions.

Modifying the geometry: Zooming in to poor quality elements may reveal that the mesh does not adequately represent the underlying geometry. In some cases you may find that small features, or small gaps between parts may be on the order of the size of the Sculpt cell size. If these features are not important to the analysis, you may consider using Cubit’s geometry modification tools to remove features or close small gaps.

Modifying the cell size: In cases where small geometric features or gaps are important to the simulation, it may be necessary to use a smaller base cell size. Use the size or autosize input parameters or increase the numbers of intervals. Normally to adequately capture a feature you would want the cell size to be no greater than about 1/3 to 1/2 the size of the smallest feature you would want to represent in the simulation.

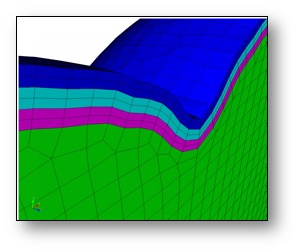

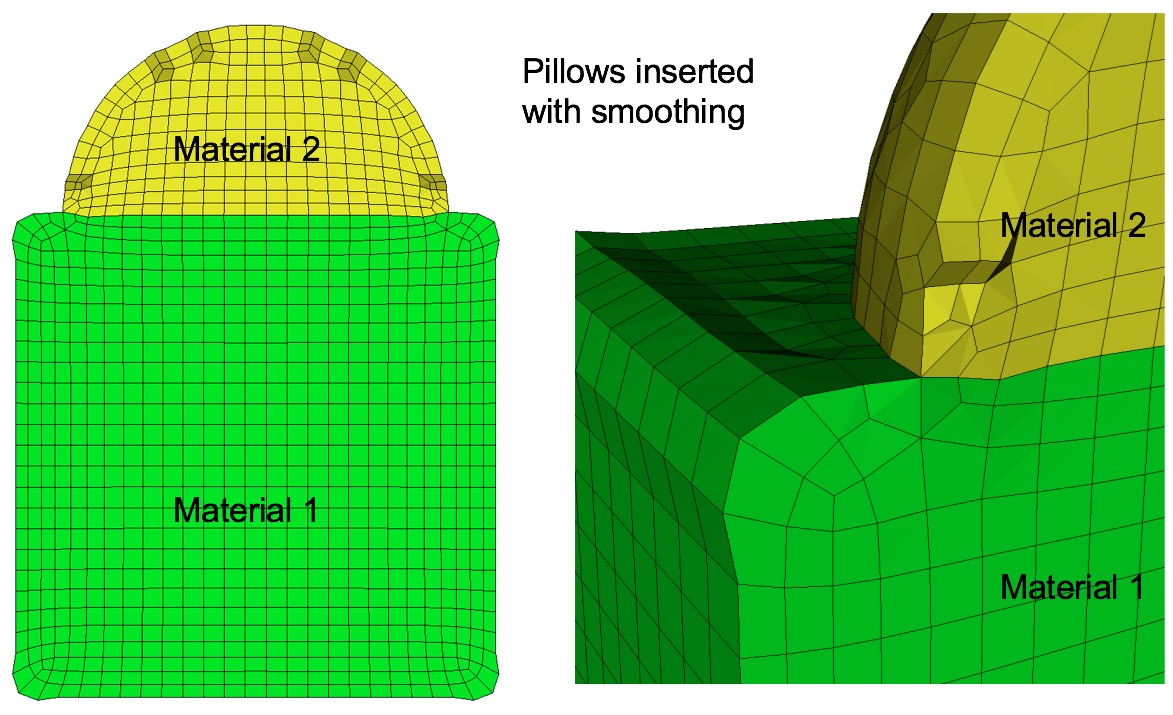

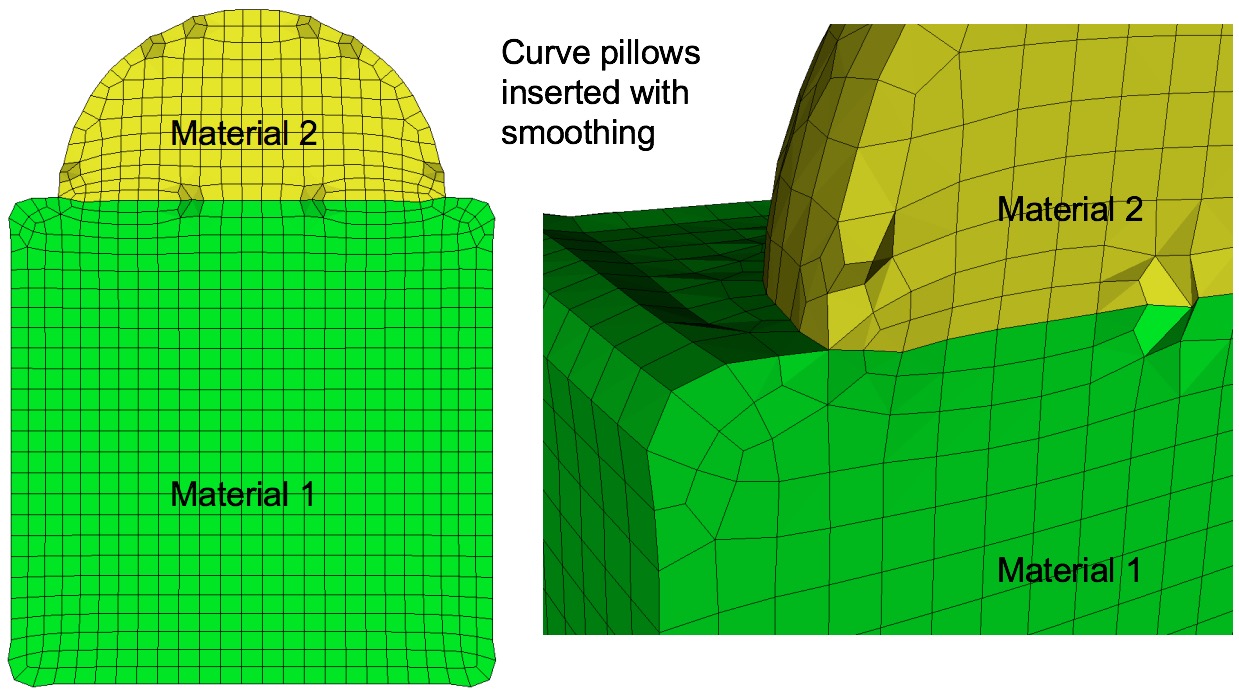

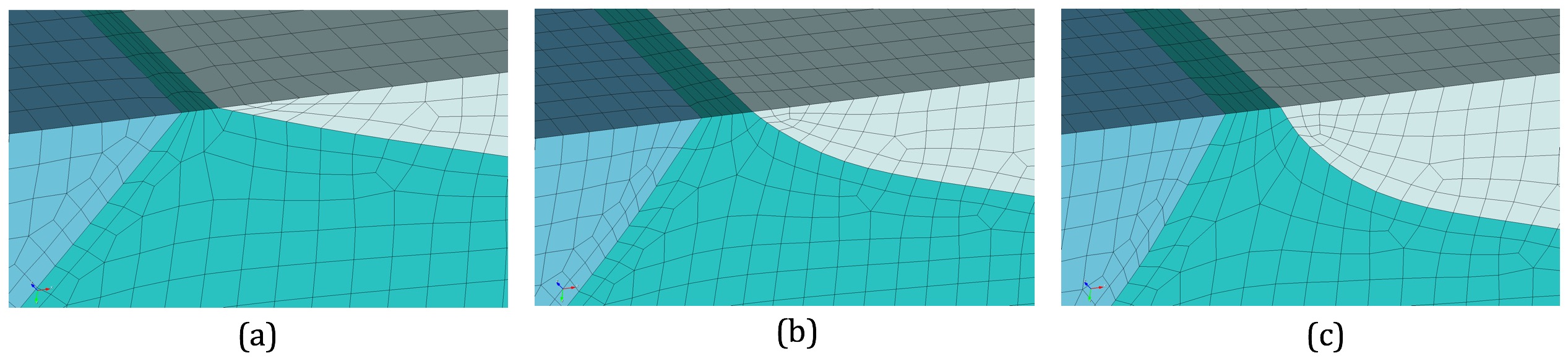

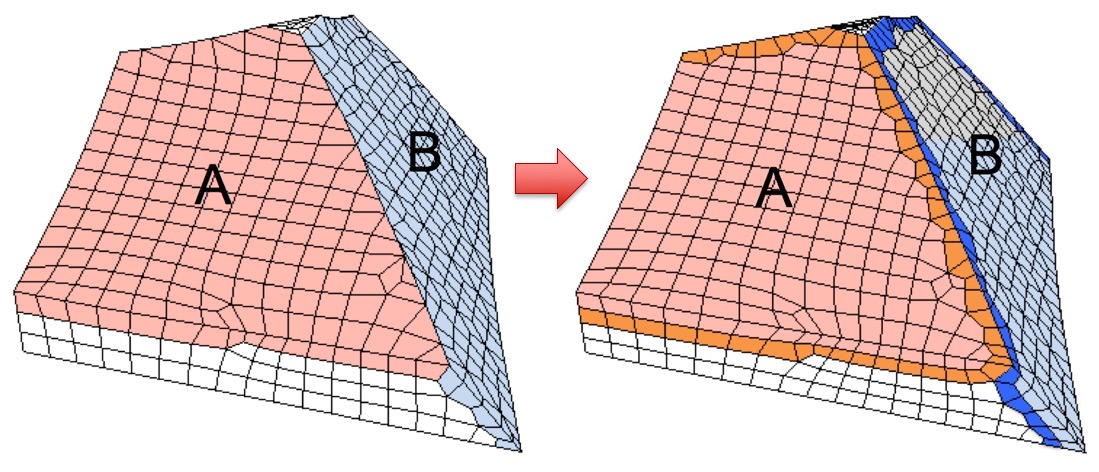

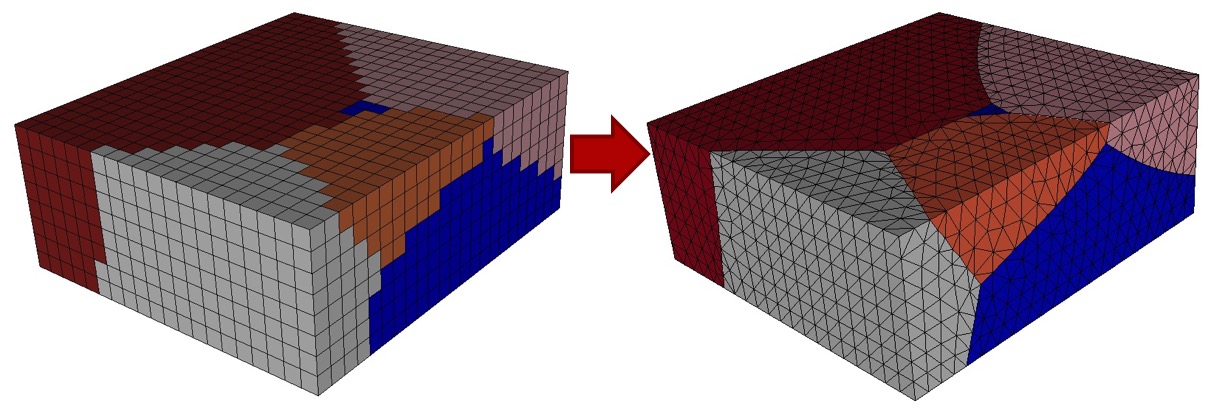

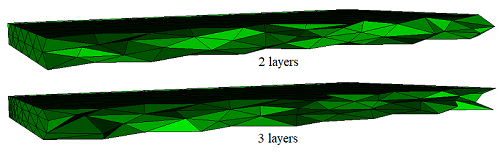

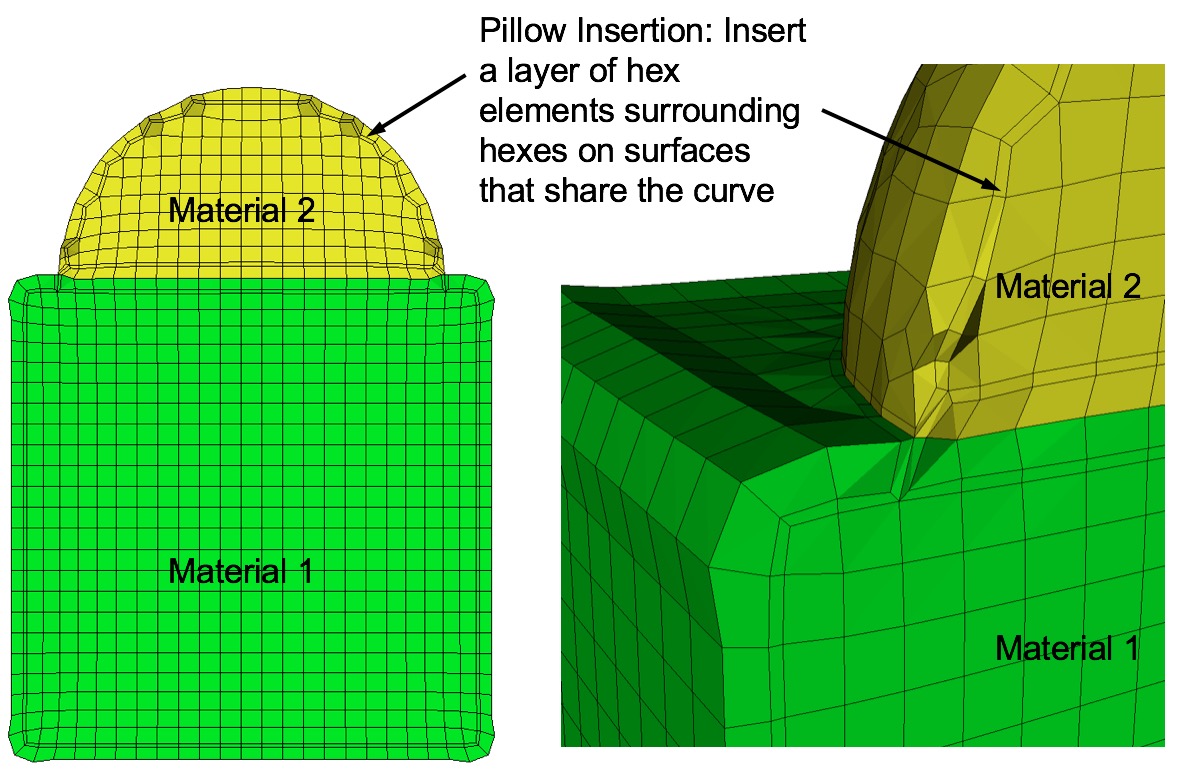

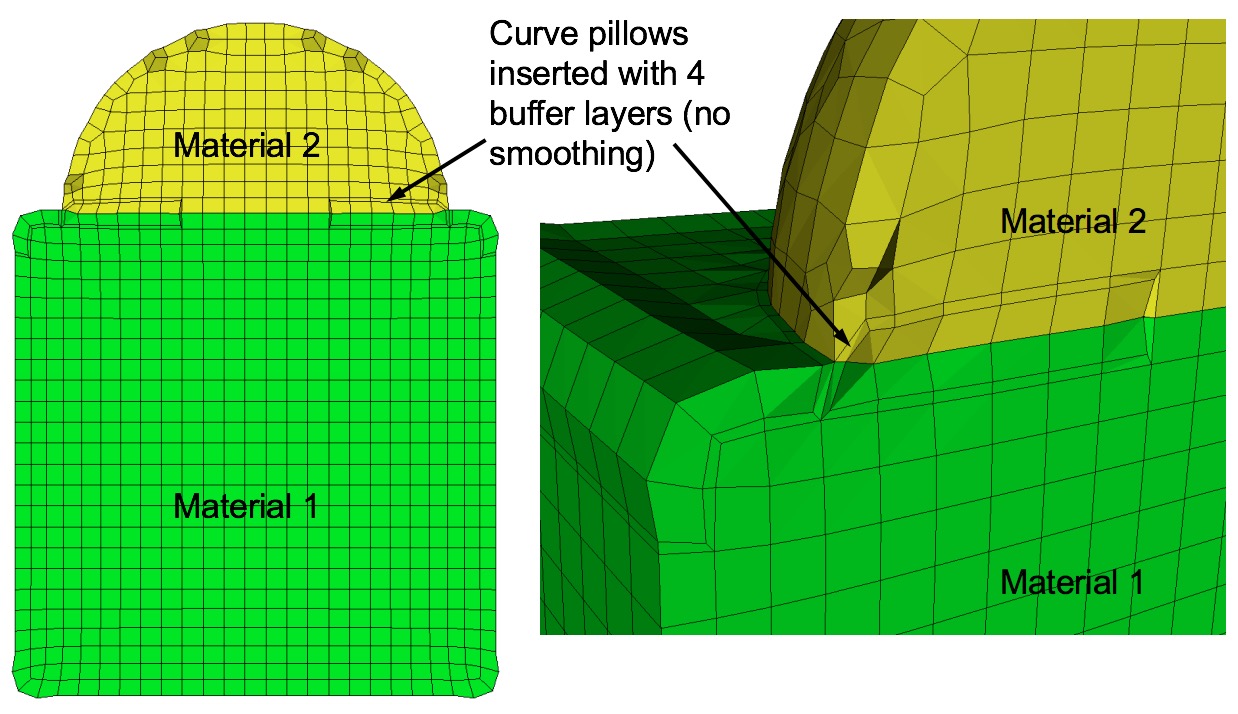

Turning on Pillowing for multiple materials: For models that have more than one material that share an interface, unless the geometry is precisely aligned with the global axis, it is usually a good idea to turn on pillowing. Pillowing automatically inserts an additional layer of hexes at interface boundaries to improve mesh quality. Without pillowing may notice inverted or poor quality elements at curve interfaces where 2 or more materials meet.

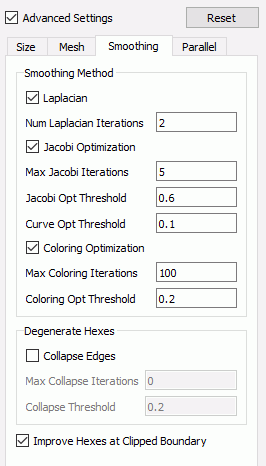

- Modifying smoothing parameters: Sculpt includes a tiered approach to smoothing to improve element quality. It starts by applying smoothing to all nodes in the mesh and progressively restricts the smoothing operations to only those nodes that fall below a user-defined scaled Jacobian threshold. Default numbers of iterations and thresholds for each smoothing phase have been tuned for general use, however it may be worthwhile to adjust these parameters. The three smoothing phases include: Observing the mesh quality output to the command line following each smoothing iteration can provide some insight on the effect of modifying smoothing parameters.

Laplacian Smoothing: Applied to all elements. Very inexpensive fast approach to improve quality, but can result in degraded element quality if applied to excess. A fixed default of 2 iterations is applied to all hexes. Increasing the num_laplace parameter can improve some cases, especially convex shapes

Optimization Smoothing: Applied only to elements who’s scaled Jacobian falls below the opt_threshold parameter (default 0.6) and their surrounding elements. This approach uses a more expensive optimization technique to improve regions of elements simultaneously. The max_opt_iters parameter can control the maximum number of iterations applied (default is 5). Iterations will terminate, however, if no further improvement is detected. Because this method optimizes node locations simultaneously, neighboring nodes with competing optimum can sometimes limit mesh quality.

Spot Optimization: Also known as parallel coloring, is applied only to elements who’s element quality falls below the pcol_threshold parameter (default 0.2). This technique is the most expensive of the techniques, but focusses only on nodes that are immediately adjacent to poor quality hexes. Each node is smoothed independently of its neighbors, and may require a high number of iterations using the max_pcol_iters to achieve desired results. Increasing the pcol_threshold and max_pcol_iters may yield improved results.

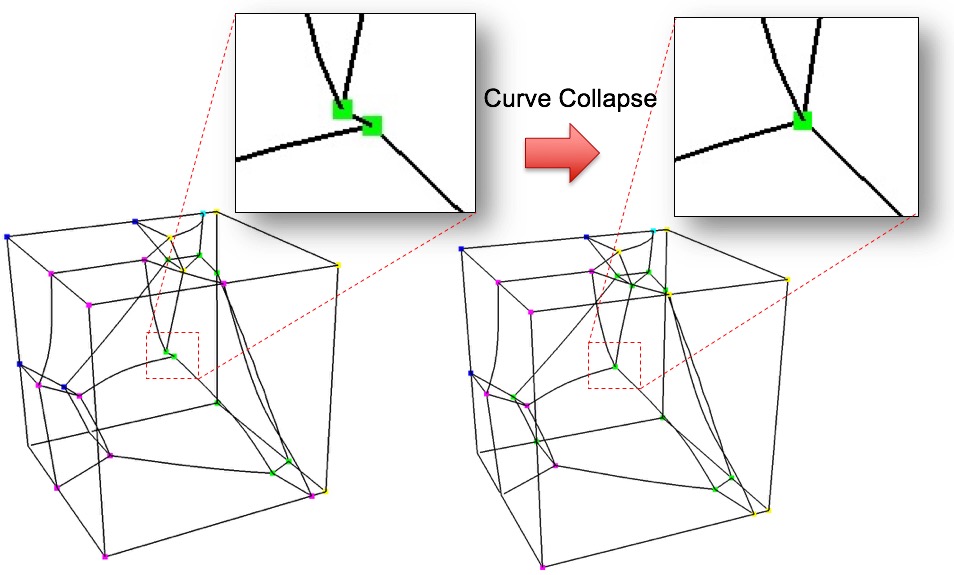

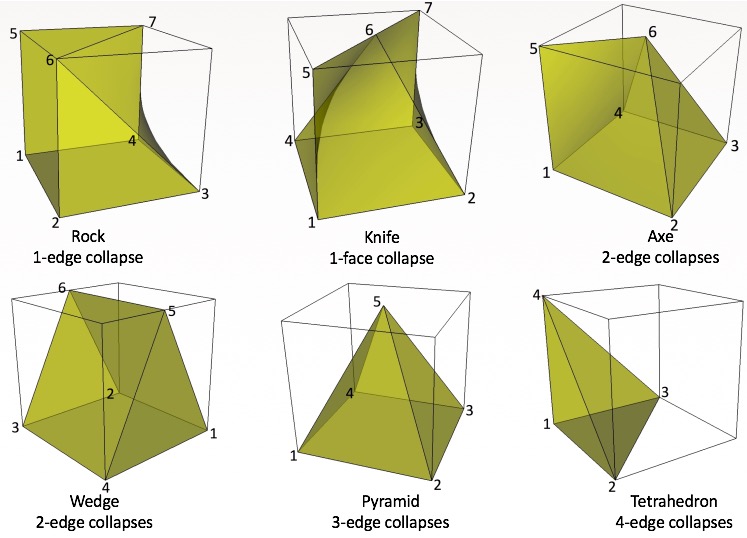

Creating degenerate hexes: Some geometries will not permit a usable mesh with a traditional all-hex mesh. Sculpt includes the option to automatically and selectively collapse element edges to improve low-quality elements. The max_deg_iters and the deg_threshold values are used to control the creation of degenerates. Degenerate elements are treated as standard hex elements, but use repeated nodes in the eight-node connectivity array.

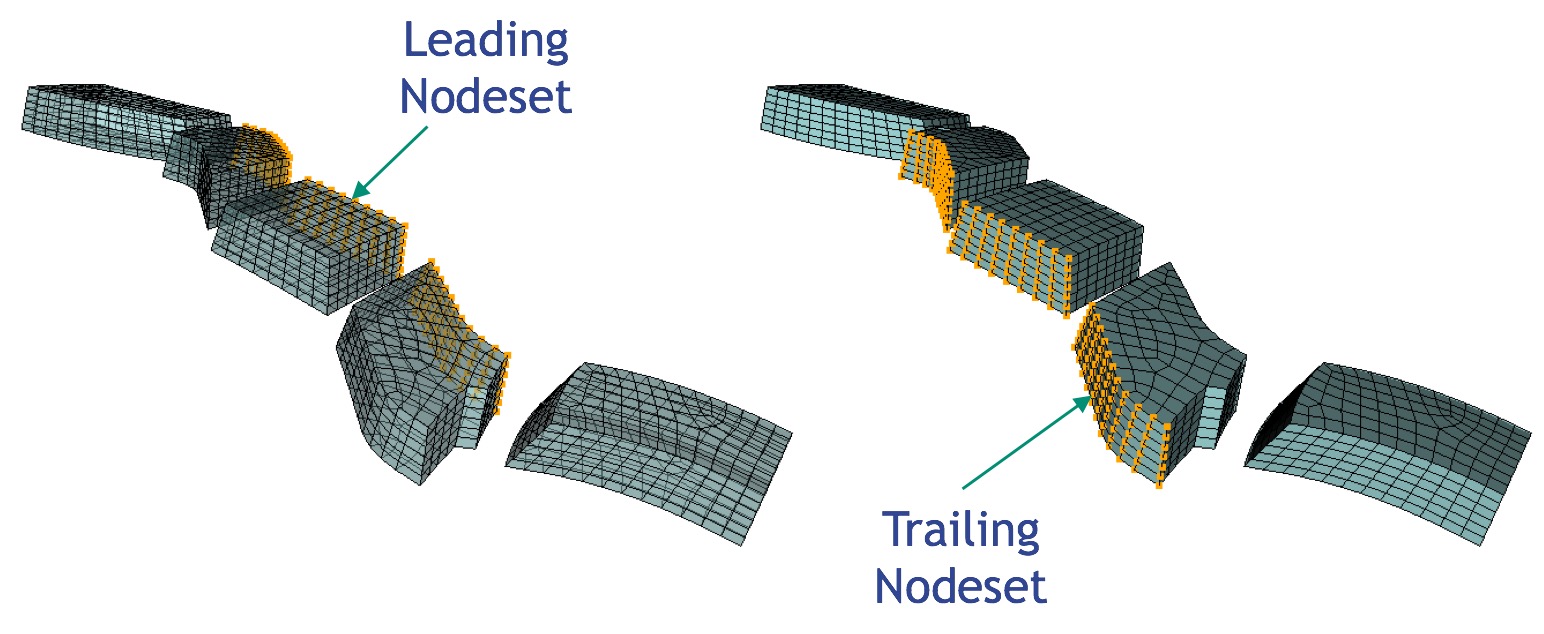

Creating hex-dominant mesh Another option for avoiding mesh quality issues is to generate a few tet elements in the mesh using the htet option. With this option you can specify a scaled Jacobian threshold value below which hexes will be converted to tet elements. The interface between hex and tet elements is managed by an automatically defined set of nodesets and sidesets that describe where multi-point constraints will be applied.

Defeaturing The defeature option does an initial filter on the cells of the base grid and attempts to reassign the material ID for cells that meet certain criteria. These are cases where a small grouping of cells form a small volume, or where protrusions exist that would otherwise be difficult or impossible to mesh with good quality elements. By reassigning the cells in these locations, in many cases it will allow the mesh to be acceptable. This operation may result in small changes to the boundary or surface definitions, however usually small enough to still be a reasonable approximation.

5.4.11.1.6 Sculpt Examples

sphere rad 1 |

5.4.11.1.6.1 Basic Sculpt

sculpt parallel |

5.4.11.1.6.2 Size and Bounding Box

delete mesh |

5.4.11.1.6.3 Meshing the Void

delete mesh |

5.4.11.1.6.4 Automatic Sideset Definition

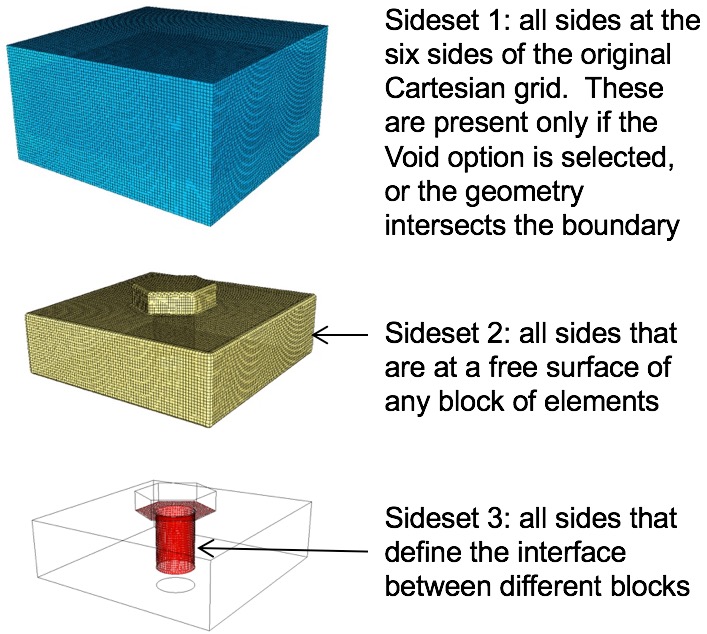

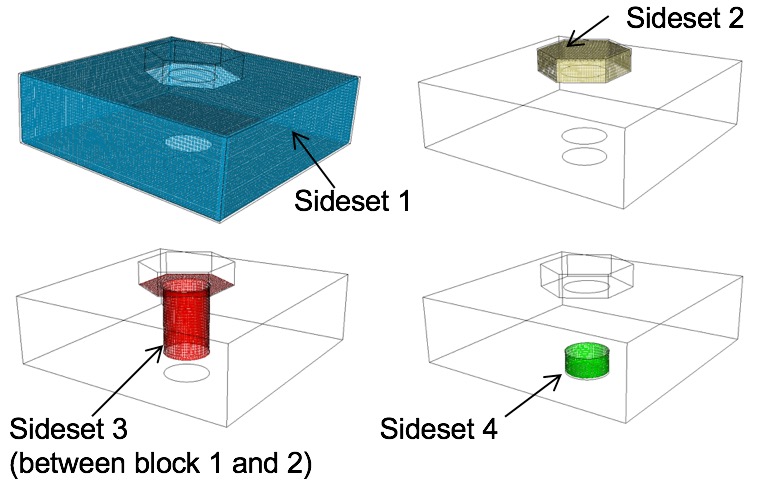

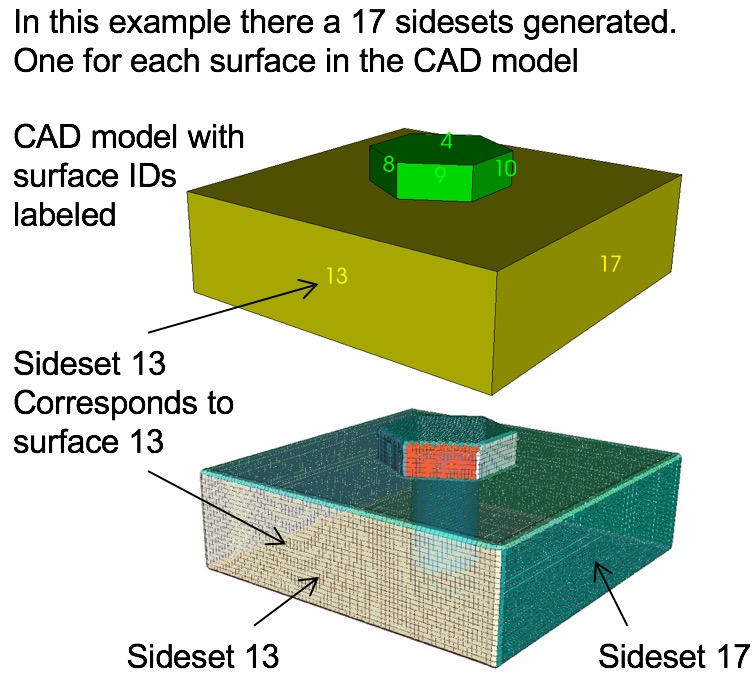

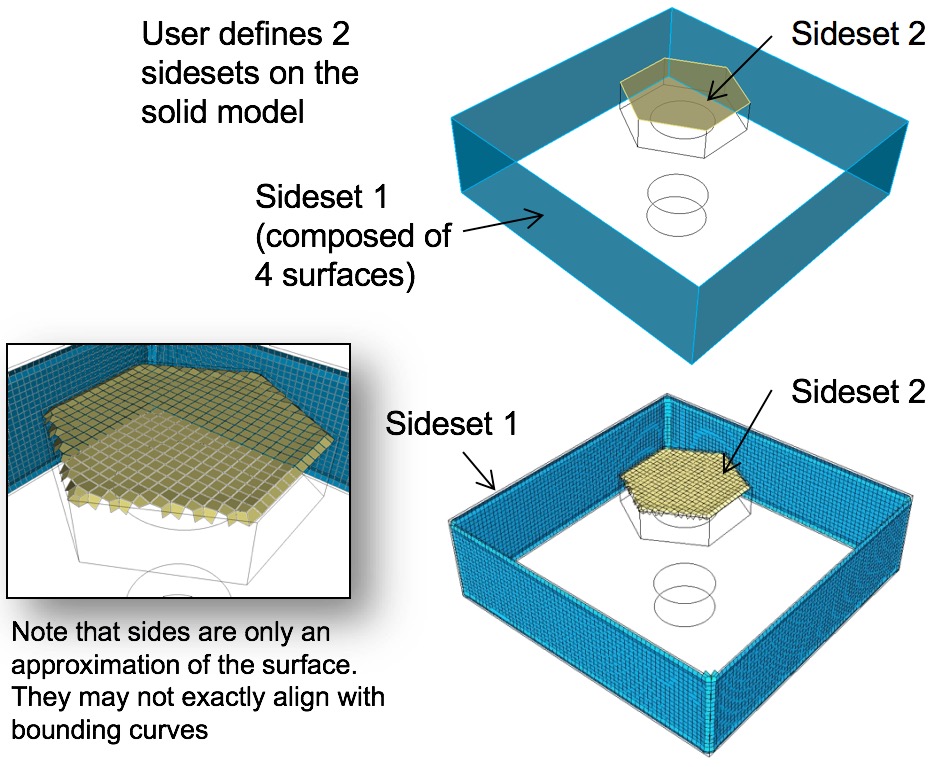

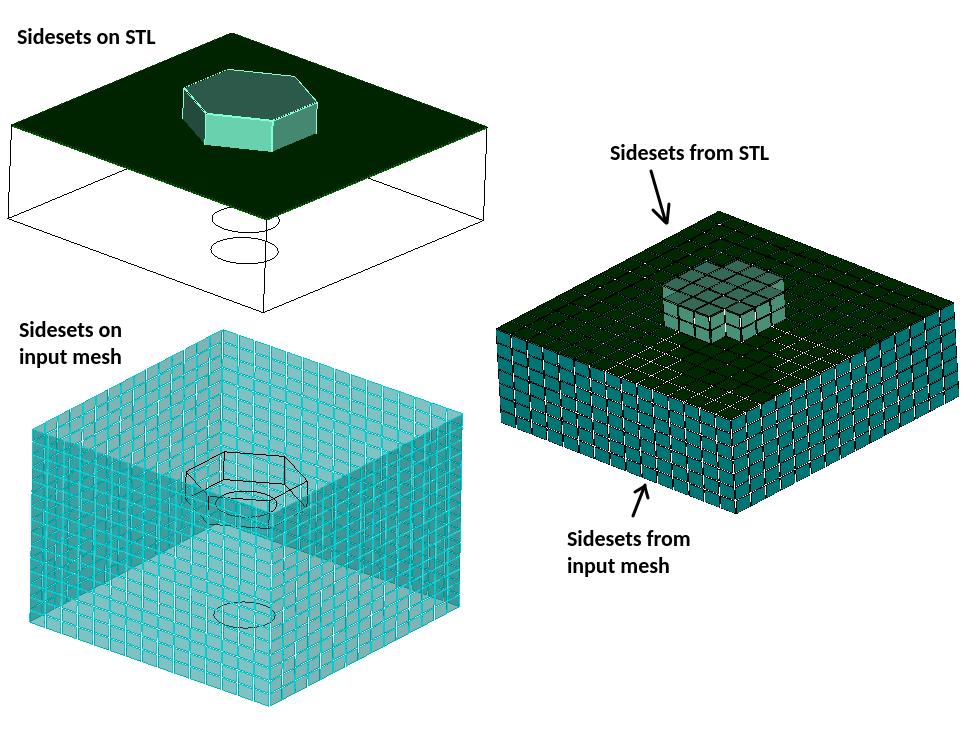

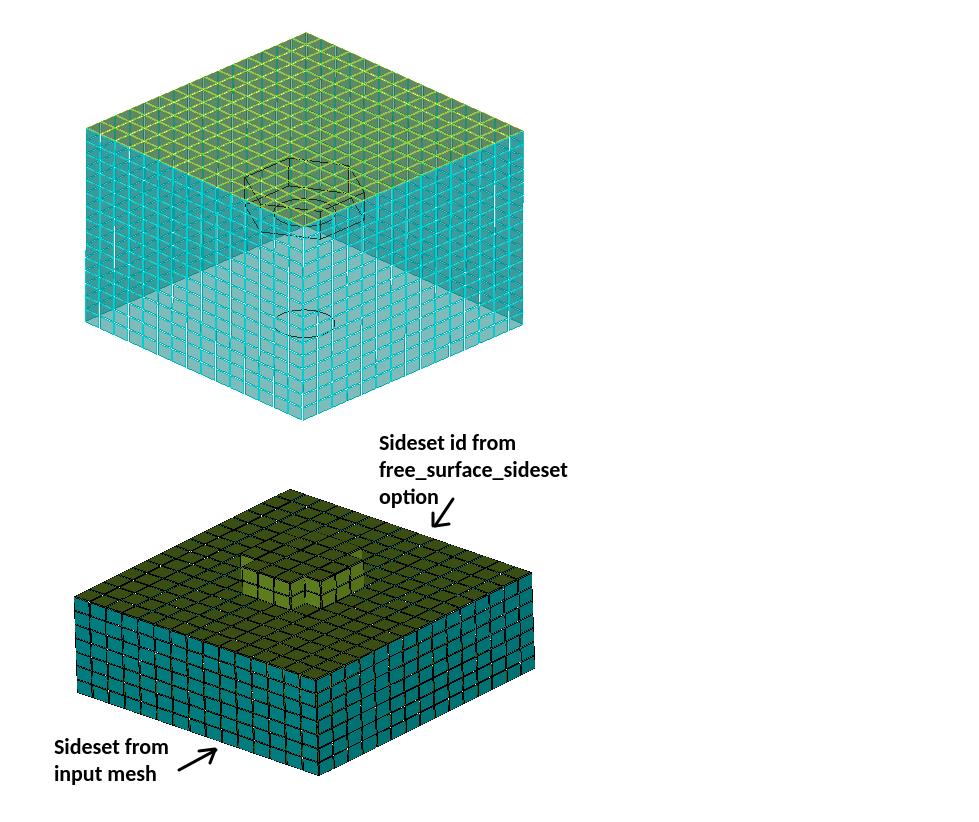

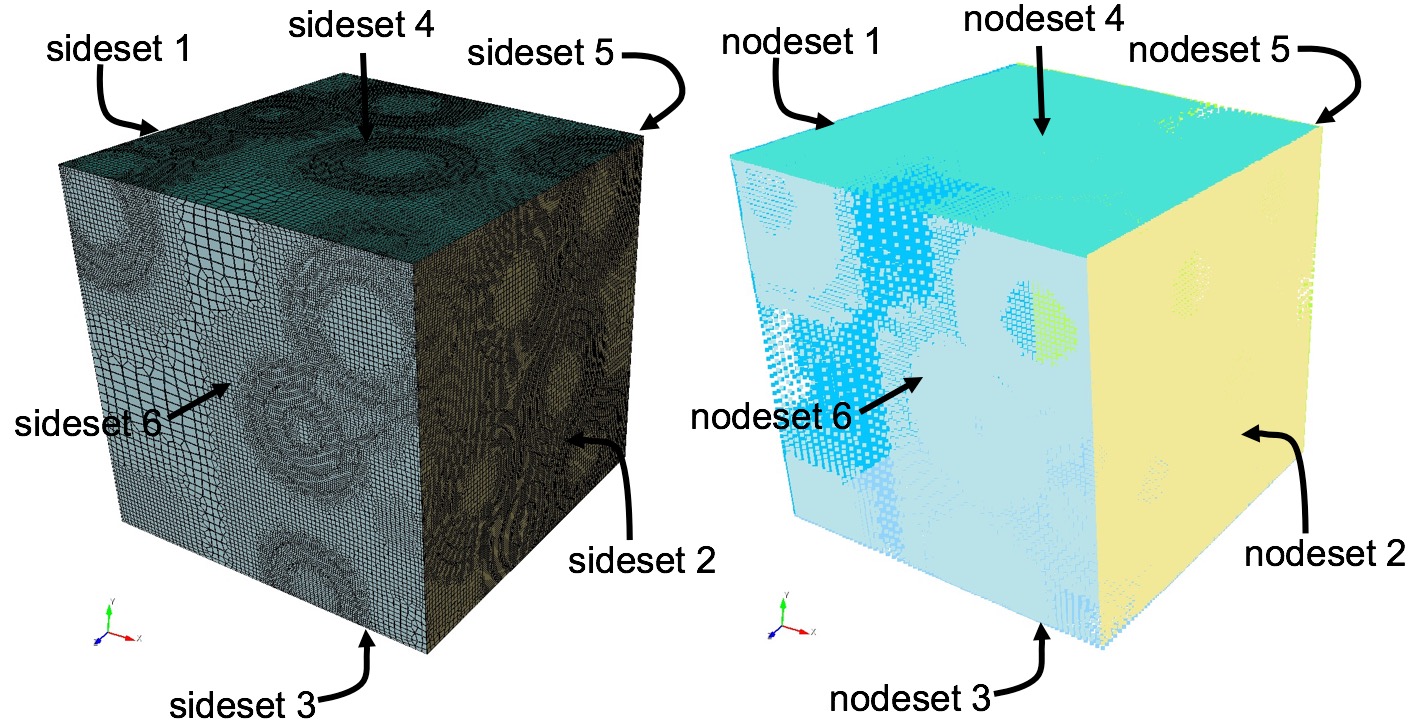

In this example we illustrate the use of the sideset option.

Generating sidesets on the free mesh with Cubit: Sideset boundary conditions can be manually created on the resulting free mesh from Sculpt using the standard sideset <sideset_id> face <id_range> syntax. The group seed command is also useful in grouping faces based on a feature angle to be used in a single sideset.

delete mesh |

Interfaces between materials

Exterior surfaces

Surfaces at the domain boundary

See the sideset option above for a description of other options for generating sidesets in Sculpt.

5.4.11.1.6.5 Running Sculpt Stand-Alone

This example illustrates how to set up the files necessary to run Sculpt as a stand-alone process. This can be done on the same desktop machine or moved to a larger cluster machine more suited for parallel processing.

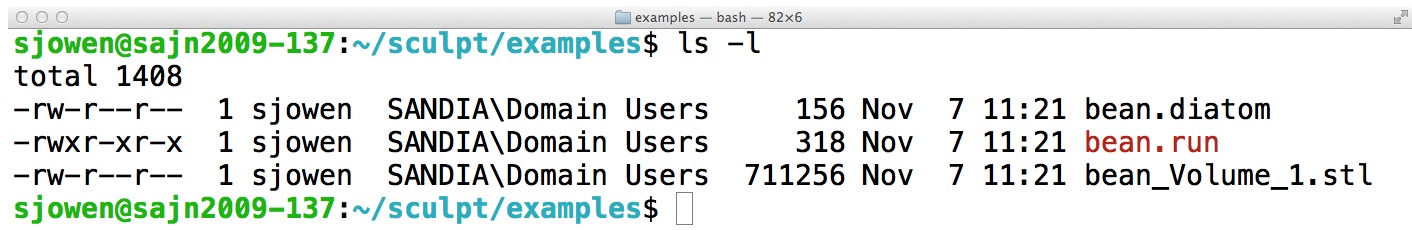

cd "path/to/my/sculpt/examples" |

delete mesh |

In this case, we used the no_execute option which does not invoke the Sculpt application. Instead it will write a series of files to the working directory. The fileroot option defines the base file name for the files that will be written; in this case "bean". We also use the processors option to set the number of processors to be used to 8.

bean.diatom: Diatoms is a file format used by Sandia’s CTH and Alegra analysis programs that includes a rich constructive solid geometry definition. A series of directives for constructing and orienting primitives to build a complete solid model can be used. Included in the Diatom description is an STL import option. While any standard Diatom description may be used as input to Sculpt, for Cubit’s purposes, only the STL option is used. This file contains a listing of all STL files that will be used as input to Sculpt.

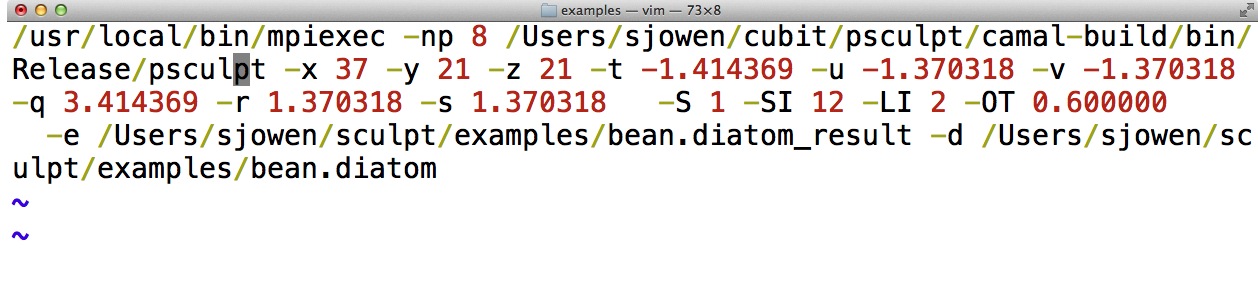

bean.run: The .run file contains the unix command line for running sculpt. Note that the file permissions have been set to execute to allow this file to be used as a unix script. Figure 248 shows the .run file for this example. Note that the command uses mpiexec and the psculpt executables, along with their full path. These paths may need to be edited when running on a different machine. It also includes the default parameters for setting the sizes, bounding box and smoothing parameters that have been computed by Cubit.

bean_Volume_1.stl: The STL file is a copy of the geometric model. In our case, it is a representation of the cylinder and sphere object we have been working with. The STL format is a set of triangles that describe the surfaces of the object. One STL file will be generated for each Volume. If the Block option is used, then one file for each Block would be created.

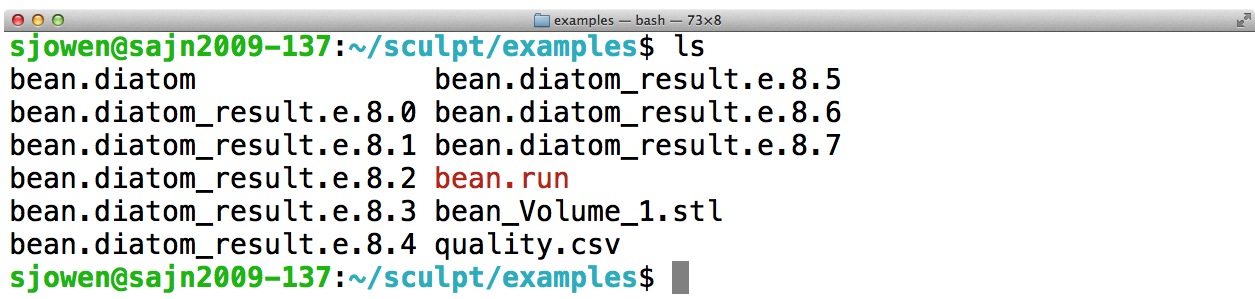

./bean.run |

If Sculpt is to be run on a different machine, copy the files in the working directory to the other machine and issue the same command. Remember to change the path to the mpiexec and psculpt executables to match those on the new machine. For running on cluster machines that have scheduling of resources, check with your system administrator for how to submit a job for running.

Note that 8 exodus files have been generated, 1 from each processor. These files can be used by themselves or used as-is for use in a simlation, or they can be combined into a single file. The exodus files produced by Sculpt include all appropriate parallel communication information as defined by the Nemesis format. Nemesis is an extension of Sandia’s Exodus II format that also includes appropriate parallel communication information.

epu -p 8 bean.diatom_result |

import mesh "bean.diatom_result.e" no_geom |

The result should be the same mesh we generated previously that is shown in Figure 243.

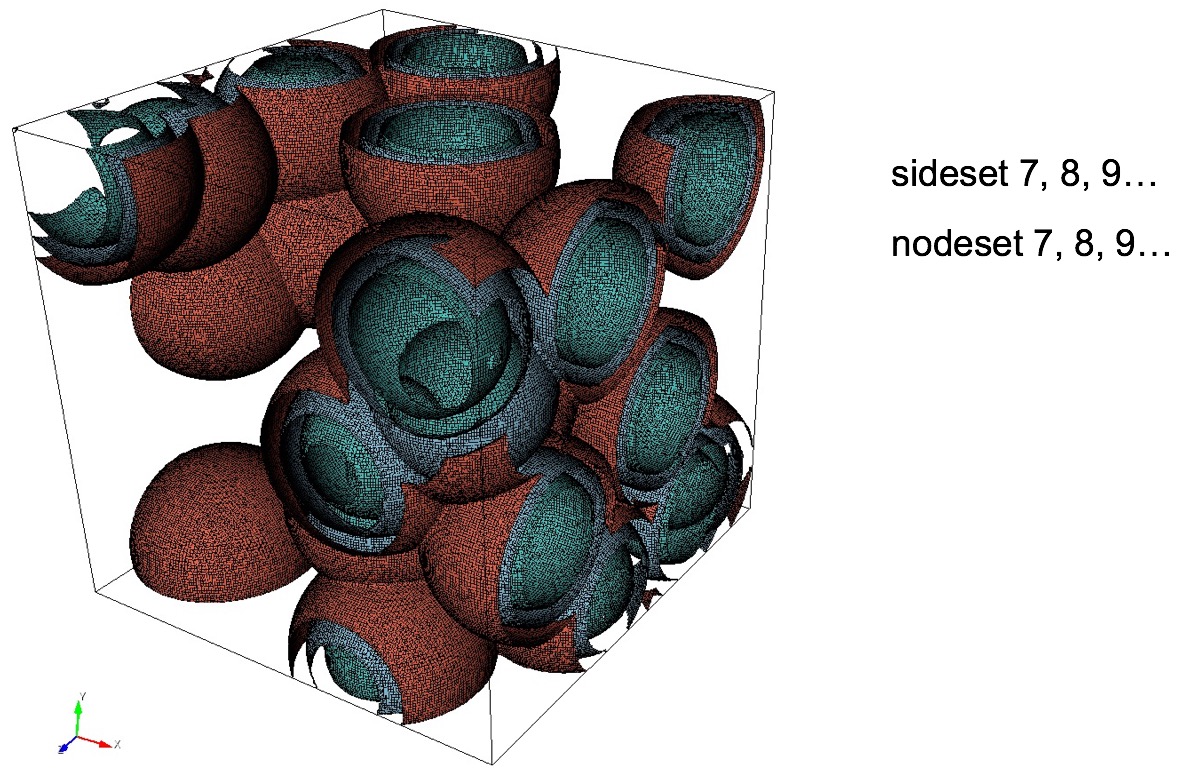

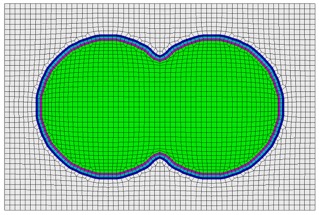

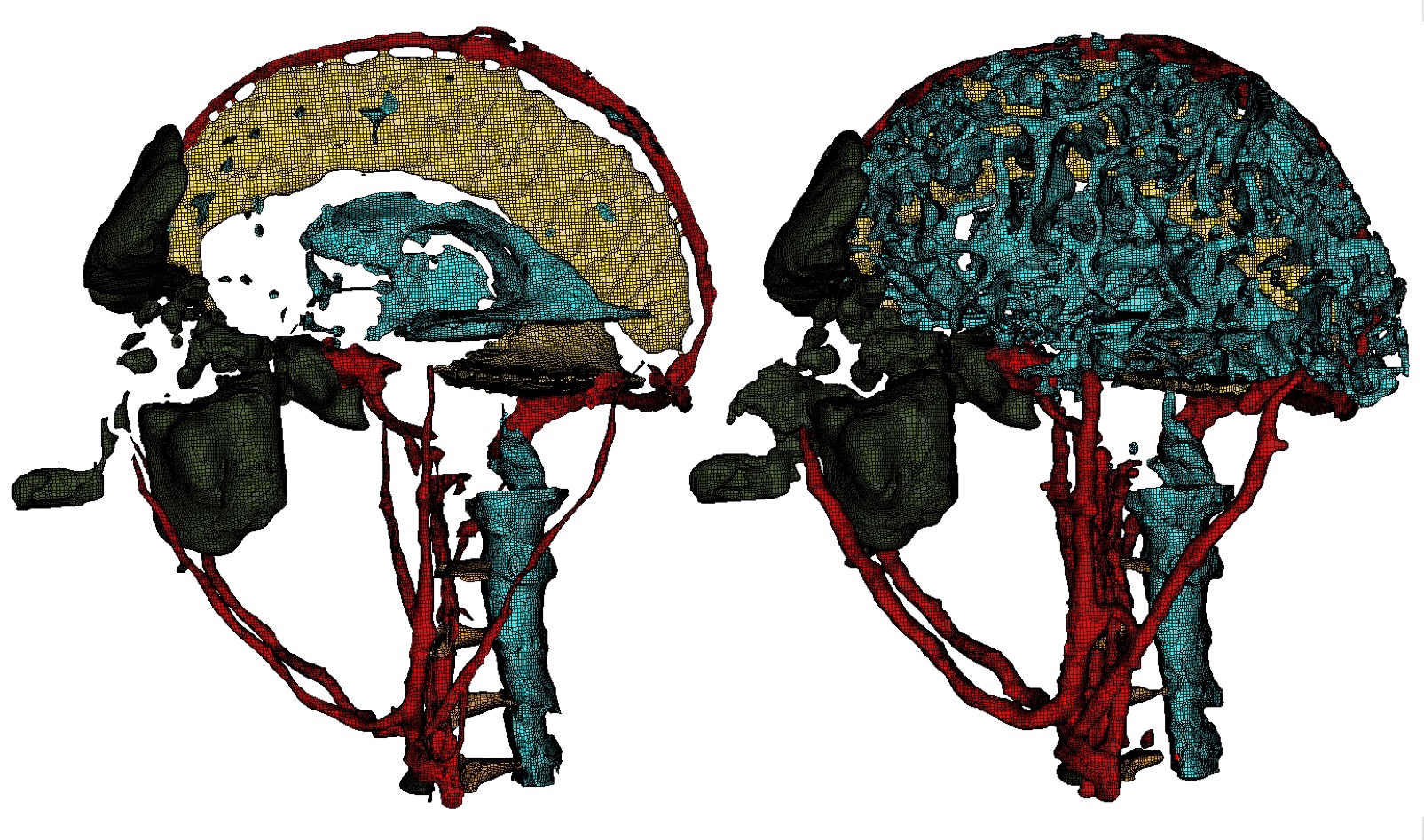

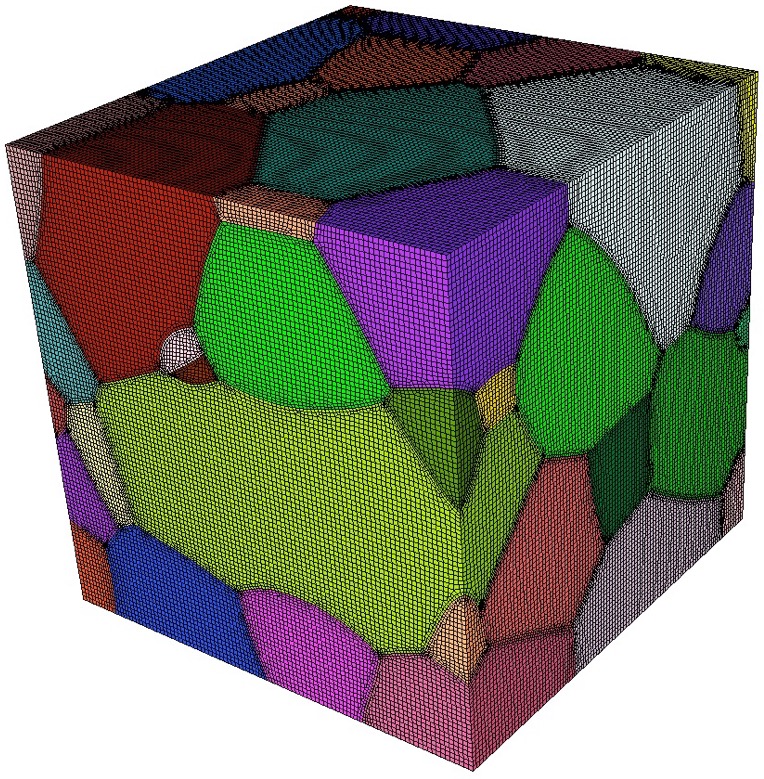

5.4.11.1.6.6 Meshing Multiple Materials With Sculpt

delete mesh |

sculpt parallel size 0.075 |

We should also note that imprint/merge operations typically needed, were also not required. While it is usually best to avoid overlaps to avoid ambiguities in the topology, Sculpt is able to generate a mesh giving precedence to the most recently defined materials. Merging is performed strictly by geometric proximity. Volumes closer than about one half the user input size will normally be automatically merged.

quality hex all scaled jacobian draw mesh |

delete mesh |

Figure 255: Cutaway of mesh reveals the additional layer of hexes surrounding each surface when the pillow option is used.

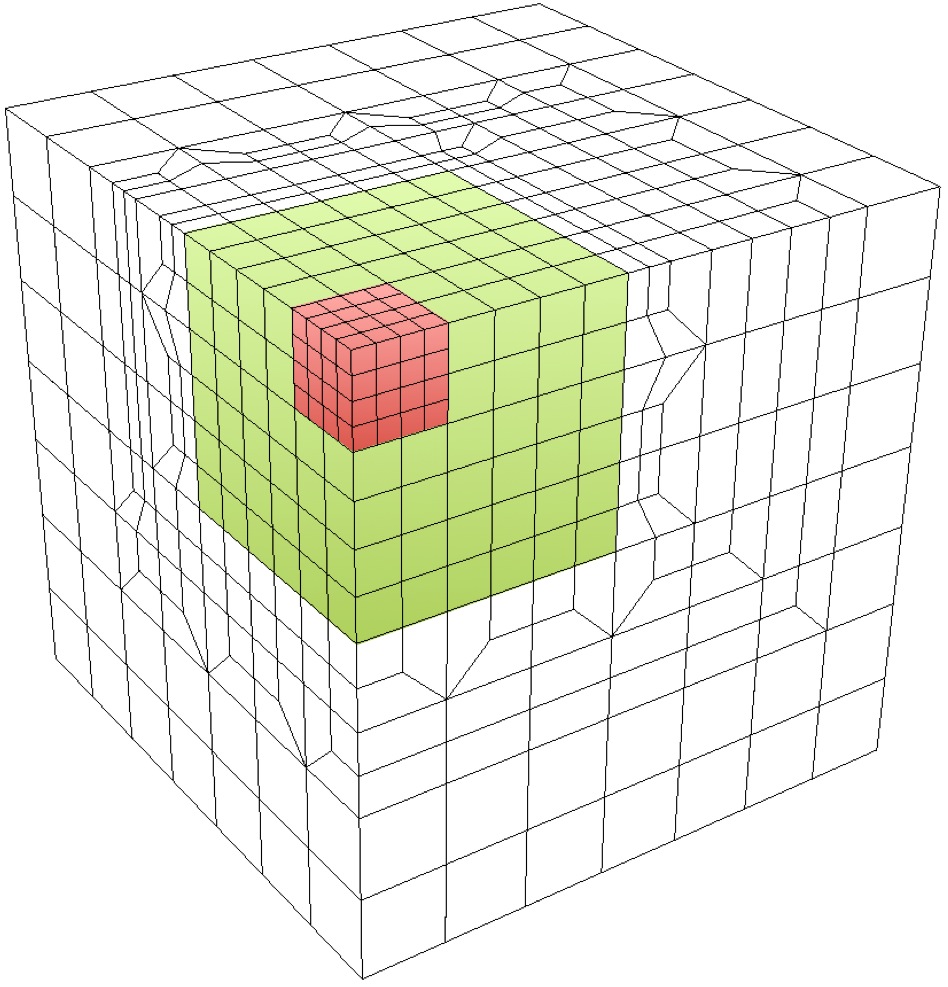

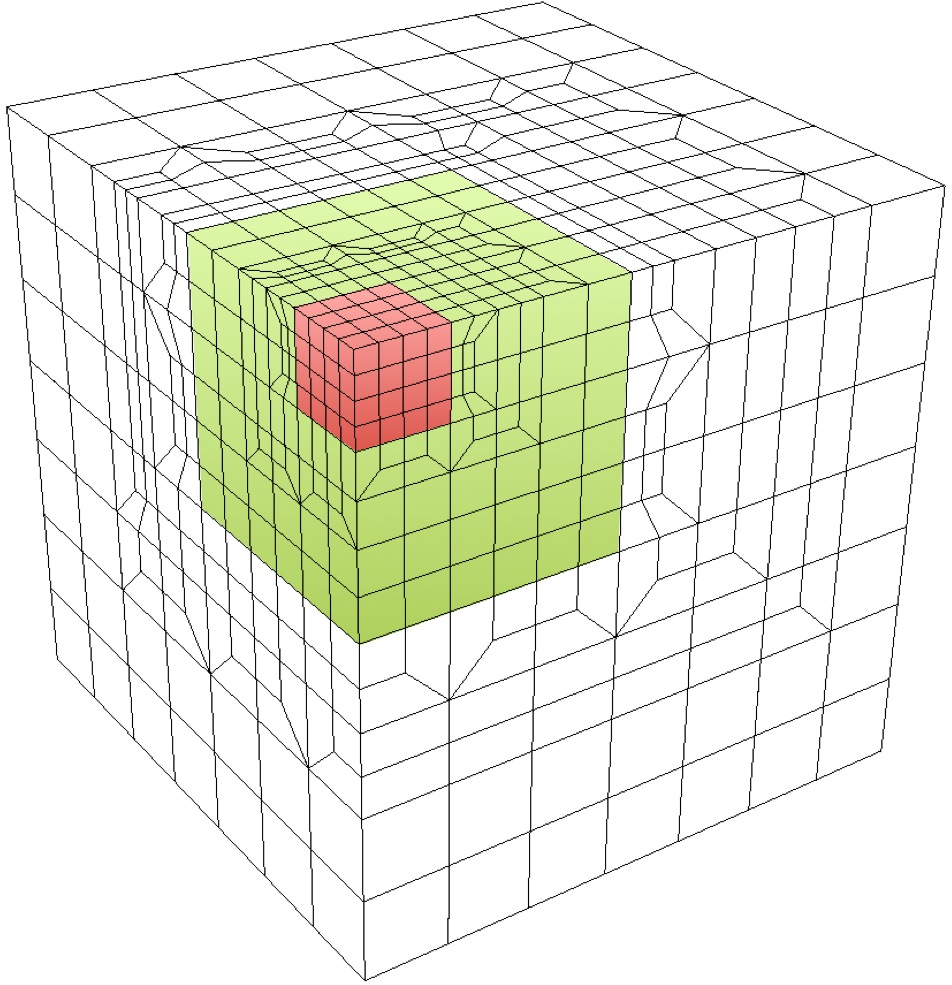

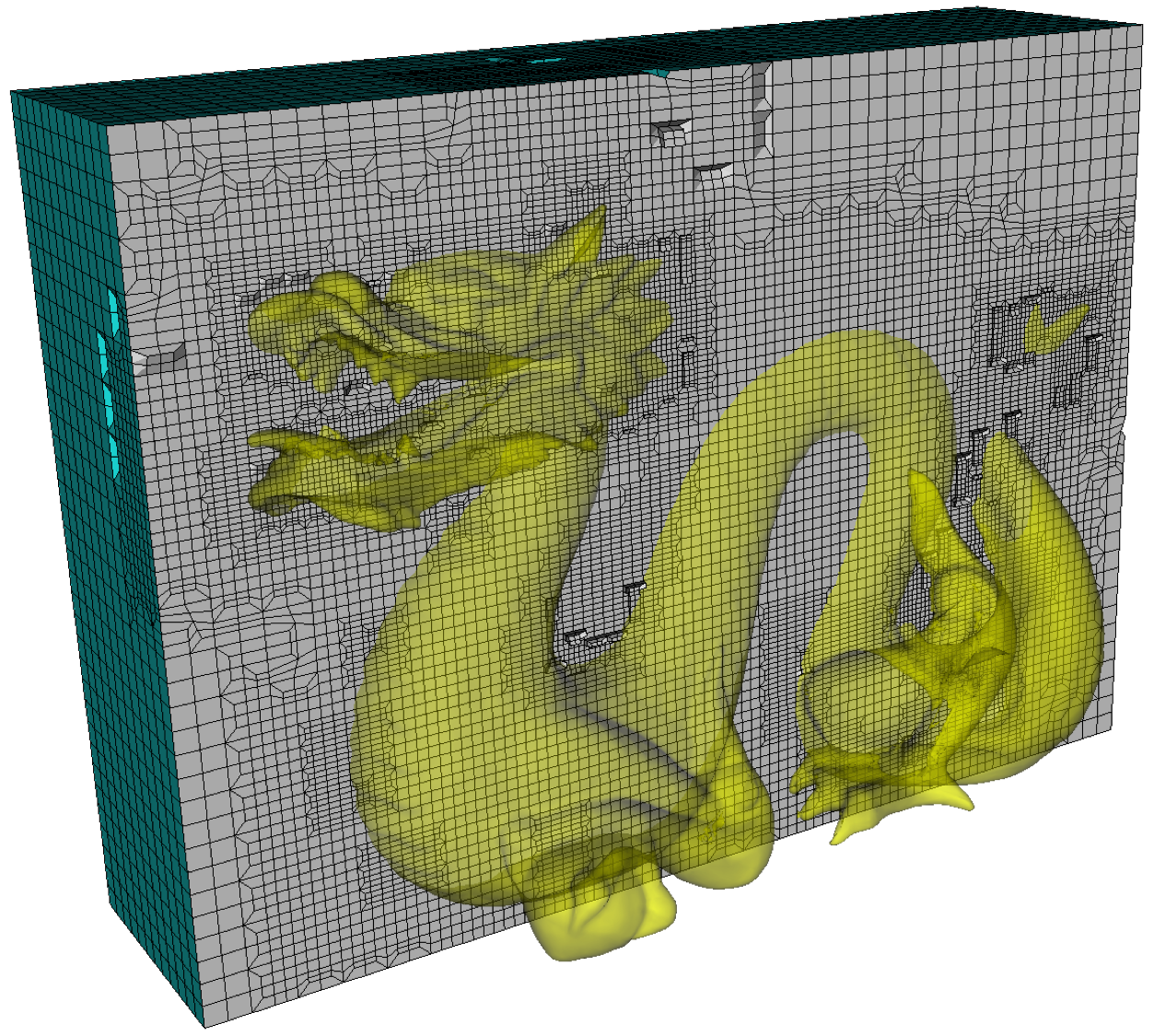

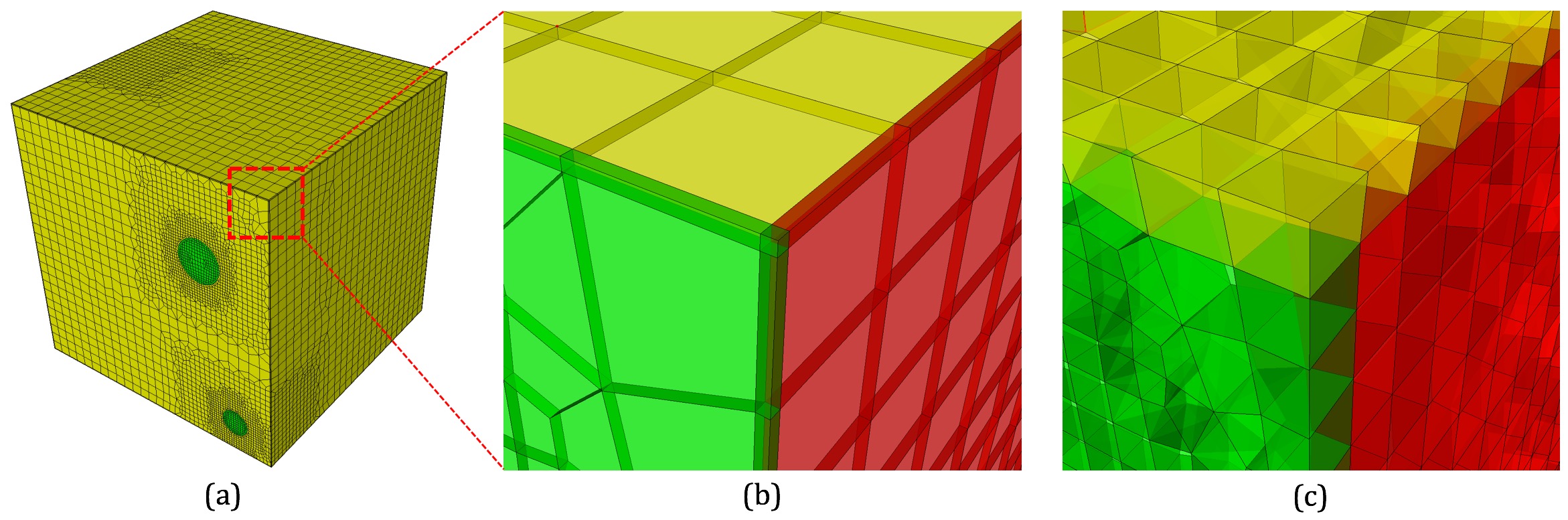

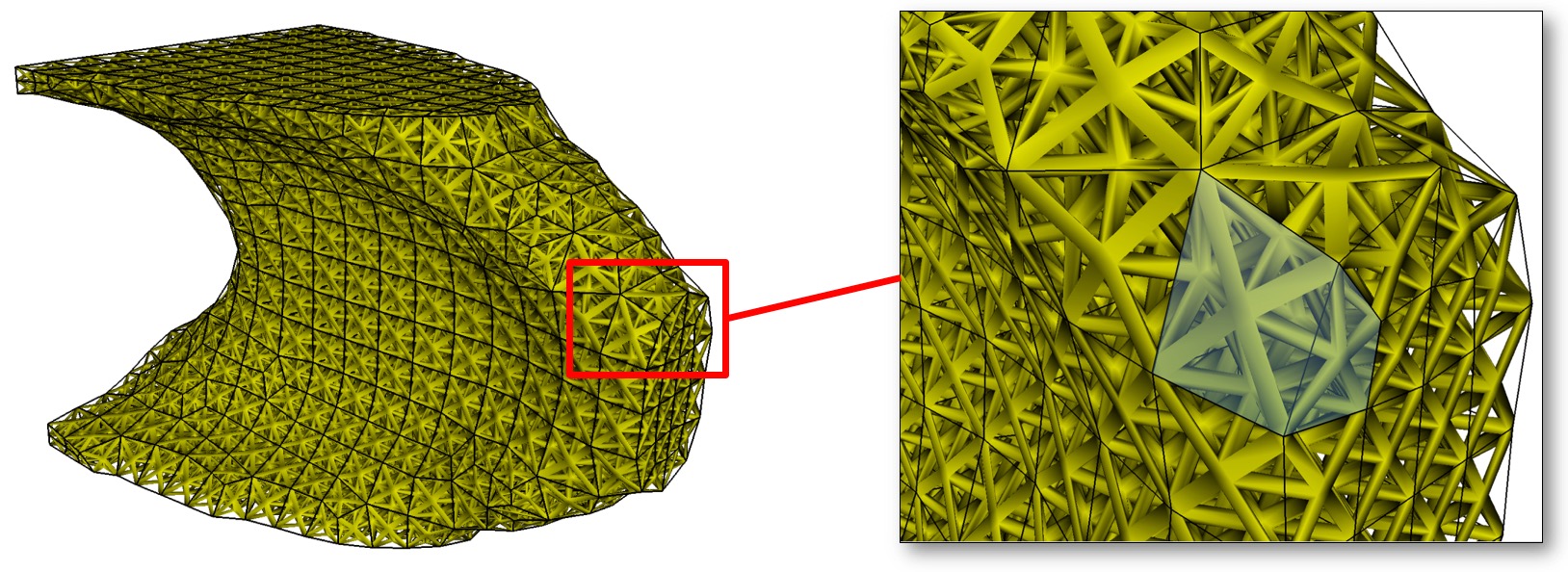

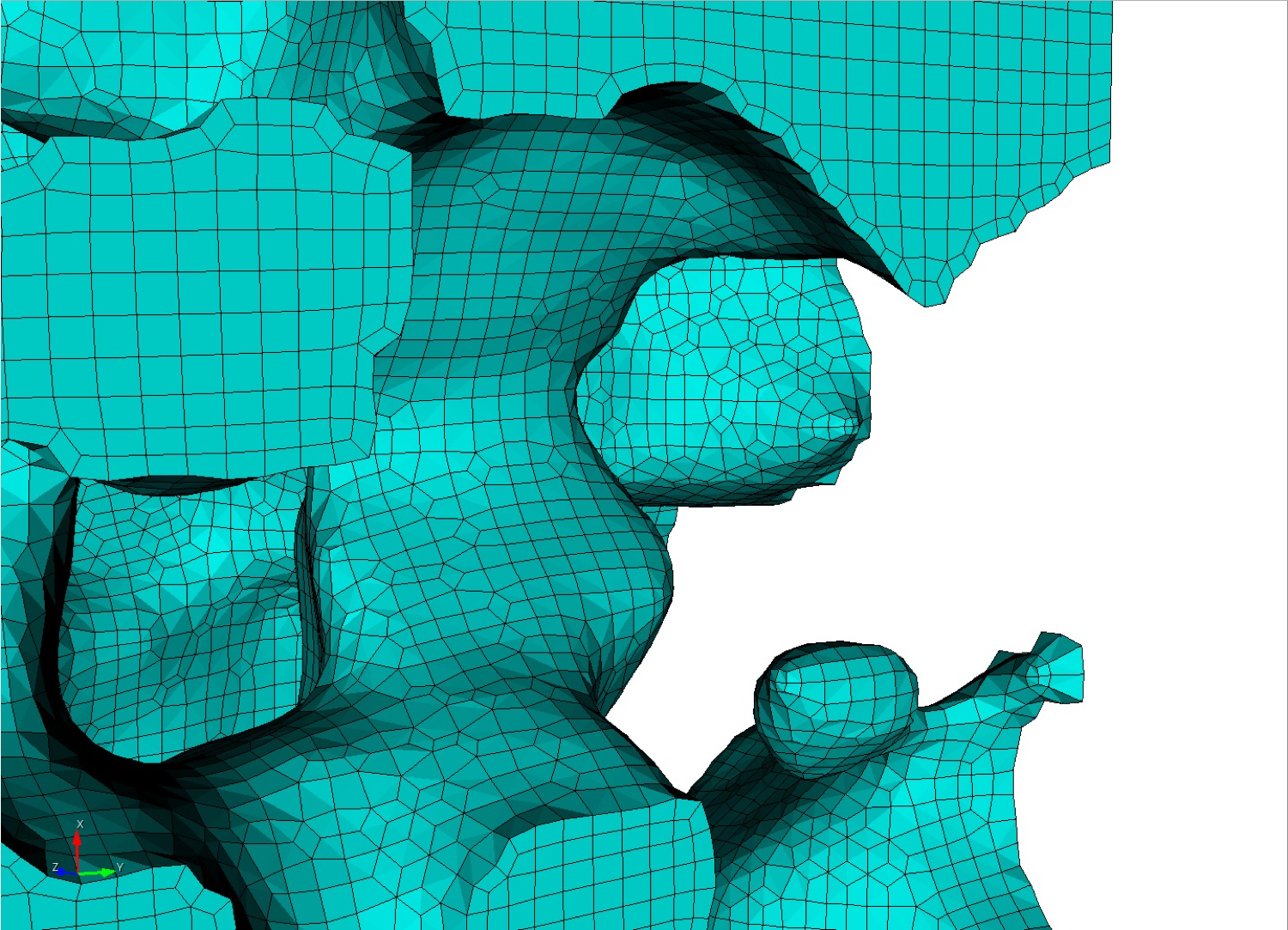

5.4.11.2 Sculpt Adaptive Meshing

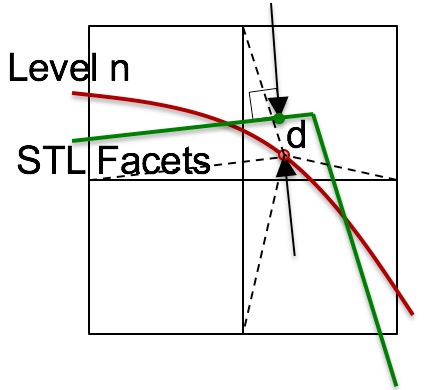

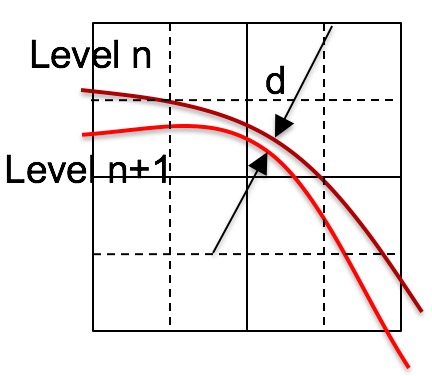

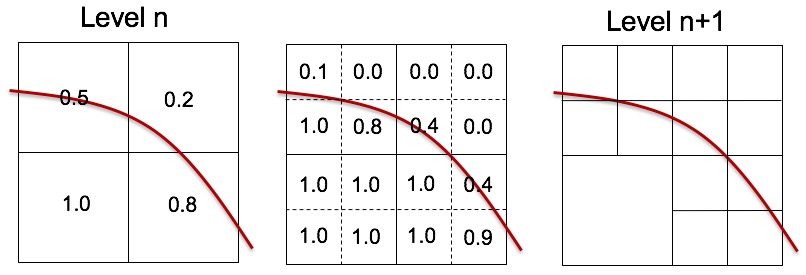

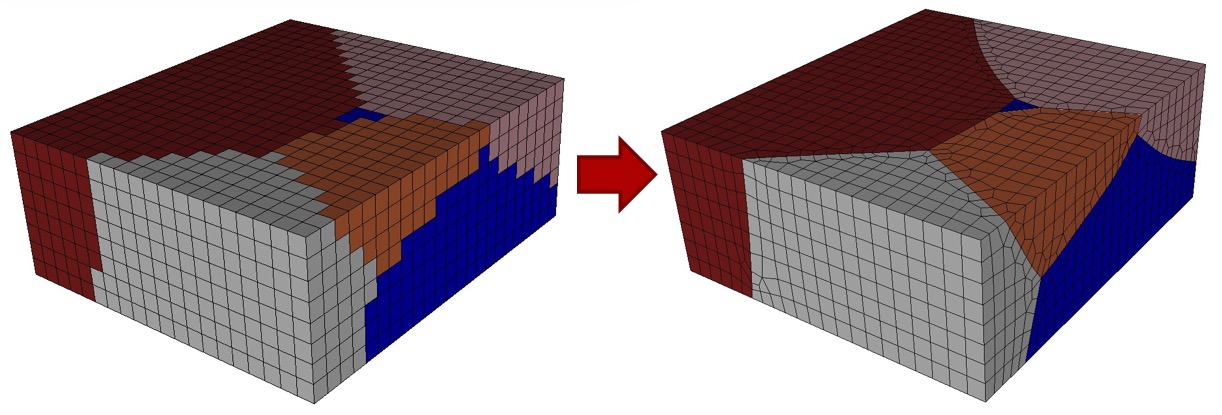

Sculpt options for specifying adaptive meshing. Sculpt uses an initial overlay Cartesian grid that serves as the basis for the all-hex mesh. The default mesh size will roughly follow the constant size cells of the overlay grid. The adaptivity option allows the user to automatically split cells of the Cartesian grid based on geometric criteria, resulting in smaller cells in regions with finer details. The adapted grid is then used as the basis for the Sculpt procedure.

Adaptive mesh begins with constant size coarse Cartesian grid. Cells are recursively split based on geometry criteria and transitions added between levels. Projections and smoothing are performed to improve element quality.

Three options are used for controlling the adaptivity in sculpt: adapt_type, adapt_levels and adapt_threshold. The adapt_type option controls the method and geometric criteria used for deciding which cells to split in the grid, while the adapt_levels option controls the the maximum number of times any one cell can be split. Depending upon the adapt_type selected, the adapt_threshold is used as the specific geometric threshold value at which the decision is made to split any given cell.

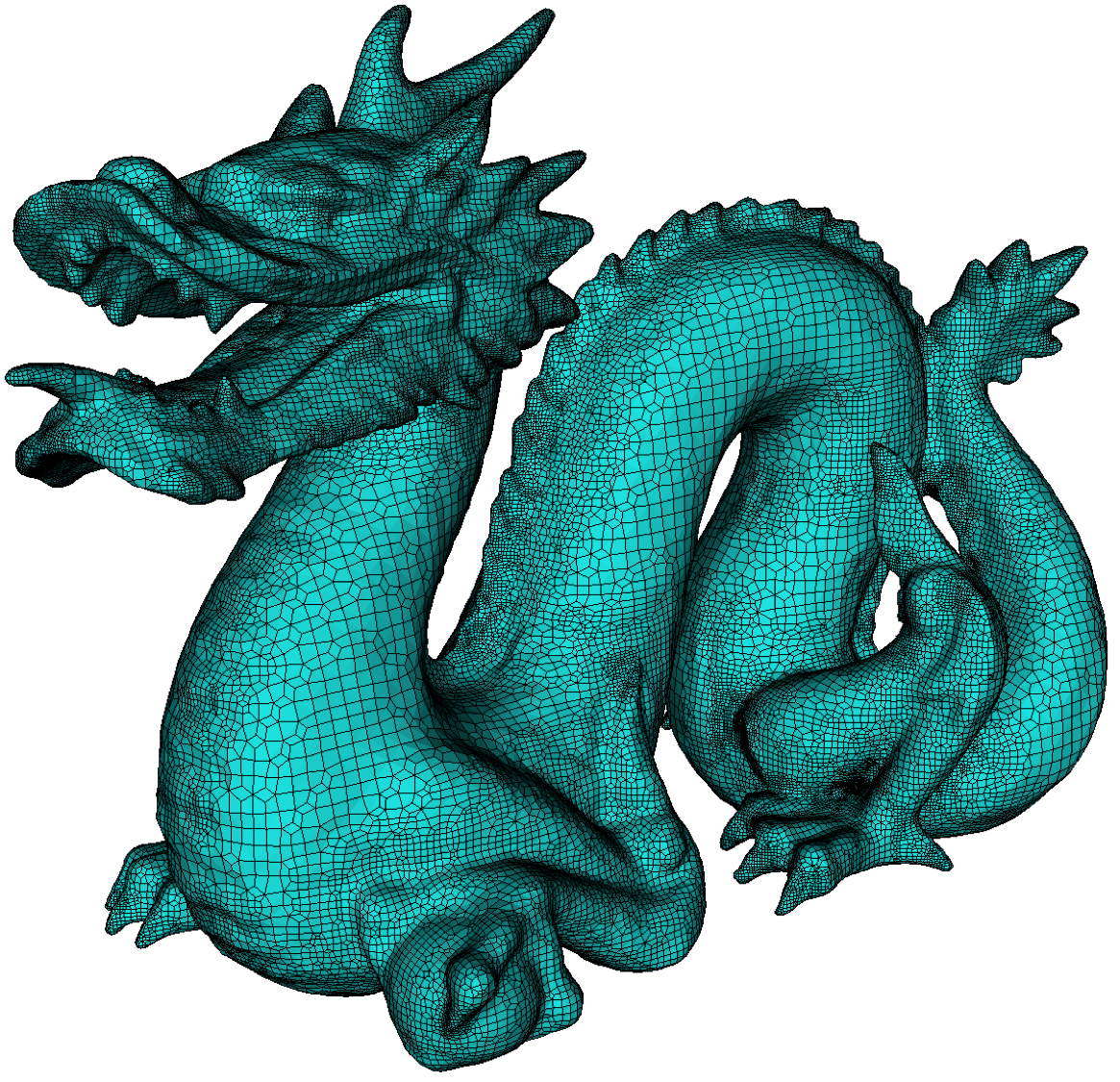

Figure 257: Initial cut-away view of adapted grid from dragon model before performing Sculpt operations.

Figure 258: The final mesh of the dragon model and cutaway view of the mesh is shown with up to 4 levels of adaptive refinement.

Adaptive Meshing --adapt -adp |

--adapt_type -A <arg> Adaptive meshing type |

--adapt_threshold -AT <arg> Threshold for adaptive meshing |

--adapt_levels -AL <arg> Number of levels of adaptive refinement |

--adapt_export -AE Export exodus mesh of refined grid |

--adapt_non_manifold -ANM Refine at non-manifold conditions |

5.4.11.2.1 Adaptive Refinement Type

ommand: adapt_type Adaptive meshing type |

Input file command: adapt_type <arg> |

Command line options: -A <arg> |

Argument Type: integer (0, 1, 2, 3, 4, 5) |

Input arguments: off (0) |

facet_to_surface (1) |

surface_to_facet (2) |

surface_to_surface (3) |

vfrac_average (4) |

coarsen (5) |

vfrac_diff (6) |

vfrac_difference (6) |

Command Description:

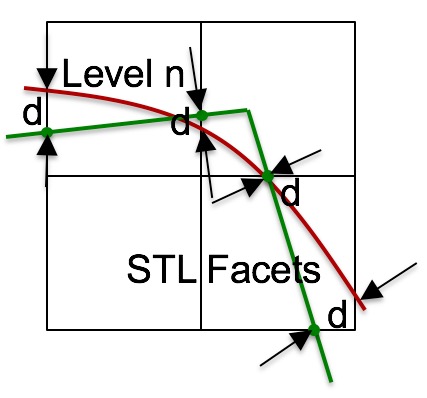

This option will automatically refine the mesh according to a user-defined criteria. Without this option, a constant cell size will be assumed everywhere in the model. To build the mesh, Sculpt uses an approximation to the exact geometry of the CAD model by interpolating mesh surfaces from volume fraction samples in each cell of the Cartesian grid. In general, the, higher the resolution of the Cartesian grid, the more sampling is done and the more accurate the mesh will represent the initial geometry. The adapt_type selected will control the criteria used for refining the mesh. If the criteria is not satisfied, the refinement will continue until a threshold indicated by the adapt_threshold parameter is satisfied everywhere, or the maximum number of levels (adapt_levels) is reached. The following criteria for refinement are available:

off (0): Cartesian grid is defined only by nelx, nely, and nelz or cell_size which is used as the basis for the sculpt mesh. No refinement will be performed.

facet_to_surface (1): This option will evaluate every location where an edge in the Cartesian grid intersects a triangle of the STL model and measures the closest distance to the approximated geometry. The cells adjacent to intersecting edges where the measured distance is greater than the adapt_threshold will be identified for uniform refinement. This is done for each refinement level where a new approximated geometry is then computed based upon the finer resolution grid. The refinement will continue until all measured distances are less than the adapt_threshold, or the maximum number of levels (adapt_levels) is reached. This option can only be used if input comes from an STL file. Microstructures and diatoms are currently not supported.

surface_to_facet (2): This criteria is similar to facet_to_surface (1) except that the locations selected for sampling are chosen from the vertices representing the approximated surfaces. The closest distance measured to any of the facets in the STL model is used as the criteria for refinement. Those cells at vertices where the distance measured exceeds the adapt_threshold are identified for refinement. This option is generally faster than 1, but may miss features if the initial resolution of the grid is too coarse. This option can also only be used if input geometry comes from an STL file. Microstructures and diatoms are currently not supported.

surface_to_surface (3): This criteria will test each cell to compute the local interpolated surface for the cell and compare with the surface interpolated for its eight subdivided child cells. If the distance between these two approximated surfaces is greater the the user defined adapt_threshold, then the cell will be uniformly refined. This option can be used with STL and diatom input geometry, but not with Microstructures.

vfrac_average (4): Each cell of the Cartesian grid is tested to determine if it should be subdivided into eight cells. The volume fraction of the parent cell is compared with the average volume fraction of its eight child cells. If the absolute difference between the average child volume fraction and its parent volume fraction is greater than the user defined adapt_threshold then the cell is uniformly refined. The adapt_threshold for this case should be a number between 0 and 1. A smaller number will be more sensitive to changes in geometry, usually resulting in more refinement at interfaces.

coarsen (5): Given a dense set of data on a Cartesian Grid, Sculpt will begin at a coarse resolution and refine to capture changes in the data. It uses the adapt_levels option to determine the coarseness of the initial grid. For example, a dense grid of LxMxN cells will begin with an initial resolution of L/2^a x M/2^a x N/2^a, where a is the user defined adapt_levels value. Cells will be identified for refinement if the volume fraction of any material in a cell is greater than the user defined adapt_threshold and less than 1.0-adapt_threshold. This option is available only for input_spn and input_micro formats. It is most useful for cases where very dense data is initially provided which would be too fine to serve as an FEA mesh. This method will effectively coarsen the mesh on the interior and exterior of solids, but maintain a fine resolution at geometry boundaries.

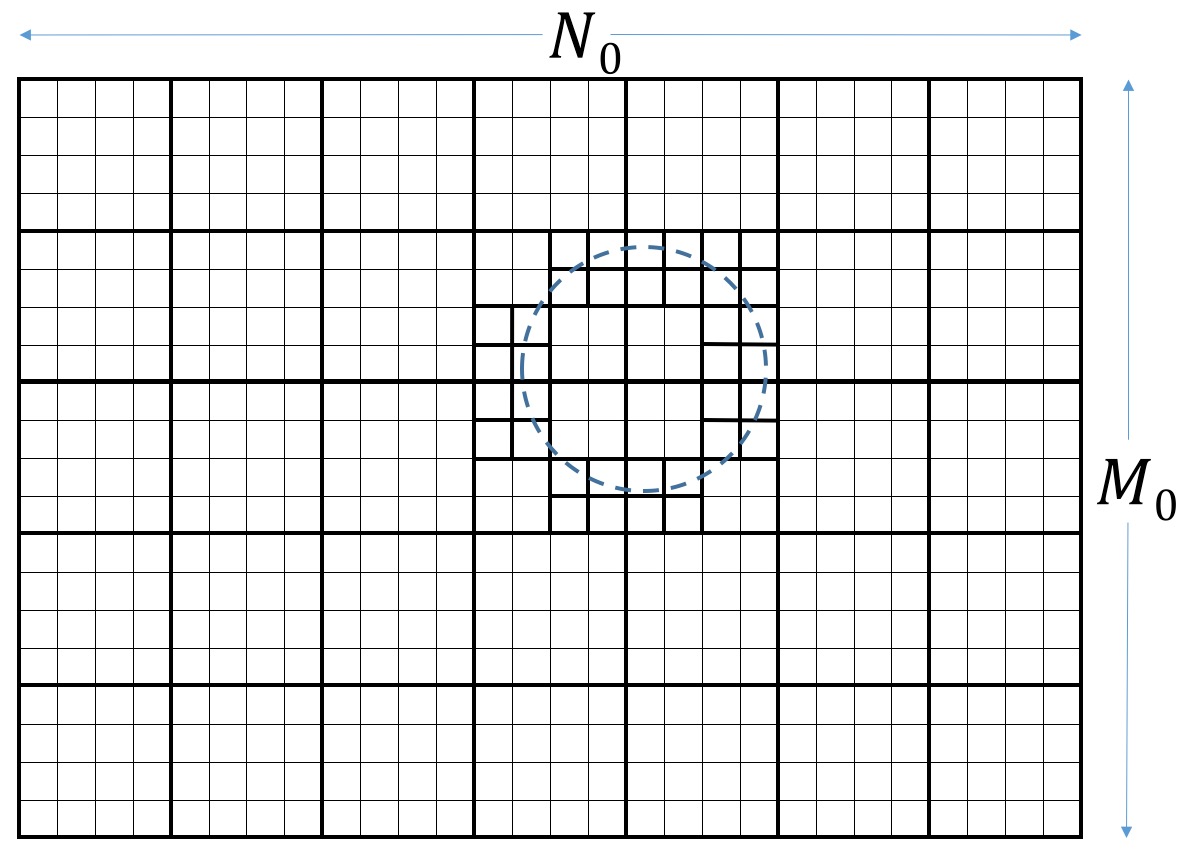

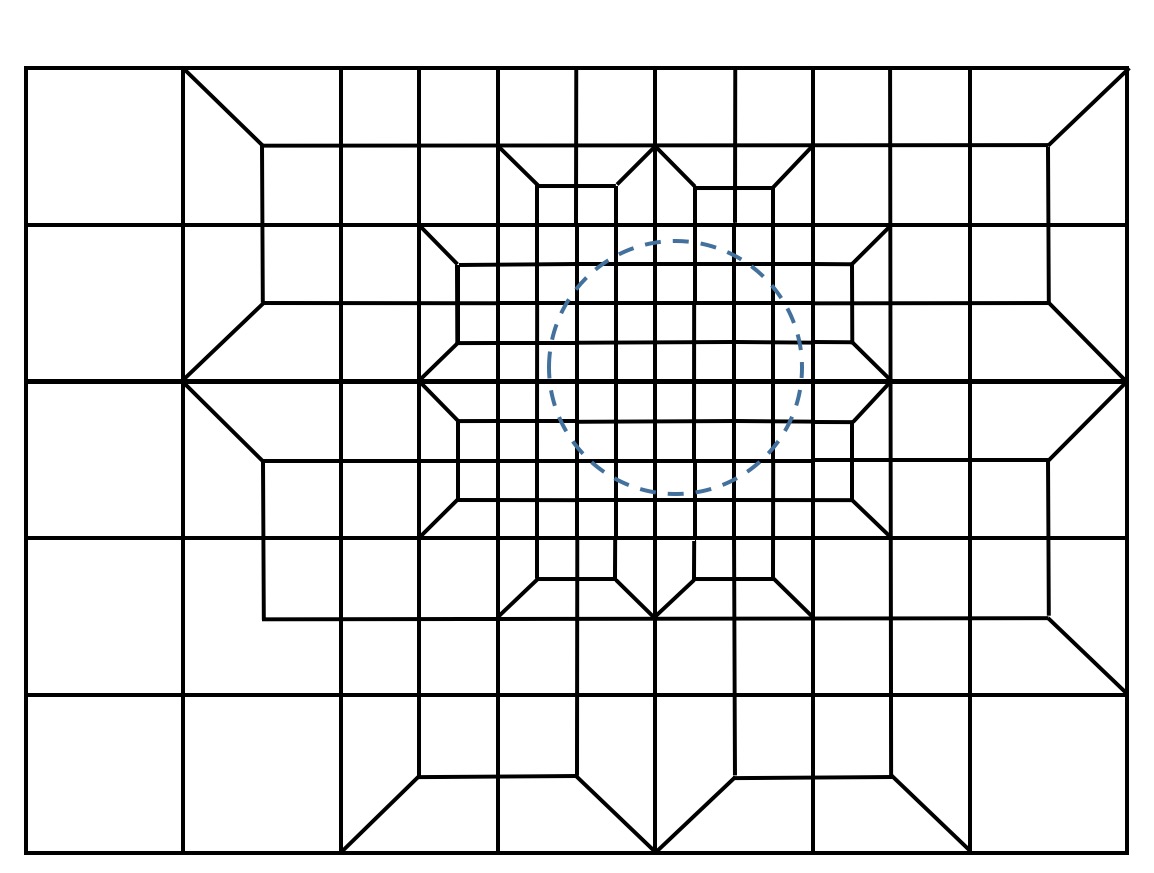

Refine to Dense Data (Coarsening). Initial grid at resolution N X M is coarsened to N0 X M0 based on the adapt_levels value. Coarse cells are then split similar to criteria in adapt_type = 4.

vfrac_difference (6): Each cell of the Cartesian grid is tested to determine if it should be subdivided into eight cells. The volume fraction of the parent cell is compared with each of the volume fractions of its eight child cells. If the absolute difference between any of the child volume fractions and its parent volume fraction is greater than the user defined adapt_threshold then the cell is uniformly refined. The adapt_threshold for this case should be a number between 0 and 1. A smaller number will be more sensitive to changes in geometry, usually resulting in more refinement at interfaces.

To maintain a conforming mesh, transition elements will be inserted to transition between smaller and larger element sizes. Default for the adapt_type option is off (0) (or that no adaptive refinement will take place).

In all cases the initial Cartesian grid defined by xint, yint and zint or the cell_size value will be used as the basis for refinement and will define the approximate largest element size in the mesh.

5.4.11.2.2 Adaptive Refinement Threshold

Command: adapt_threshold Threshold for adaptive meshing |

Input file command: adapt_threshold <arg> |

Command line options: -AT <arg> |

Argument Type: floating point value >= 0.0 |

Command Description:

This value controls the sensitivity of of the adaptivity. The value used should be based upon the adapt_type:

adapt_threshold = 0.25 * cell_size / adapt_levels^2 |

The adapt_threshold value in this case represents the maximum difference in volume fraction between a parent cell and the average of its eight child cells. This value should be between 0.0 and 1.0. The smaller the number, the more sensitive will be the adaptation and the greater the number of resulting elements. A default adapt_threshold of 0.01 is used if not specified.

facet_to_surface (1)

surface_to_facet (2)

surface_to_surface (3)

vfrac_average (4)

coarsen (5)

Note that the user defined adapt_threshold may not be satisfied everywhere in the mesh if the value defined for adapt_levels is exceeded.

5.4.11.2.3 Number of Adaptive Levels

Command: adapt_levels Number of levels of adaptive refinement |

Input file command: adapt_levels <arg> |

Command line options: -AL <arg> |

Argument Type: integer >= 0 |

Command Description:

number of cells = 8^adapt_levels |

min cell edge length = cell_size / adapt_levels^2 |

The actual number of refinement levels used will be determined by whether all cells meet the adapt_threshold, or the adapt_levels value is exceeded. The default adapt_levels is 2. Note that setting the adapt_levels more than 4 or 5 can result in long compute times.

5.4.11.2.4 Export Refined Cartesian Grid

Command: adapt_export Export exodus mesh of refined grid |

Input file command: adapt_export |

Command line options: -AE |

Command Description:

Export an exodus mesh containing the refined Cartesian grid. Interface reconstruction, boundary layer insertion and smoothing have not yet been applied to this mesh. It is the base mesh used as input to Sculpt. One file per processor will be exported in the form "vfrac_adapt.e.x.x". The exodus mesh produced will also contain the computed volume fractions for each material present in the model represented as element variables.

This option is primarily used for debugging the refinement option. However the mesh produced with this option can be used as the base mesh when used with the input_mesh option. For example, instead of Cartesian grid options, the input mesh may be specified as input_mesh = vfrac_adapt.e.1.0. Sculpt will use the refined mesh and the volume fraction element variables to build the final mesh.

5.4.11.2.5 Adapt Cells at Non-manifold Nodes

Command: adapt_non_manifold Refine at non-manifold conditions |

Input file command: adapt_non_manifold |

Command line options: -ANM |

Command Description:

If refinement results in a non-manifold condition at a node, the surrounding cells will be identified for refinement. In some cases, using this option will result in a closer match to geometry for thin layers or small features. Using this option will normally result in more elements at material interfaces. Note that in all cases non-manifold conditions will be resolved even without this option in a subsequent step, however without this option, the resulting solution may not match geometry as accurately.

The adapt_non_manifold option is off by default. It is currently only implemented for adapt_type that use an STL geometry definition. (adapt_type = 1,2,3)

5.4.11.3 Sculpt Application

This page describes the Sculpt application, a separate companion application to Cubit designed to run in parallel for generating all-hex meshes of complex geometry. Sculpt was developed as a separate application so that it can be run independently from Cubit on high performance computing platforms. It was also designed as a separable software library so it can be easily integrated as an in-situ meshing solution within other codes. As installed with Cubit, Sculpt can be set up and run directly from Cubit, in a batch process from the unix command line or from a user-defined input file. This documentation describes the input file and command line syntax for the Sculpt Application when running in batch mode. See this page for using Cubit to set up input for Sculpt. A brief technical description of Sculpt may also be found here.

5.4.11.3.1 Sculpt System Requirements

Sculpt is currently built for windows, linux and mac operating systems. Current supported OS versions should be the same as those supported by Cubit. It is designed to take advantage of 64 bit multicore and distributed memory computers, using open-mpi as the basis for parallel communications.

5.4.11.3.2 Running Sculpt

Sculpt can be run using one of two excutables:

psculpt requires the use of mpiexec to start the process. Number of processors to use is specified by the -np argument to mpiexec. psculpt and its input parameters are also used as input to mpiexec. For example:

mpiexec -np 8 psculpt -stl myfile.stl -cs 0.5 |

If appropriate system paths have not been set, you may need to use full paths when referring to mpiexec and psculpt.

This application assumes that mpiexec is included in the standard CUBIT installation directory. The number of processors to use is specified by the -j option. For example: sculpt -j 8 -stl myfile.stl -cs 0.5 If the -j option is not used, sculpt will default to a single processor for execution. The -mpi option can also be used with the sculpt application to indicate a specific mpi installation that is not included with CUBIT. For example:

sculpt -j 8 -mpi /path/to/mpiexec -stl myfile.stl -cs 0.5 |

5.4.11.3.3 Sculpt Examples

The following illustrate simple use cases of the Sculpt application. To use these examples, copy the following stl and diatom files to your working directory:

brick1.stl

brick2.stl

bricks.diatom

5.4.11.3.3.1 Example 1

sculpt -j 4 -stl brick1.stl -cs 0.5

brick1.stl_results.e.4.0 |

brick1.stl_results.e.4.1 |

brick1.stl_results.e.4.2 |

nbrick1.stl_results.e.4.3 |

epu -p 4 brick1.stl_results |

brick1.stl_results.e |

To view the resulting mesh in Cubit, use the import free mesh command. For example:

import mesh "brick1.stl_results.e" no_geom |

5.4.11.3.3.2 Example 2

mpiexec -np 4 psculpt -x 46 -y 26 -z 26 -t -6.5 -u -6.5 -v -6.5 -q 16.5 -r 6.5 -s 6.50 -d bricks.diatom |

In this case we use mpiexec to start 4 processes of psculpt. We explicitly define the number of Cartesian intervals and the dimensions of the grid. Rather than using the -stl option, we use the -d option which allows us to specify the diatom file, bricks.diatom. This file allows us to specify multiple stl files, where each one represents a different material. In this case we use both brick1.stl and brick2.stl, which are called out in bricks.diatom.

5.4.11.4 Sculpt Boundary Conditions

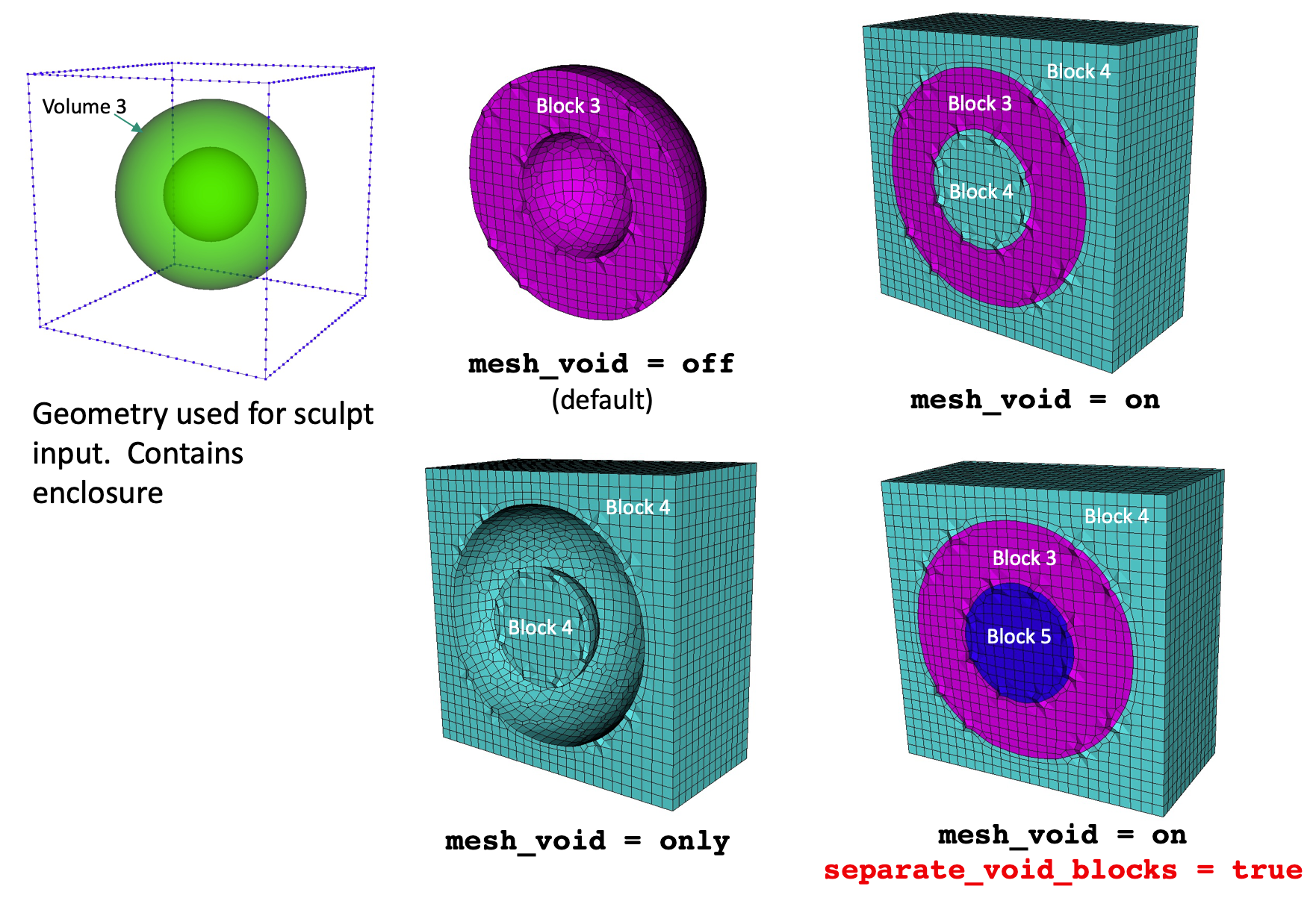

Sculpt options for specifying the methods for generating nodesets, sidesets and blocks on the mesh. Several automatic methods for generating nodesets and sidesets are provided in Sculpt using the gen_sidesets option. Where multiple blocks are required, Block IDs are normally defined using the material ID in the diatom file. Each STL file can be associated with a different block ID. If the mesh_void option is used, the ID for the block of elements in the void region can be set using the void_mat option.

oundary Conditions --boundary_condition -bc |

--void_mat -VM <arg> Void material ID (when mesh_void=true) |

--separate_void_blocks -SVB Separate void into unique block IDs |

--gen_sidesets -SS <arg> Generate sidesets |

--free_surface_sideset -FS <arg> Free Surface Sideset |

--match_sidesets -mss <arg> Sidesets ids of matching pairs |

5.4.11.4.1 Void Material ID

Command: void_mat Void material ID (when mesh_void=true) |

|

Input file command: void_mat <arg> |

Command line options: -VM <arg> |

Argument Type: integer > 0 |

Command Description:

When the mesh_void option is used, this value is the material (block) ID assigned to all elements in the void region. If void_mat option is not used, the material ID of elements in the void region will be the maximum material ID in the model + 1. Note that the void_mat may be the same as an existing material in another part of the model.

5.4.11.4.2 Separate Void Blocks

ommand: separate_void_blocks Separate void into unique block IDs |

|

Input file command: separate_void_blocks |

Command line options: -SVB |

Command Description:

5.4.11.4.3 Generate Sidesets

Command: gen_sidesets Generate sidesets |

|

Input file command: gen_sidesets <arg> |

Command line options: -SS <arg> |

Argument Type: integer (0, 1, 2, 3, 4, 5) |

Input arguments: off (0) |

fixed (1) |

variable (2) |

geometric_surfaces (3) |

geometric_sidesets (4) |

rve (5) |

input_mesh_and_stl (6) |

input_mesh_and_free_surfaces (7) |

rve_variable (8) |

Generate exodus sidesets using one of the following options:

off (0): No sidesets will be generated

fixed (1): Exactly 3 sidesets will be generated according to the following:

Sideset 1: All sides at the domain boundary. Sides will only be present in this sideset if the model intersects the enclosing bounding box or the void option is used.

Sideset 2: All sides at the model boundary. Any side on the model that is not interior will be included. This should represent a full enclosure of the model if it does not intersect the domain boundary.

Sideset 3: All sides at material interfaces. Includes sides on the interior where adjacent blocks are different.

variable (2): A variable number of sidesets will be generated with the following characteristics:

Surfaces at the domain boundary

Exterior material surfaces

Interfaces between materials

surface |

1 0 1 2 3 4 5 6 7 8 9 |

10 11 12 13 14 15 16 17 18 19 |

20 21 22 23 |

endsurface 1 |

Nodeset/Sideset ID Contains nodes/faces |

1 on minimum X domain boundary |

2 on maximum X domain boundary |

3 on minimum Y domain boundary |

4 on maximum Y domain boundary |

5 on minimum Z domain boundary |

6 on maximum Z domain boundary |

In addition, a nodeset and sideset will be generated on interior surfaces for each unique pair of adjacent material IDs. One final nodeset will also be generated along interior curves at all internal triple junctions (curves where at least 3 surfaces share a common curve).

Figure 272: Example of automatically defined sidesets at domain boundaries of an RVE and at all interface surfaces between materials.

Figure 273: Example of sidesets defined in the input mesh and corresponding domain boundary sidesets in the output mesh.

Figure 274: Example of sidesets defined in the input mesh and corresponding domain boundary sidesets in the output mesh.

rve_variable (8): Nodesets 1-6 and Sidesets 1-6 are defined at the boundaries as described in the gen_sidesets = rve (5) option. With the rve_variable option, additional nodesets and sidesets at material interfaces on the interior of the mesh are defined similar to the gen_sidesets = variable (2) option. Grouping of interior sides in a sidesets will be contiguous, where a separate sideset will be generated for each unique set of contiguous sides. Nodesets will be generated in a similar manner.

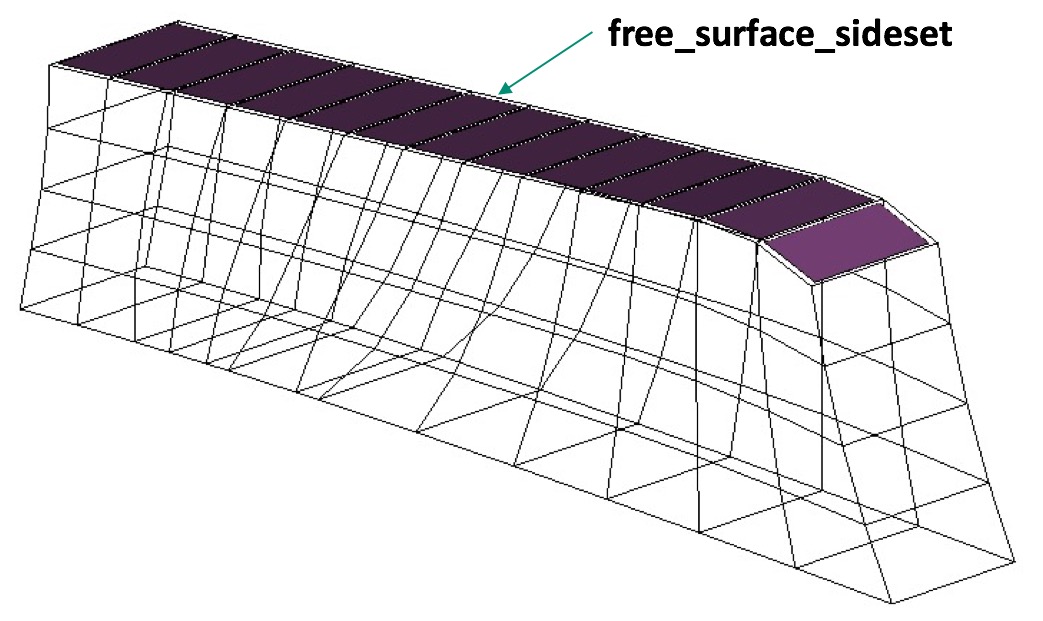

5.4.11.4.4 Free Surface Sidesets

Command: free_surface_sideset Free Surface Sideset |

|

Input file command: free_surface_sideset <arg> |

Command line options: -FS <arg> |

Argument Type: integer(s) >= 0 |

Command Description:

Given exodus sidesets are treated as interior surfaces for STL projection.

5.4.11.4.5 Match Sideset Ids

Command: match_sidesets Sidesets ids of matching pairs |

|

Input file command: match_sidesets <arg> |

Command line options: -mss <arg> |

Argument Type: integer(s) >= 0 |

Command Description:

If used with an unstructured base grid (input mesh), this option allows the user to define a crack in the input mesh, where the faces of each vertical side (wall) of the crack are each in a different sideset. The faces at the bottom of the crack share a common edge (V-bottom) or face (square-bottom). Sculpt will match or equalize the volume fractions of the bottom cells on either side of the crack. This produces a uniform, higher quality mesh at the crack. The sidesets must be specified in a pairwise order. This option must be used with the –input_mesh (-im) option.

5.4.11.5 Sculpt Boundary Layers

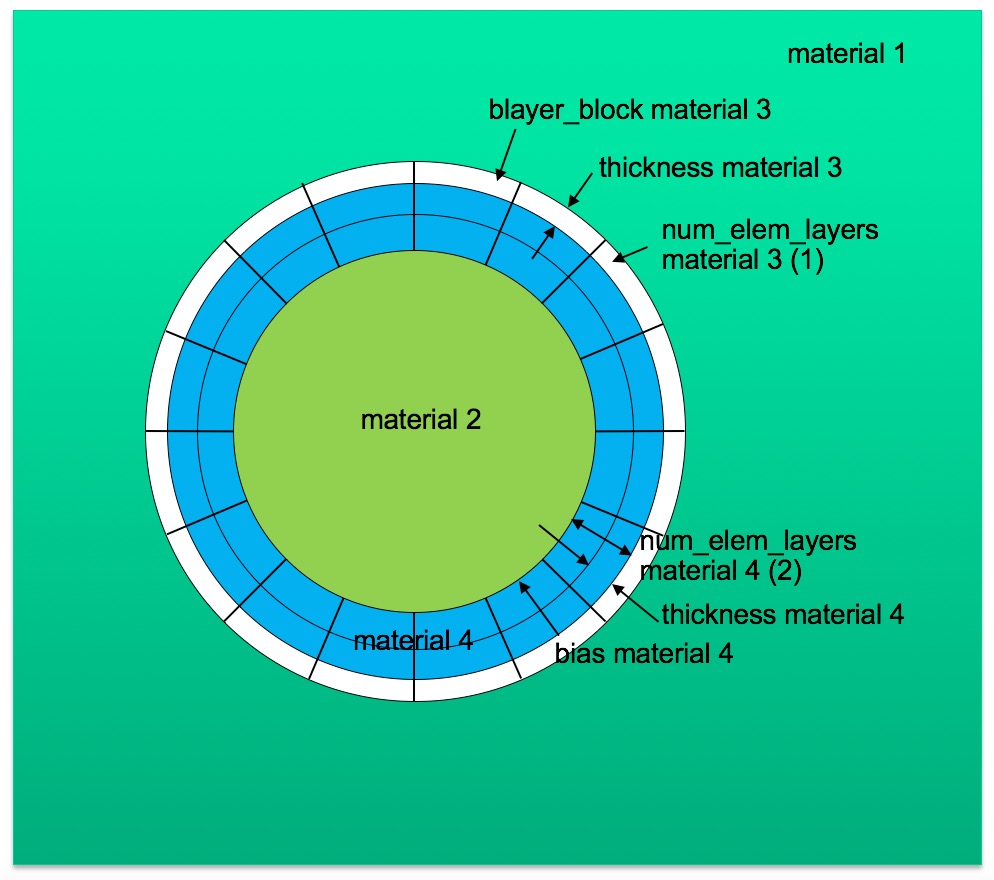

Figure 277: Boundary layers defined at the surfaces of a material.

Boundary Layers --boundary_layer -bly |

--begin -beg <arg> Begin specification blayer or blayer_block |

--end -zzz <arg> End specification blayer or blayer_block |

--material -mat <arg> Boundary layer material specification |

--num_elem_layers -nel <arg> Number of element layers in blayer block |

--thickness -th <arg> Thickness of first element layer in block |

--bias -bi <arg> Bias of element thicknesses in blayer block |

5.4.11.5.1 Boundary Layer Begin

Command: begin Begin specification blayer or blayer_block |

Input file command: begin <arg> |

Command line options: -beg <arg> |

Argument Type: blayer, blayer_block |

Command Description:

Defines the beginning of a specification block. Must be closed with "end" argument. Currently supports the following specifications:

blayer

Defines a boundary layer specification. Layers of hex elements are placed at the interface of a given material. Valid argumnts used within a blayer specification include: material, and begin blayer_block.

blayer_block

Defines a set of element layers within a given blayer definition that share a common material ID. Valid arguments used within a blayer_block specification include: material, num_elem_layers, thickness and bias.

The following example shows a boundary layer specification in a sculpt input file. In this example, two boundary layer blocks are defined at the interface of materials 1 and 2. Two material blocks with ID 3 and 4 are generated with 1 and 2 element layers respectively.

BEGIN BLAYER |

MATERIAL = 1 2 |

BEGIN BLAYER_BLOCK |

MATERIAL = 3 |

NUM_ELEM_LAYERS = 1 |

THICKNESS = 0.1 |

END BLAYER_BLOCK |

BEGIN BLAYER_BLOCK |

MATERIAL = 4 |

NUM_ELEM_LAYERS = 2 |

THICKNESS = 0.2 |

BIAS = 1.3 |

END BLAYER_BLOCK |

END BLAYER |

5.4.11.5.2 Boundary Layer End

Command: end End specification blayer or blayer_block |

Input file command: end <arg> |

Command line options: -zzz <arg> |

Argument Type: blayer, blayer_block |

Command Description:

Defines the end of a specification block. Must be preceded with "begin" argument. Currently supports arguments blayer and blayer_block.

5.4.11.5.3 Boundary Layer Material

Command: material Boundary layer material specification |

Input file command: material <arg> |

Command line options: -mat <arg> |

Argument Type: integer > 0 |

Command Description:

Defines a material ID in a boundary layer specification. When used within a BLAYER specification, it references one or two existing materials in the input where boundary layers will be generated. If a single material is specified, hex layers will be generated at all interfaces of the designated material with any adjacent material. If two material IDs are specified, layers will be generated only at interfaces where the two materials are adjacent.

In most cases, the material ID(s) in the BLAYER specification refer to material IDs defined in the diatom file for specific geometry inserts such as STL files or diatom primitives. It can also be defined as the void material ID (VOID_MAT) or a material in a volume fraction description such as input_vfrac, input_micro, input_cart_exo or input_spn.

When used within a BLAYER_BLOCK specification, it refers to a new block that will be generated for which all elements in the blayer_block will be assigned. Normally it refers to a unique material ID that is not already referenced in the input. Where the material ID is already used, elements in the blayer block will be added to the existing material.

A material ID must be defined for both a BLAYER and BLAYER_BLOCK. This value does not have a default.

5.4.11.5.4 Number of Element Layers in Boundary Layer

Command: num_elem_layers Number of element layers in blayer block |

Input file command: num_elem_layers <arg> |

Command line options: -nel <arg> |

Argument Type: integer > 0 |

Command Description:

Number of element layers to be defined within a BLAYER_BLOCK specification. num_elem_layers must be defined for all BLAYER_BLOCKs.

5.4.11.5.5 Boundary Layer Thickness

ommand: thickness Thickness of first element layer in block |

Input file command: thickness <arg> |

Command line options: -th <arg> |

Argument Type: floating point value |

Command Description:

Thickness of the first layer defined in a BLAYER_BLOCK. Value is an absolute distance. No default is provided and must be defined for all BLAYER_BLOCKs

5.4.11.5.6 Boundary Layer Bias

Command: bias Bias of element thicknesses in blayer block |

Input file command: bias <arg> |

Command line options: -bi <arg> |

Argument Type: floating point value |

Command Description:

Bias factor applied to additional layers of a BLAYER_BLOCK. Used in conjunction with the THICKNESS parameter (thickness of first layer) it defines a multiplier for the thickness for subsequent element layers defined within the same BLAYER_BLOCK. Default BIAS is 1.0 and is optional.

5.4.11.6 Sculpt Command Summary

Following is a listing of the available input commands to either sculpt or psculpt. When used from the unix command line, commands may be issued using the short form argument, designated with a single dash(-), or with the longer form, designated with two dashes (–). When used in an input file, only the long form may be used, omitting the two dashes (–)

Process Control --process -pc |

--num_procs -j <arg> Number of processors requested |

--input_file -i <arg> File containing user input data |

--debug_processor -D <arg> Sleep to attach to processor for debug |

--debug_flag -dbf <arg> Dump debug info based on flag |

--quiet -qt Suppress output |

--print_input -pi Print input values and defaults then stop |

--version -vs Print version number and exit |

--threads_process -tpp <arg> Number of threads per process |

--iproc -ip <arg> Number of processors in I direction |

--jproc -jp <arg> Number of processors in J direction |

--kproc -kp <arg> Number of processors in K direction |

--periodic -per Generate periodic mesh |

--check_periodic -cp <arg> Check for periodic geometry |

--check_periodic_tol -cpt <arg> Tolerance for checking periodicity |

--periodic_axis -pax <arg> Axis periodicity is about |

--periodic_nodesets -pns <arg> Nodesets ids of master/slave nodesets |

--build_ghosts -bg Write ghost layers to exodus files for debug |

--vfrac_method -vm <arg> Set method for computing volume fractions |

|

Input Data Files --input -inp |

--stl_file -stl <arg> Input STL file |

--diatom_file -d <arg> Input Diatom description file |

--input_vfrac -ivf <arg> Input from Volume Fraction file base name |

--input_micro -ims <arg> Input from Microstructure file |

--input_cart_exo -ice <arg> Input from Cartesian Exodus file |

--input_spn -isp <arg> Input from Microstructure spn file |

--spn_xyz_order -spo <arg> Ordering of cells in spn file |

--lattice -l <arg> STL Lattice Template File |

|

Output --output -out |

--exodus_file -e <arg> Output Exodus file base name |

--volfrac_file -vf <arg> Output Volume Fraction file base name |

--quality -Q Dump quality metrics to file |

--export_comm_maps -C Export parallel comm maps to debug exo files |

--write_geom -G Write geometry associativity file |

--write_mbg -M Write mesh based geometry file <beta> |

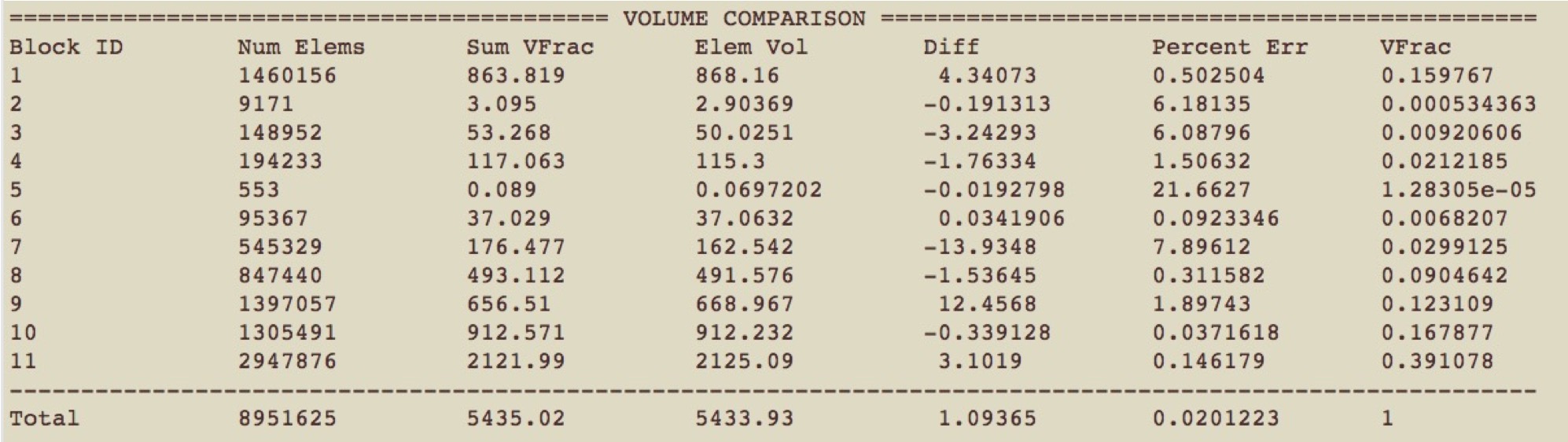

--compare_volume -cv Report vfrac and mesh volume comparison |

--compute_ss_stats -css Report sideset statistics |

|

Overlay Grid Specification --overlay -ovr |

--nelx -x <arg> Num cells in X in overlay Cartesian grid |

--nely -y <arg> Num cells in Y in overlay Cartesian grid |

--nelz -z <arg> Num cells in Z in overlay Cartesian grid |

--xmin -t <arg> Min X coord of overlay Cartesian grid |

--ymin -u <arg> Min Y coord of overlay Cartesian grid |

--zmin -v <arg> Min Z coord of overlay Cartesian grid |

--xmax -q <arg> Max X coord of overlay Cartesian grid |

--ymax -r <arg> Max Y coord of overlay Cartesian grid |

--zmax -s <arg> Max Z coord of overlay Cartesian grid |

--cell_size -cs <arg> Cell size (nelx, nely, nelz ignored) |

--align -a Automatically align geometry to grid |

--bbox_expand -be <arg> Expand tight bbox by percent |

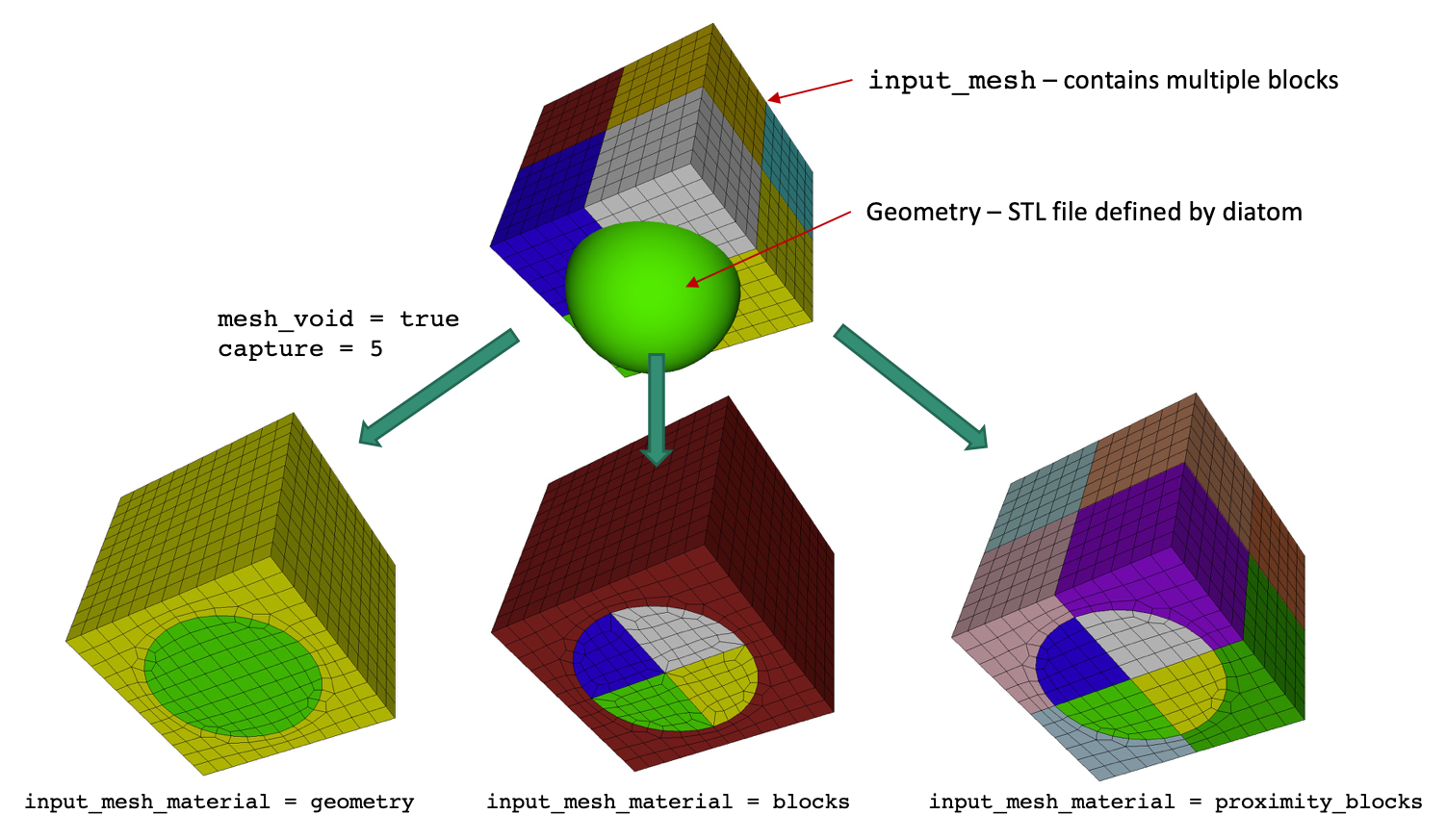

--input_mesh -im <arg> Input Base Exodus mesh |

--input_mesh_blocks -imb <arg> Block ids of Input Base Exodus mesh |

--input_mesh_material -imm <arg> Material definition with input mesh |

--input_mesh_pamgen -imp <arg> Input Base mesh defined by Pamgen |

|

Mesh Type --type -typ |

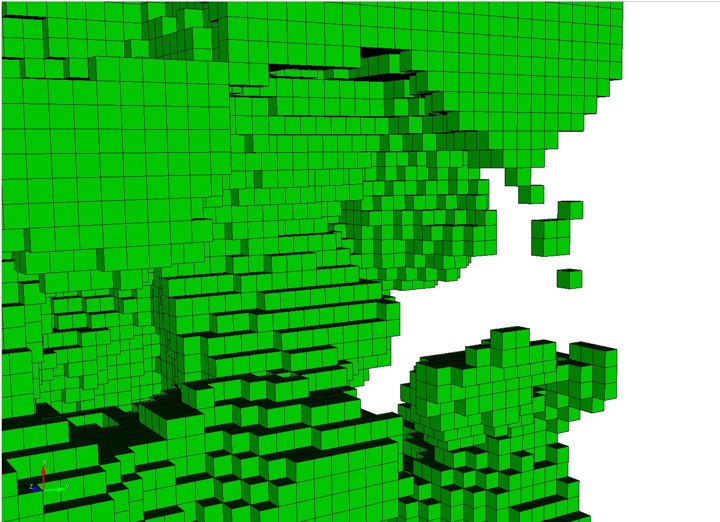

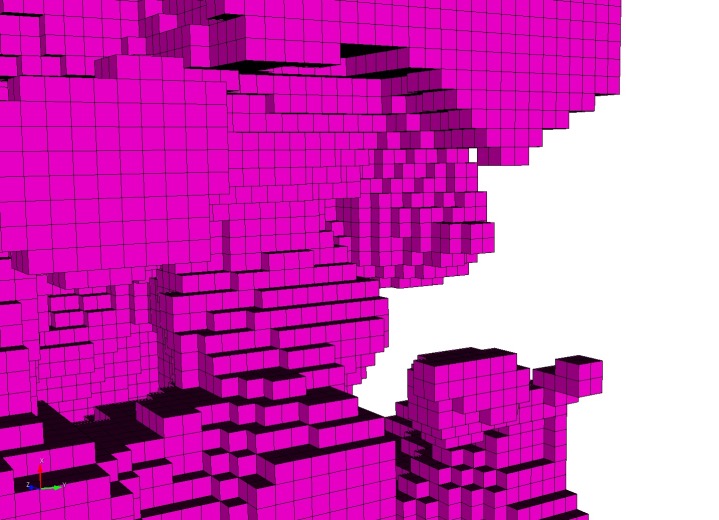

--stair -str <arg> Generate Stair-step mesh |

--mesh_void -V <arg> Mesh void |

--trimesh -tri Generate tri mesh of geometry surfaces |

--tetmesh -tet <arg> Under Development |

--deg_threshold -dg <arg> Convert hexes below threshold to degenerates |

--max_deg_iters -dgi <arg> Maximum number of degenerate iterations |

--htet -ht <arg> Convert hexes below quality threshold to tets |

--htet_method -hti <arg> Method used for splitting hexes to tets |

--htet_material -htm <arg> Convert hexes in given materials to tets |

--htet_transition -htt <arg> Transition method between hexes and tets |

--htet_pyramid -htp <arg> Local transition pyramid |

--htet_tied_contact -htc <arg> Local transition tied contact |

--htet_no_interface -htn <arg> Local transition none |

|

Boundary Conditions --boundary_condition -bc |

--void_mat -VM <arg> Void material ID (when mesh_void=true) |

--separate_void_blocks -SVB Separate void into unique block IDs |

--gen_sidesets -SS <arg> Generate sidesets |

--free_surface_sideset -FS <arg> Free Surface Sideset |

--match_sidesets -mss <arg> Sidesets ids of matching pairs |

|

Adaptive Meshing --adapt -adp |

--adapt_type -A <arg> Adaptive meshing type |

--adapt_threshold -AT <arg> Threshold for adaptive meshing |

--adapt_levels -AL <arg> Number of levels of adaptive refinement |

--adapt_export -AE Export exodus mesh of refined grid |

--adapt_non_manifold -ANM Refine at non-manifold conditions |

|

Smoothing --smoothing -smo |

--smooth -S <arg> Smoothing method |

--csmooth -CS <arg> Curve smoothing method |

--laplacian_iters -LI <arg> Number of Laplacian smoothing iterations |

--max_opt_iters -OI <arg> Max. number of parallel Jacobi opt. iters. |

--opt_threshold -OT <arg> Stopping criteria for Jacobi opt. smoothing |

--curve_opt_thresh -COT <arg> Min metric at which curves won't be honored |

--max_pcol_iters -CI <arg> Max. number of parallel coloring smooth iters. |

--pcol_threshold -CT <arg> Stopping criteria for parallel color smooth |

--max_gq_iters -GQI <arg> Max. number of guaranteed quality smooth iters. |

--gq_threshold -GQT <arg> Guaranteed quality minimum SJ threshold |

--geo_smooth_max_deviation -GSM <arg> Geo Smoothing Maximum Deviation |

|

Mesh Improvement --improve -imp |

--pillow -p <arg> Set pillow criteria (1=surfaces) |

--pillow_surfaces -ps Turn on pillowing for all surfaces |

--pillow_curves -pc Turn on pillowing for bad quality at curves |

--pillow_boundaries -pb Turn on pillowing at domain boundaries |

--pillow_curve_layers -pcl <arg> Number of elements to buffer at curves |

--pillow_curve_thresh -pct <arg> S.J. threshold to pillow hexes at curves |

--pillow_smooth_off -pso Turn off smoothing following pillow operations |

--capture -c <arg> Project to facet geometry <beta> |